Heating and gas supply must be completely sealed. It is practically impossible to achieve this only due to the quality of the thread itself, without the use of additional materials. There are several ways to seal, but recently anaerobic sealant for threaded joints has gained immense popularity among craftsmen. Why?

Naturally, the main task of such seals is the complete sealing of joints. The material used must completely prevent leakage of water or gas through the threaded gap. But a high-quality sealant must also have other important properties:

- It should not contribute to the corrosion of the connected elements. On the contrary, the material applied to seal the threaded joints is designed to protect these vulnerable points from destruction caused by exposure to water or aggressive substances.

- All sealing materials, including sealants, must have good adhesive properties to prevent them from being squeezed out of joints under the pressure of water or gas.

- It must be resistant to temperature extremes, withstand vibration fluctuations.

- The materials used to seal the pipes should not significantly impede the assembly or disassembly of the connection. It is very convenient if, after dismantling, the seal can be easily removed and reapplied.

Another important feature that you should pay attention to when choosing a sealant or sealant for threads is ease of use. Very often, such connections are located in hard-to-reach places where any manipulations are difficult. In such cases, sealants have a clear advantage, as they do not require such careful and careful application as sealing tapes or flax.

Sealing with linen thread

This method is the oldest. This is how pipe joints were sealed in Soviet apartments. If there are no other sealants in the store, then flax and plumbing paste will certainly be found. But this seal has a number of significant drawbacks:

- According to the rules, flax is used in combination with drying oil and red lead. Lead prevents corrosion of the joint, and drying oil fills the pores of flax like a polymer. But finding high-quality ingredients is quite difficult, so red lead is often replaced with iron, which only accelerates the oxidation of metal components. Some craftsmen get out of the situation by using silicone-based automotive sealants.

- The complexity of laying linen thread on the thread. What is so easy for experienced plumbers can cause a lot of difficulties for a non-specialist. It is unlikely that it will be possible to wind flax correctly on the connection the first time, and any error during this operation will lead to the fact that the seal will not last very long.

- Len does not tolerate changing working conditions very well. Therefore, in heating systems, its strands will collapse much faster. Also, this type of seal does not respond well to aggressive environments.

- The high hygroscopicity of the material leads to its swelling, due to which insufficiently strong joints can simply burst. For example, it is not recommended to use flax when sealing aluminum radiators.

Sealing with FUM tape or plumbing thread

Due to the ease of use, these materials have gained high popularity. To seal most threaded connections in an apartment, it is enough to wrap the number of turns of tape on the pipe indicated in the instructions and tighten with a wrench. At the same time, special care is not required when laying, on the contrary, many manufacturers recommend winding a little obliquely. The connection with such a seal can be easily disassembled if necessary.

At the same time, the fum tape does not tolerate vibrations, does not cling well to fine threads, and can be damaged by rough cutting. It is not recommended to seal large diameter pipes with it.

Use of sealants

The most optimal method at the moment is the use of various sealants. They provide not only complete isolation of the system from leaks, but also protect metal parts from corrosion.

Sealants are very convenient during installation and allow, if necessary, to disassemble the threaded connection without significant effort and damage.

There are the following types of sealants.

Non-hardening sealants

Available in the form of thick and viscous pastes, consisting of polymers and synthetic resins. This consistency allows them to provide high-quality sealing of joints, to calmly endure vibration loads. Such sealants are often used in combination with other sealants.

Important! Non-hardening sealants cannot be used in high pressure systems - the composition will simply squeeze out of the thread. They also do not tolerate the impact of aggressive materials.

Hardening compounds

Produced on the basis of solvents. Such substances are also known as adhesive-sealant, as they provide not only tightness, but also reliable fixation of the connection.

How long does this material dry? Usually, the manufacturer indicates the hardening time on the packaging, it can be from several minutes to several hours. It should be remembered that at low temperatures, the crystallization time increases significantly.

Their main disadvantage is the presence of shrinkage during solidification, which leads to the need for additional tightening of the fittings. Another unpleasant feature is the impossibility of dismantling the connection without destroying the sealing layer. After disassembly, it will have to be removed and reapplied.

Anaerobic sealants

The most convenient and reliable sealants at the moment. Their liquid structure allows them to easily penetrate the narrowest gaps. In air, such a composition does not change its properties, but when it enters a threaded joint, upon contact with metal and in the absence of air, it sharply changes its properties and crystallizes. It turns out a durable plastic that reliably seals the threaded gap. At the same time, excess glue squeezed out after assembling the joint can be used to process the next pipe, and the sealant that has got inside can be easily washed off with water.

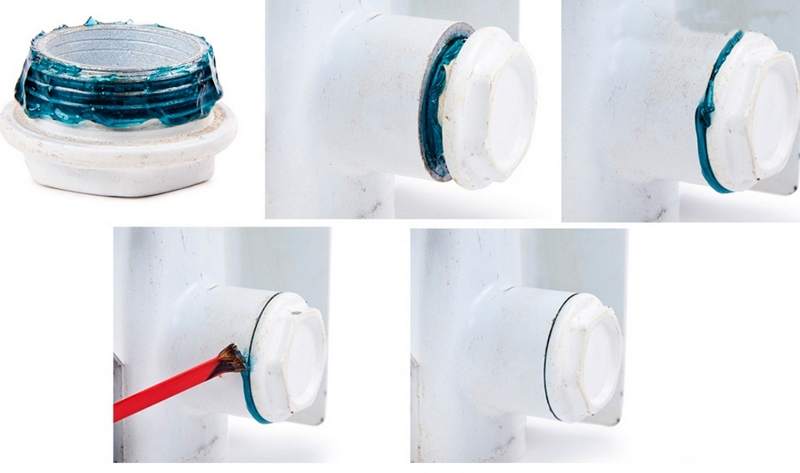

Using anaerobic sealants is very simple:

- All surfaces of the threaded connection must be cleaned and degreased. It is enough to wipe new parts with a solvent, old ones - to process with a special metal brush.

- The solution is applied to several threads; for convenience, you can use a regular brush.

- The connection is tightened manually, without the use of keys.

- Excess sealant that has come out from the outside is removed with a napkin. You can use it to seal another connection.

- The hardening of the material will take a couple of hours, after which you can safely use the threaded connection. The manufacturer's recommendations will help determine the crystallization time more accurately. Do not forget that it increases significantly at low temperatures.