This tutorial will show you how to make a VERY large table out of a hollow door and PVC pipes and fixtures. Such a table is suitable for workshops, offices, family dining rooms and even for children. I made a dozen of these as office desks. The one you see in the photo was my first creation.

Each such table costs about 2500 rubles.

We could buy ready-made tables for half the price, but these look much more respectable. They can be painted in any color, the surface is perfectly flat and smooth. And the biggest advantage is the size - 91.5 x 203 cm (36 x 80 inches).

A few important points:

1. Hollow filler vs. Solid aggregate A: I chose hollow parts to keep costs down. Since no one was going to use tables for heavy work, there was no need to use super strong materials. If you want to make a durable workbench, then it is better to take a solid door, which will cost an extra 800 rubles. And such doors are much heavier (which is not so bad, the design perfectly withstands such a weight). You can buy a ready-made countertop at Ikea if there is such a store nearby.

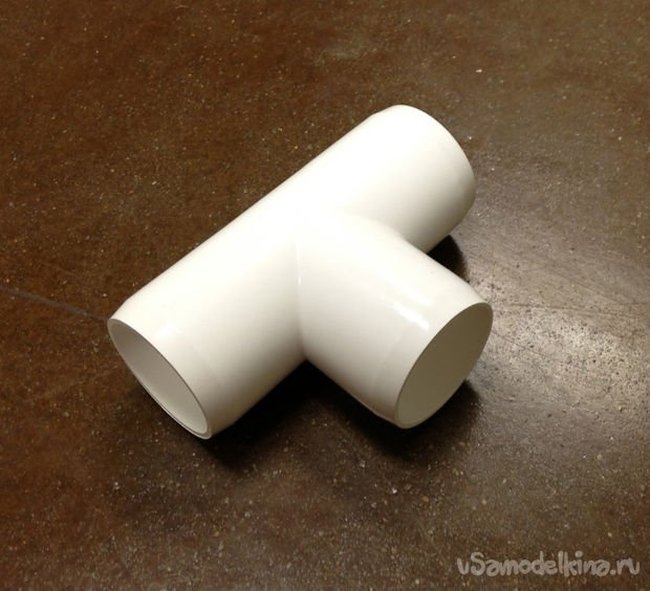

2. Mounts A: All PVC parts were bought by me on the Internet. You will need desktop end caps, 4-way, and regular tee connectors. The total amount for one table is 970 rubles. These costs can be reduced if soldering is used instead of cross and tee joints, but this can have a negative effect on the appearance of the finished table.

3. Pipe A: I used PVC tubing from a regular plumbing store. With a big budget, I would take pipes not for plumbing, but for furniture, a higher class and looking better. They are stronger and more durable, but the economy has won. If we continue to develop PVC furniture, I will use special materials for furniture.

Step 1: Tools

For this table you need to take the usual tools:

1. You will need some kind of pipe cutting tool - a hacksaw, a plastic pipe cutter, or an electric miter saw. The choice is yours!

2. Hammer drill or electric screwdriver for attaching the table legs to the back of the table top.

3. You need a minimum of 15 1.25" - 1.5" threaded screws and self-tapping screws. Screwdrivers are not always needed, but sometimes they are used to strengthen the fastening of plastic cups to the countertop.

4. PVC cement is needed to strengthen all fasteners. All plastic parts will be securely glued together and will not fall apart. You can also use small 1/2" wood screws if cement is not available.

Step 2: Details

I used PVC furniture fittings. This is because I needed 4-way T-joints, foot cups, and flat-top end cups. The remaining elements may be from the plumbing class, but in terms of compatibility and planting depth, the classes are almost the same among themselves.

I ordered all these parts online. It doesn't matter which store, as long as the assortment has all the set you need.

I ordered these parts:

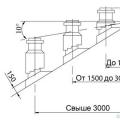

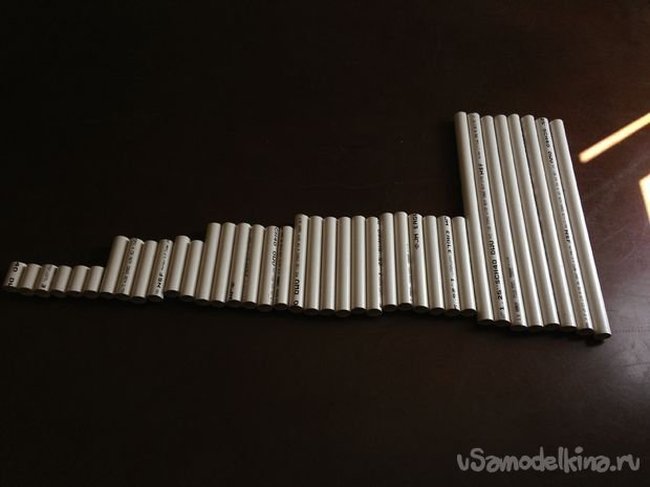

I used plumbing pipe to save on material costs, as furniture pipes can cost a lot more. It took me about 12 m of pipes for one table, I bought 3-meter pipes, which I cut into such segments:

Step 3: Assembly: Side 1

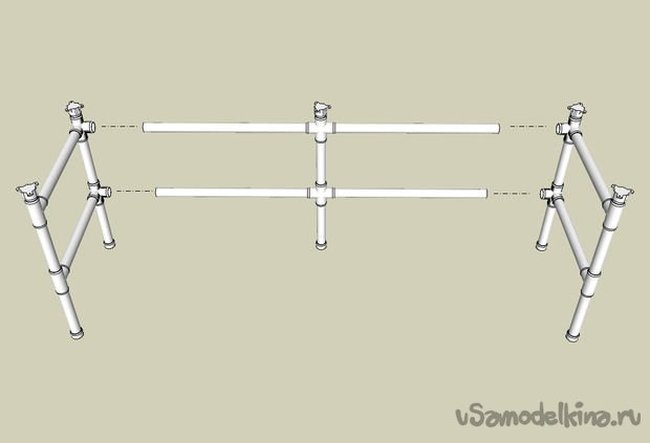

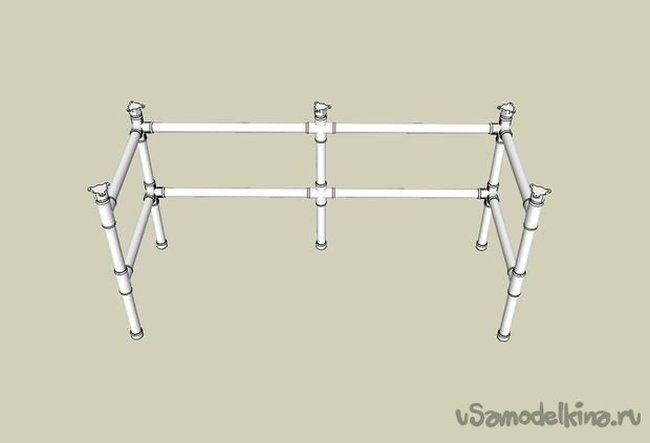

I will clearly show each stage of the assembly in the outline. I used SketchUp. It's better than showing you our dirty work office where we moved in photos.

Let's get started:

Side assembly 1

First you need to assemble one of the two sides of the PVC frame, using the regular and 4-way T-joints, flat plugs and table plugs that are marked in the picture. The fasteners themselves are signed BLACK, dimensions of pipe sections - RED. This will be "SIDE 1", or the left side of the table.

Apply PVC cement only on the inside of the connector, on the stop line. Make sure all parts are inserted into each other as expected, and then press the pipe into the connector and hold for 30 seconds.

NOTE: most people will advise to apply cement to both the connector and the pipe, but personally I have found that this is not necessary.

ANOTHER IMPORTANT THING: If you do not want to use cement as it is harmful indoors, use a screw between the connector and the pipe to seal the fixture.

AND ANOTHER NOTE: I tried to fix the pipes so that all their marks are directed to the back (the rear is where the 4-way T-connectors are). This way they will not be visible from the outside of the table, and do not need to be washed with acetone for a cleaner look. I still didn’t manage to hide all the inscriptions, as you can see from the photo. Learn from my mistakes.

Step 4: Assembly: Side 2

This step exactly repeats the previous one, but the design of “Side 2” mirrors “Side 1”. 4 way tee connectors face the opposite direction when facing back.

In this drawing, the dimensions of the pipes are also indicated RED, and connectors BLACK.

Step 5: Assembly: BACK

It's time to assemble the "Back" of the table, which is even simpler than the previous ones. You will need a desktop end cap, a flat end cap, and two cross connectors (we haven't used those yet). Connect long pieces of pipe (75 cm or 30 inches) with them so that the shape is something like a telephone pole.

To assemble the central “pillar”, lay everything on the floor so that all the long pipes are parallel to each other. This will make it easier and more accurate.

Step 6: Assembly: Combining Fragments

Now you need to collect all the PVC fragments into one design.

Insert the pipe ends from the “back side” into the appropriate SIDE 1 and SIDE 2 connectors. The end should look like the drawing. Again, I recommend that you dry everything first, and then glue it on the cement.

Once the assembly is dry, separate the pieces and apply PVC cement to the SIDE 1 connectors and insert the back tubes into the 4-way T-pieces of SIDE 1. Quickly make sure everything fits properly, squeeze for 30 seconds.

Here you have finished the frame! Almost everything!

Step 7: Assembly: Tabletop

Disadvantages of a hollow door:

Hollow doors consist of an outer frame and various horizontal bars. Between them, the space is either filled with cardboard, or foam, or nothing at all.

From the outside, we cannot see what is inside the door, so we can only randomly screw in screws to secure the table top to the table cups. It is equally likely to hit the bar or soft cardboard. In those places where there is cardboard, it is better to use a screwdriver to better fasten the structure. Here's how it's done:

1. Lay the hollow door on the floor with the side that will be the front of the table. Then lay the PVC construction on top, upside down, so that the tabletop plugs adjoin the door.

2. Center the entire structure (by eye, of course) so that it is at the same distance from the edges of the door. Then, using a pencil, mark where the plug holes meet the door.

3. Remove the PVC construction from the door and set aside. Use a drill or electric screwdriver to drive a screw into each marked point.

* If the screw goes through easily, you are in the voids of the door. Remove the screw and insert the driver into these holes (you can drill a larger hole if needed)

* If the screw goes tighter, you hit the bar, and here you can do without a screw driver. Remove the screw.

Once you have decided where the screws are and where not, make sure that all the screws are removed from the door and put the PVC structure upside down on the door again, adjusting the position of the plugs to the holes made.

NOTE: All this can be avoided by using a solid massive door. It will be more expensive, but easier.

Finally, insert the screws and tighten, thus securing the table top and legs. Before you is a finished table, though upside down.

Step 8: Finished: Flip and That's It!