Recently, in suburban summer cottages, you can often see such a design as a compact and convenient prefabricated greenhouse made of polypropylene pipes. The huge popularity of such structures among amateur gardeners is primarily due to ease of use, reliability and low price. Such a lightweight design will cost no more than 2 thousand rubles, and it will last a long time. For comparison: the cheapest ready-made prefabricated factory greenhouse costs at least 15,000 rubles from dealers.

How to build a greenhouse from polypropylene pipes: preparation of materials

You can assemble a classic arched PVC greenhouse with your own hands in just a couple of days. The materials for its manufacture will need the following:

- PVC pipes intended for hot water supply are thick-walled (at least 4.2 mm). It is better to take a thicker option (with an inner diameter of at least 16.6 mm).

- Reinforcing bars 75 cm long and 10-12 mm in diameter.

- Edged board 150*30 mm.

- Thin rails for attaching the film to the timber.

- Film for hotbeds reinforced or cellular polycarbonate.

- Bar 50*50 mm.

- Nails and screws.

You will also need to buy a couple of pipes of a larger diameter than those prepared for the frame pipes. They will be needed for the manufacture of plastic latches for the film and door hinges.

A greenhouse is assembled from polypropylene pipes using the following tools:

- Hammer and drill.

- Garden drill or sledgehammer.

- Sharp paint knife.

Choosing a plot for a greenhouse

Of course, this structure should be mounted in a sunny, well-ventilated place. You should not put a greenhouse where too much snow accumulates in winter. If the load is too large, the film may not withstand and tear. It is not necessary to comply with this condition only when the structure is planned to be dismantled for the winter. The area under the greenhouse should be as flat as possible. The earth on it should be slightly tamped.

Base assembly

So, let's start to understand how a greenhouse is assembled from a polypropylene pipe with our own hands. Before starting the installation of its frame, a careful marking of the selected area should be made. The corners of the wooden frame from the board must be absolutely straight. You can mark the ground, for example, using the Egyptian triangle or “two curves” method.

The lower wooden framing is assembled using self-tapping screws or nails. After installation, a reinforcing bar should be inserted into each of its corners from the inside. This will avoid distortions in the process of assembling the frame.

After the strapping is ready, you can proceed with the installation of the most important element of the base - reinforcing fastening rods. The pits under them are easiest to make with a garden drill, since they must be deep enough (at least half a meter). You can also try to hammer the rods with a regular sledgehammer or hammer. However, in this case it is more difficult to achieve absolute verticality.

The rods should protrude about 25 cm above the soil surface. They should be placed on both long sides of the future greenhouse in 50 cm increments.

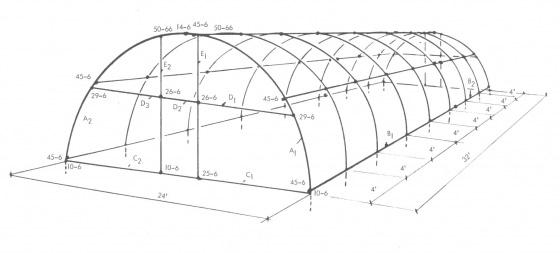

Frame assembly

After the base is ready, proceed to install the "ribs" of the greenhouse. To do this, the pipes are simply put on the rods on both sides. The result is pretty solid arches. At the next stage, polypropylene pipes should be reinforced with transverse stiffeners. They are also made from PVC pipes. You can fix the crossbars both on the wire and on the plastic tees. In the latter case, the fittings are put on the arched ribs in advance. They can be soldered to the pipes, but it is better to use self-tapping screws for fastening. In this case, the greenhouse will be collapsible.

![]()

The number of transverse stiffeners depends on the size of the structure. However, even for a bulk greenhouse, more than two or three on each side are rarely used. The only obligatory element of such a PVC design is the upper central transverse plastic “horse”. Without this element, the film will sag after the first rain.

What does a greenhouse made of polypropylene pipes look like? Drawings and photos of such structures can be seen in the article.

ends

These elements are assembled from a bar, previously carefully treated with antiseptic anti-rotten compounds. The film is attached to the beam by means of self-tapping screws through the rails. If desired, the tree can be replaced with the same PVC pipes. In this case, the segments of the required length are simply installed on the ends vertically along the edges of the future door. To the first arch, they can also be fixed on tees. At the bottom, fixation is made on reinforcing bars.

To the resulting plastic "jambs" you will need to attach a door assembled from segments. To do this, short pieces of PVC pipes of a larger diameter are soldered to one of the vertical racks from above and below. A door is placed on them.

Film wrapping

A home-made greenhouse made of polypropylene pipes is sheathed, usually reinforced with polyethylene. Do not use ordinary film for this purpose. Especially for a long time such a sheathing will not last. It costs a little more and lasts much longer.

Cutting the skin is best done directly in the greenhouse. In this way, inaccuracies can be avoided. The length of the stripes should be slightly longer than the length of the edges of the "arches". The fact is that the film at the final stage is usually tucked under the strapping. You can also fix it to the tree through the slats. It is fixed to the arched "ribs" with special plastic clips. The latter are made from short pieces of pipe with a larger diameter. These tubes are simply cut, breaking along the length on one side with a narrow strip. The result is a comfortable elastic clamp.

After the film is securely fixed, the assembly of the PVC greenhouse can be considered complete.

Other designs

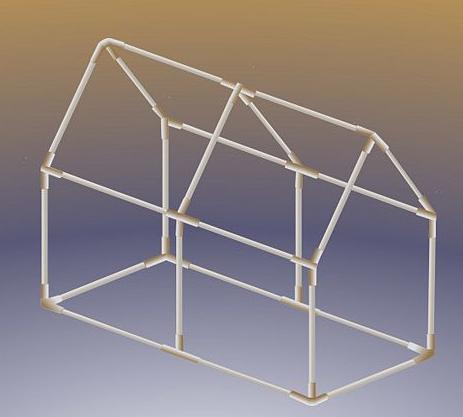

Of course, greenhouses made of polypropylene pipes can have not only the classic arched shape. It is very easy to build, for example, a house structure from this material. Its assembly procedure consists of the following steps:

- The strapping from the board and the fixing rods are mounted in the same way as in the first case.

- Next, vertical racks of pipes are installed on the reinforcement.

- Then plastic "rafters" are mounted from identical segments.

- They are connected to the ridge element by means of tees of the appropriate shape. With racks "rafters" are connected with fittings. At the top, each form should be reinforced with a horizontal cross member from a segment of the turba.

- At the next stage, transverse stiffeners are mounted (also on tees previously put on vertical racks).

Use of polycarbonate

Greenhouses made of polypropylene pipes are sheathed not only with a film. It is quite acceptable to replace it with a fairly flexible and lightweight material. It will last longer than the film, but it will also cost more. It should be attached to the pipes on roofing screws with thermal washers. Unlike reinforced film, polycarbonate is able to expand and contract with changes in air temperature. Therefore, when using rigid fasteners, such a skin will quickly become unusable. The diameter of the holes for ordinary self-tapping screws in the sheets should be slightly larger than their rods. In this case, a gap of approximately 1 mm should be left between the fastener head and the sheathing sheet.

Polycarbonate is a material, of course, very reliable and durable. However, more often they are sheathed with greenhouses on a frame made of a profile or corner. For plastic, they usually still use a budget film.

How to care for a PVC greenhouse

As already mentioned, it is better to make a plastic structure collapsible - on self-tapping screws. In this case, in the fall, after harvesting, it can simply be removed to the garage or hozblok. If the greenhouse remains to winter in the garden, snow will have to be periodically swept away from it. Otherwise, the film may not withstand and tear. Polycarbonate carries much greater loads. But you still have to remove a layer of snow from it. Otherwise, the skin will be covered with a thin crust of ice during the thaw. Polycarbonate is absolutely resistant to scratches.

In the spring, the walls of the greenhouse with any kind of sheathing will need to be thoroughly washed with soapy water using a soft cloth.

As you can see, creating a greenhouse from pipes with your own hands is a very simple procedure. It takes a little time to assemble such a structure. This light construction costs a penny. So to build a neat PVC greenhouse in the garden is quite within the power of everyone.