First of all, the post is addressed to those who do not want to be “attached” to trips to the service station or to a neighbor who has a pit or a lift. If you fall under both points, then read on, if not, then it’s better to pass by, because you still won’t be able to understand me =) As they say, a well-fed person will never understand a hungry person =)))

I recently passed over a year of driving experience, but I started tinkering with cars no more than six months ago. I had to start somewhere and I decided that it would be more convenient for me to make the option described below from wood.

You can easily adjust the dimensions of the overpass to the dimensions of your car: track, height. You don't have to do everything exactly. I just shared information that made my life very easy in terms of repairing and maintaining my 2004 Ford Focus 1.

The time has come to change the engine oil and I really didn’t want to call the service station again, sign up for a window they had open, and so on and so forth. And I really want to do all this myself, and especially for free =) In addition to this, the time was approaching for the arrival of a good portion of spare parts at the autodoc.

Regarding changing the oil on an incline::

Many people write that the oil is changed only on a horizontal platform. All the oil drains into the pan, right? Drain plug My pan is located closer to the rear bumper, that is, this is the lowest point in the pan relative to how the car sits, right? So if I salt the oil in this position, why should anything remain? Or am I misunderstanding something?

I will pay special attention to those who are especially gifted and narrow-minded/seeing/understanding and everything in this regard: The overpass is suitable for any work when the car needs to be hung so that you can crawl under the bottom and easily remove the protection, so that you can then do everything that is necessary without being in a cramped space. It's not just for changing the oil! With such a height, namely 45 cm, it is very convenient to work under a car. Anyone who hasn't tried it won't understand.

I’ll specifically cite some work that I would never have done myself without the overpass:

No. 1) Replacement of all power supports of the internal combustion engine Ford Focus 1 Zetec 1.8 (Ford 1 094 591, Ford 1 133 019, Lemforder 3108501) -

No. 2) Replacement of coolant with Lukoil G12 Red + Replacement of thermostat -

No. 3) Heater 220V Start-Turbo ("station wagon" No. 2) 2.0 kV + flushing the coolant system LAVR (2in1) -

No. 4) Major maintenance for 186,000 km (oil, filters, sensors, etc.) -

Try to do this only with a rolling jack. Yes, you will die sooner and this will really be the case when “let’s quickly finish all this... crap.” When using it, it is very inconvenient to unscrew the protection, because you can easily crawl up from the side of the jack, but on the opposite side it becomes very cramped.

Another very important aspect is safety. On an overpass, a car will never make a fool of you. In the case of a rolling jack, the presence of a safety stand is mandatory. Otherwise, anything can happen. No one is immune from accidental failure of the jack.

There is a two-tonne rolling jack, but I haven’t found a great use for it yet. Stands to the side.

There is no pit yet, much less a lift. The car is parked in the yard and crawling under it once again is a thankless task, since you need to remove the protection and lie, even if on cardboard, but still on the ground. It turns out that you need to put a jack on one side, substitute all sorts of stumps, and in any case the car is “on its feet,” let’s call it that. In general, it’s still a perversion.

Then I started looking at a rolling jack, at least a 3-ton jack, and in addition to it a couple of safety stands. Provided that I took it through my own company, it would come out to about 7,000 rubles. I even made a request for an invoice from the 220 Volt store.

On the same day, wandering around the Internet, I accidentally found the phrase “do-it-yourself mini-overpass.” I looked through all the options and decided that I could go with the “wooden” version)) And then I got excited, this is it, this is what I want to get in the end.

The option of making an overpass from metal structures was also not for me; I don’t have a welding machine, and I didn’t want to strain a welder I knew.

Therefore, only the “wooden” option remained.

I remembered about the garage that my mother has, it is conditionally abandoned, since it is used for storing all sorts of things, but not for car repairs, and getting to it is not so easy: the swing doors of the garage were wedged due to frost heaving of the soil, the area was covered in snow at 60-70 cm thick

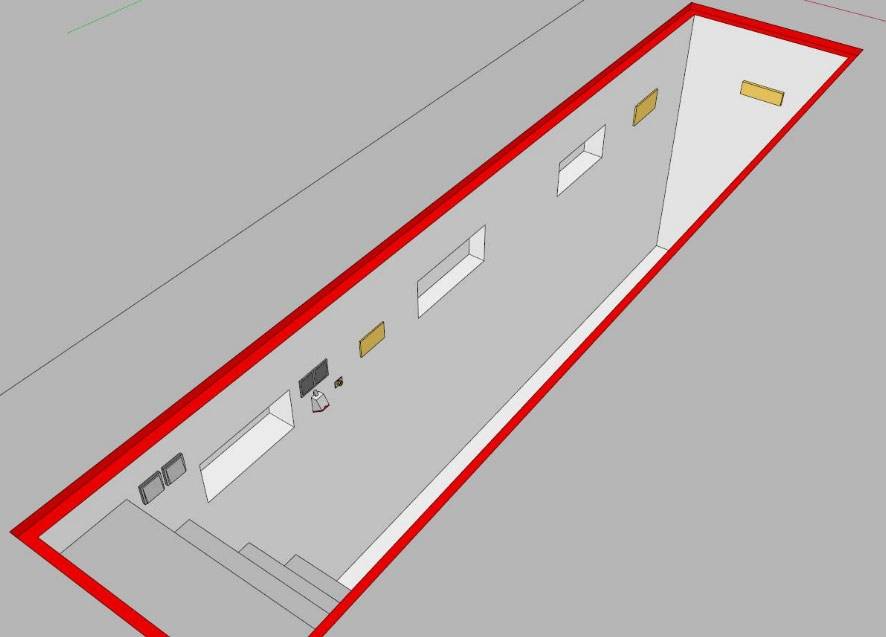

Stage 1: I sat at my laptop and quickly sketched out a design for an overpass in order to calculate the costs of materials. As a result, there were 8 boards measuring 50x150x6000 mm. The ideal board option would be 300 mm wide, but I couldn’t find this type of timber in Kemerovo, so I had to take an option from boards 150 mm wide. The only remark is that for some reason I took the gauge not 1480 for my Fedor, but 1580 mm and apparently was thinking about something at that moment, although I clearly looked at the repair manual and operation behind the wheel. Therefore, position 2 (emphasis) on the drawings, figure out how to correct it =)

Be sure to pay attention: Check the pitch of the shelves (height and length) of the overpass and their height to ensure that the front bumper of the car does not rest against the end boards. Measure everything first according to the fact, and draw a car on a one-to-one scale at the bottom point of the overpass, and then at the top. From these two points, throw an imaginary line and make sure that it does not shuffle along the boards. Otherwise you’ll get a funny picture: you’ll collect everything, start driving in and bend the bumper, and leave me at the end.

Almost every motorist needs an inspection hole. With its help, you can perform a routine inspection of the car and its partial repair. Such a structure is especially important if there are no service stations nearby.

Why is the structure needed?

As already mentioned, if you have a car, then there may be certain problems with the mechanisms. Not all breakdowns can be fixed right in the garage. Sometimes you have to climb under the car. Naturally, doing repairs lying down is not very convenient. This is precisely why the overpass was invented.

It is not difficult to make such a structure with your own hands. You just need to decide on the design and collect all the necessary materials. It should be noted that to build the structure you can use everything that is on your farm. For example, an overpass for car repairs can be made of metal stairs (above-ground version), bricks, or simply dug in the form of a hole (underground version).

What tools might you need?

It is quite simple to construct such a structure. You must first draw a diagram on paper, calculate its dimensions, and also select the necessary tool:

- Welding (if a metal version is built).

- Grinder (for cutting materials).

- Shovel (if you want to make a hole or fix overhead posts).

- Brick and sleepers.

- Cement (to prevent the product from “driving”, it should be fixed with concrete mortar).

From this list you choose what you will need depending on the materials.

How to make the simplest design option?

It is a structure on which a car can drive only with its rear wheels or only with its front wheels. This type of overpass for a car consists of identical structures that can be made of metal or wood. Please note that the width of such products should not be less than 40 cm. Otherwise, they may be unstable or too narrow.

This structure can be welded from corners. In this case, the cross-section of the elements is about 2.5 cm. To prevent the car from sliding off the overpass, limiters must be fixed on the racks. Their height is at least 7 cm. After all welding work is completed, sharp corners must be removed using a grinder. In order for the product to last as long as possible, it must be coated with a special anti-corrosion compound or painted. Please note that one element of such a structure will have quite a lot of weight.

How to make a structure from stairs?

A similar overpass can also be done quite quickly with your own hands. It is a more advanced option than the previous one. To work, you will need two metal ladders at least 3 meters long, a welding machine and corners.

First you need to treat all components with an anti-corrosion compound. Next, you need to weld 4 vertical supports to the edges of the stairs, on which they will stand (like benches). Their length should be sufficient so that it can be partially dug into the ground. Naturally, in this case it is better to choose corners or pipes. In any case, these elements must be strong enough to support the weight of the car.

After the main structure is assembled, it is necessary to fix it in the garage. Place the future overpass so that it is convenient for you to drive onto it. The posts in the ground must be fixed with concrete mortar. In order for the car to drive onto the structure, 4 more corners (on both sides) need to be welded to the stairs at an angle. It is better to unite them together with crossbars.

Features of the inspection pit arrangement

The construction of an overpass of this type is the most common. However, it is possible under one condition: you have a lot of free space. Such an inspection hole must have a depth of at least 1 meter. This parameter depends on the height of the person who will be repairing or inspecting the car. To prevent the earth from crumbling inside, it is better to cover the walls of the structure with boards. To make it convenient to go down into the hole, you need to either dig steps or install a ladder. Please note that the steps should be equipped with anti-slip pads.

Please note that the edges of such an overpass should be slightly above ground level. The length of the pit must correspond to the size of the machine. In this case, after driving in, the car should not block the descent stairs. As for the width of the ditch, it is about 1 meter. Safety flanges must be added to this distance.

As you can see, a do-it-yourself overpass can be built quite quickly. You just need to draw a diagram in advance and select materials.

Arrangement of the overpass

Naturally, workplace must be suitably equipped. For example, there should be a workbench nearby with all necessary tools. Everything you need for repairs should be within arm's reach.

You will also need to arrange good lighting. It is better to use LED or fluorescent lamps. Inside the inspection pit, you can make additional shelves on which tools will be placed. Please note that they must be secured as well as possible, and at a level so that if any products fall, they cannot harm you.

The inside of the pit can be lined with bricks. It's better to build a foundation. The surface on which the car will stand must also be secured as much as possible. It is better to install it on pipes dug deep into the ground.

If you need a trestle, you can make it yourself in just one day.

Hi all.

Hi all.

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

","contentType":"text/html"),"proposedBody":("source":"

Hi all.

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

Hi all.

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

","contentType":"text/html"),"authorId":"106393900","slug":"estakady-dlya-remonta-avtomobiley","canEdit":false,"canComment":false,"isBanned" :false,"canPublish":false,"viewType":"minor","isDraft":false,"isOnModeration":false,"isSubscriber":false,"commentsCount":24,"modificationDate":"Tue Nov 22 2016 19:10:22 GMT+0000 (UTC)","isAutoPreview":true,"tags":[("displayName":"question","slug":"questions","url":"/blog/narod -karta??tag=vopros")],"isModerator":false,"url":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley","urlTemplate":"/blog/narod-karta/ %slug%","fullBlogUrl":"https://yandex.ru/blog/narod-karta","addCommentUrl":"/blog/createComment/narod-karta/estakady-dlya-remonta-avtomobiley","updateCommentUrl ":"/blog/updateComment/narod-karta/estakady-dlya-remonta-avtomobiley","addCommentWithCaptcha":"/blog/createWithCaptcha/narod-karta/estakady-dlya-remonta-avtomobiley","changeCaptchaUrl":"/ blog/api/captcha/new","putImageUrl":"/blog/image/put","urlBlog":"/blog/narod-karta","urlEditPost":"/blog/583311ccce6a0e001fbf4e99/edit","urlSlug ":"/blog/post/generateSlug","urlPublishPost":"/blog/583311ccce6a0e001fbf4e99/publish","urlUnpublishPost":"/blog/583311ccce6a0e001fbf4e99/unpublish","urlRemovePost":"/blog/583311ccce6a0 e001fbf4e99/removePost", "urlDraft":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley/draft","urlDraftTemplate":"/blog/narod-karta/%slug%/draft","urlRemoveDraft":"/blog/ 583311ccce6a0e001fbf4e99/removeDraft","urlTagSuggest":"/blog/api/suggest/narod-karta","urlAfterDelete":"/blog/narod-karta","isAuthor":false,"subscribeUrl":"/blog/api /subscribe/583311ccce6a0e001fbf4e99","unsubscribeUrl":"/blog/api/unsubscribe/583311ccce6a0e001fbf4e99","urlEditPostPage":"/blog/narod-karta/583311ccce6a0e001fbf4e99/edit","urlFor Translate":"/blog/post/translate" ,"urlLoadTranslate":"/blog/post/loadTranslate","urlTranslationStatus":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley/translationStatus","urlRelatedArticles":"/blog/api/relatedArticles/narod -karta/estakady-dlya-remonta-avtomobiley","ampUrl":"https://blog.yandex.net/amp/ru/narod-karta/estakady-dlya-remonta-avtomobiley","author":(" id":"106393900","uid":("value":"106393900","lite":false,"hosted":false),"aliases":(),"login":"Unknownboy1993","display_name ":("name":"Vova Sh..yandex.ru/get/106393900/islands-middle","isYandexStaff":false),"originalModificationDate":"2016-11-22T16:10:22.084Z"," socialImage":("orig":("fullPath":"http://avatars.yandex.net/get-yablog/4611686018427432610/normal")))))">

If you own your own car and garage, but prefer to at least occasionally look under your car yourself, then the following is for you. Typically, inexperienced drivers prefer to carry out inspections only at a service station and give their hard-earned money to “specialists”, but even carrying out minor work on changing oil, consumables, monitoring the condition of the units and mechanisms of your car can save your budget. A do-it-yourself overpass made in a garage is the best way out of this situation.

Let's look at the statistics of a survey on the topic of whether it is difficult to make an overpass in a garage with your own hands. 66% of respondents answered that it is quite simple; 14% believe that it is simple, but with minor problems; 16% said it is not easy and will require skills in this area; for 4% this is a very difficult task.

Depending on the size of the garage and the model of the car, you can choose an overpass option that will meet your needs.

Overpasses can be divided into 2 types:

- for full vehicle entry;

- for partial lifting of the vehicle.

The first type will provide more comfortable working conditions for car maintenance than the second.

Overpass options for full vehicle entry

Such a statement will be correct from the point of view of the meaning of this word. But the function of the pit is the same as that of the overpass - to provide access to the bottom of the car.

Such a statement will be correct from the point of view of the meaning of this word. But the function of the pit is the same as that of the overpass - to provide access to the bottom of the car.

The advantage of the pit is that it will not take up useful space in the garage.

If the level groundwater in the area where your garage is located, it is high, then it is not advisable to consider the issue of an inspection hole.

Otherwise, you will have to make an additional drainage system (which is very troublesome and expensive), and the bottom of your car will be subject to constant corrosion due to moisture that will collect in the hole.

As a result, you will have to fill it up and consider other options.

Brick overpass

This option is suitable for those who have a garage in a rural area or in the country. This design is carried out by simply laying bricks on cement mortar - along the width of the distance between the wheels of the car in the form of a trapezoid.

The disadvantages of this type of overpass are obvious: a site is required for its construction; brick may deteriorate over time; If you need to vacate the site, dismantling the structure will require significant effort and time from you.

Overpass made of railway sleepers

This overpass is assembled from several railway sleepers, like a children's construction set.

You can lay out 2 bases by stacking sleepers one on top of the other in the form of a slide. Lay tracks across for driving.

To prevent the structure from moving apart during the repair of your car, it must be secured with staples. The disadvantages of this overpass are obvious.

Firstly, not everyone has sleepers in stock. Secondly, sleepers are very heavy; one person will not be able to assemble and disassemble such a structure. Thirdly, after completing automotive repair work, you need a lot of space to store sleepers.

Of course, if you are building this structure in a garden plot, you can leave them in the open air. Sleepers are usually impregnated with creosote, which protects the wood from rotting.

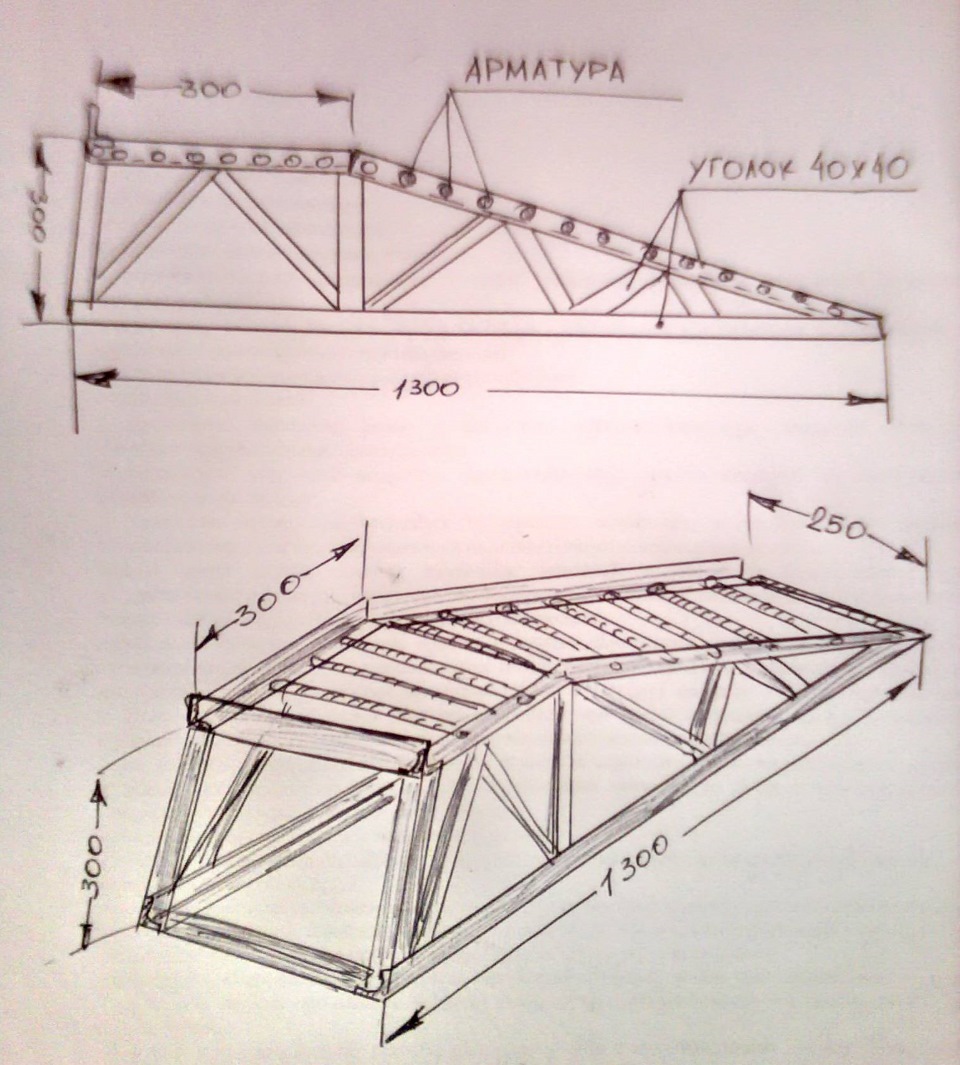

Metal version

If the previous options are possible if there is a plot of land, then a metal overpass can be considered as universal - it can also be used in urban environments.

To make it you will need the following tools and materials:

- rolled metal;

- welding machine;

- fittings;

- grinder with cutting wheels;

- bolts with nuts;

- metal paint.

If desired, you can make the overpass collapsible. This will save space by quickly assembling it when necessary.

Its design is quite simple. It is necessary to assemble 4 base posts with a height of approximately 50 cm. To ensure stability, it is better to assemble the sides in the shape of a trapezoid and connect them with crossbars of the same length.

A 63 corner (5 mm thick) is suitable for this. To make bridges, you can use 40 angles (4 mm thick) and reinforcement (12 mm is suitable).

The bridges are a metal ladder. It will be necessary to make 2 bridges for driving in and 2 bridges on which the car will stand during repairs. You can calculate the minimum length of the latter yourself by measuring the distance between the centers of the wheels of your car and adding a small allowance.

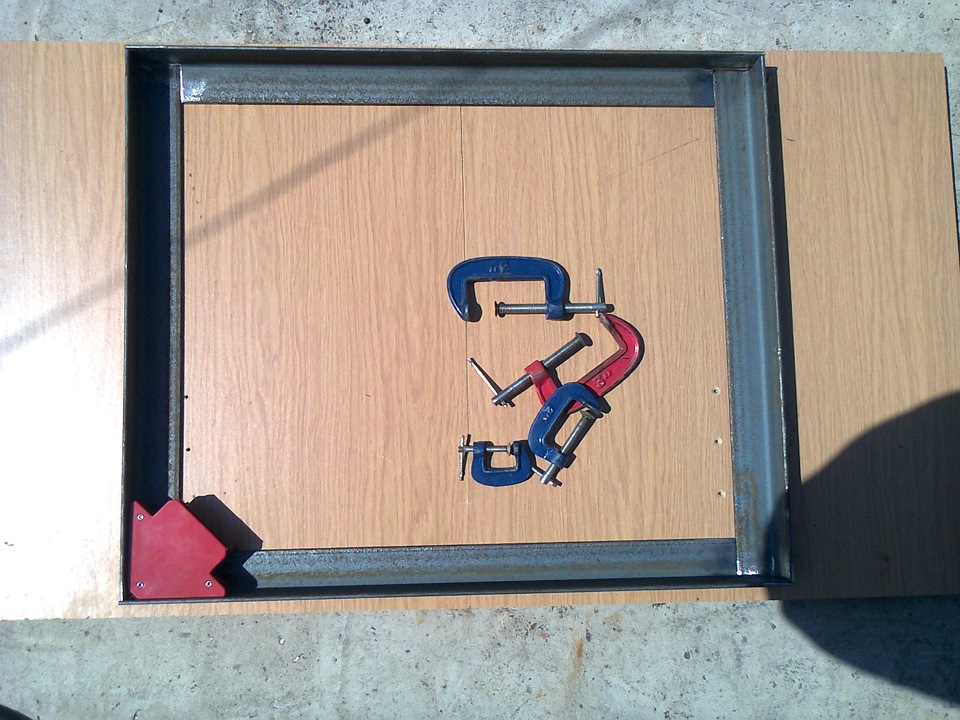

After the individual elements are ready, they need to be bolted together. In order to provide additional rigidity to the entire structure, you can combine the racks with each other. The bolted connection will allow you to quickly assemble or disassemble the entire structure.

Construction of an overpass for a garage

If there is a complete shortage of space, a way out of the situation can be found in the manufacture of mini-overpasses. They refer to overpasses for partial lifting of a car. Of course, working in this case will be less comfortable than with the options discussed above, but much more convenient than under a jacked-up car.

Several options for mini-overpasses

The most basic version of a mini-overpass can be made of wood.

To do this, you will need a board (you can take it 50 mm thick), which is wider than the wheels, and a square wooden strip (for example, 100x100 mm). The height of the cross section will determine how high the car can rise. With the parameters of wooden products recommended above, the lifting height will be 150 mm.

The structure is assembled as follows.

- A block is attached to the top of the back of the board, which will serve as a limiting wheel travel. 2 square-section slats are attached to the bottom: one is slightly further from the middle, the second is on the edge of the board. The structure is ready.

- You need at least 2 such devices (or 4 if you need to lift the entire car off the ground). This mini-overpass works very simply. When you place the structure under the wheel of your car, it rests on the ground at 2 points: the front edge of the board and a block that is secured near the middle.

- Once the car's wheels hit the board and the center of gravity moves closer to the rear edge of the board, the front edge will rise and the rear will lower. Since the supports were made of a block with the same cross-section, the board will take a horizontal position.

- In this case, the length of the board should be such as to prevent it from hitting the bottom of your car. All that remains is to secure the wheels that remain on the ground with stops and blocks. As you can see, such a flyover is very easy to make with your own hands. You can make a mini-overpass from metal. Its design will resemble the metal overpass discussed above, only in a smaller version. It also consists of supports on which bridges are attached.

- It is advisable to weld limiters along the edges of the bridges. This will protect your car from slipping.

- One bridge is located at an angle from the ground for entry, the other is horizontal (if you look at the structure from the side, the outline will be a trapezoid). You can focus on the following dimensions: base length – 80 cm; the length for the drive is approximately 45 cm, the width of the bridges is about 40 cm. The entire structure can be assembled from a 25 mm corner (less than that is not recommended). The approximate weight of the structure will be 20-30 kg. A travel limiter for the wheel must be welded at the rear.

More complex, but effective option mini-overpasses can be made according to the swing-rocking principle. To assemble it you will need welding work. It will be necessary to make 2 frames in the shape of an isosceles triangle. The width of the frames is selected depending on the width of the wheels of your car, and the length of the bridge is selected depending on the length of the car.

To ensure structural rigidity, the frames must be fastened together. To ensure stability of the structure, it is necessary to use spacer stands under the side that will be above the ground. It should be taken into account that for greater stability the center of gravity of the car should be closer to the apex of the isosceles triangle.

When working on overpasses, you should always remember to follow safety measures. The car must be put on the hand brake and the wheels must be secured with chocks.

Let's summarize. You have considered various options and approaches on how you can make an overpass with your own hands. Depending on the available space, materials, finances and desires, you can choose any option for your garage.

This can be either a solid structure or a collapsible version of a metal overpass. Perhaps it will be enough for you to make a wooden mini-overpass. In any case, the choice will be yours.

The overpass is an indispensable tool for inspection and repair passenger car. A small mini-structure is made at home with your own hands. It is important to observe all dimensions and focus on the dimensions of your car.

The need to install a mini-overpass. Device

A modern car is a technically complex device that requires periodic Maintenance, replacement of components and consumables, minor repairs. Many inexperienced motorists prefer to carry out a routine inspection of the car exclusively at a service station and pay out of pocket even for an oil change.

More experienced drivers do most of the work themselves. To do this, a homemade overpass is often installed in the garage - a structure with which you can examine the bottom of the car.

There are two types of overpasses:

To a first approximation, the functions of the overpass are similar to the inspection pit. It provides access to the underside of the car. However, when high level Given the occurrence of groundwater at the site where the garage is being built, it is not advisable to equip an inspection hole: it will constantly be filled with water, which will require additional equipment drainage system, and corrosion will appear on the metal parts of the car due to increased moisture.

A full-size overpass is a monolithic structure that can be found in auto repair shops and along busy highways. Its installation requires a lot of space - the length of the product is about six meters above the ground plus the driveway. The construction of such an option in your own private garage is justified if the building is designed for two parking spaces, one of which is empty.

A mini-overpass is a small portable structure designed for partial collision with a car. It is based on two independent parts that are not connected to each other. The car drives onto the prepared platform with its rear or front wheels, rises slightly above the floor or ground and allows the car owner to carry out an initial inspection or cosmetic repairs.

The advantage of a mini-overpass is the ability to use it in limited space. After work it can be put aside. The main disadvantages of the design are as follows:

- To enter the platform, pinpoint precision is required. Otherwise, the structure may overturn or the vehicle may be damaged.

- Structural elements are installed in places where there is no possibility that they will diverge in different directions from the slightest push of the wheels.

General requirements

When manufacturing a standard overpass, a number of requirements must be met. This will help ensure convenient and safe operation of the vehicle.

- The height of the full-size repair structure is about a meter. This allows you to easily climb under the car, provide a sufficient influx of natural light to inspect the chassis, and carry out the necessary manipulations with spare parts and tools. The height of the mini-overpass with partial access is about half a meter: it does not involve detailed disassembly of the car.

- The width of the structure directly depends on the type and dimensions of the vehicle. You should not display the size down to the millimeter; when calculating the design, you need to make small allowances. The car must drive onto the platform without hindrance.

- Mini-overpasses are used for inspection and repair of passenger cars. For a stationary structure, an additional margin of safety is provided. Thanks to this, the product does not deform over time. You can also roll fairly heavy vehicles onto it.

Material selection

There are many ways to make a do-it-yourself overpass or mini overpass for car repairs.

Brick construction

A brick overpass is a stationary structure, which is more often used in rural areas or outside the city. Construction is carried out using the bricklaying method using cement mortar. The width of the structure corresponds to the distance between the wheels of the car.

This method has a number of disadvantages:

- It is necessary to allocate a plot of land for development. If the overpass subsequently needs to be removed, its dismantling will require considerable effort and time.

- After some time, under the influence of overloads, the brickwork may collapse, which may require its dismantling.

Overpass made of sleepers

The structure is based on several railway sleepers. The sleepers laid one on top of the other in a “slide” style form two bases. Tracks are laid across to ensure access. To prevent the sleeper trestle from moving apart during operation, it is carefully secured with brackets.

This design also has certain disadvantages.

- Sleepers are not so common in everyday life, and not every car owner has a few extra ones.

- It is impossible to install and disassemble such an installation alone. The sleepers are too heavy.

- Storage of railroad ties requires space.

The use of an overpass made of railway sleepers is justified in a summer cottage or garden plot, when the structure is left outdoors all year round. To protect against rotting, the product is impregnated with creosote.

Made of metal

Most often, the overpass is made of metal and wooden boards. Advantages of a metal overpass:

- Mobility. If desired, the structure can be made collapsible and assembled only before starting repairs. This saves space.

- Simplicity of design. You can assemble a metal overpass with your own hands using a minimum of tools.

- Durability. With proper care and timely inspection, a metal trestle can last about ten years or more.

There are also some disadvantages. The metal is initially susceptible to corrosion, so before work the material must be treated with special impregnations.

Among the main advantages of a wooden trestle are the ease of assembly and low cost of materials. It is easy to install and, if necessary, can be quickly dismantled and removed. You do not need complex specialized equipment; ordinary carpentry tools that are found in every home are sufficient. Among the disadvantages of wooden structures are low durability and poor resistance to rot and insects. These problems can be partially solved by treating with antiseptics, fire retardants and insecticides.

Tools and materials

Independent production of a wooden or metal overpass requires the availability of certain materials and tools. There is no need to purchase complex specialized equipment; it is enough to purchase household power tools, which are sold in every store.

What is needed to build a metal overpass

To make a regular metal overpass, you will need the following materials and tools:

- Rolled metal.

- Welding machine with a set of electrodes.

- Grinder equipped with several cutting wheels.

- Pieces of reinforcement.

- Fasteners: bolts, nuts.

- Metal paint for finishing the structure.

Materials and tools for a wooden overpass

To make the simplest portable wooden trestle you will need a minimum of materials and tools:

- Boards 45–50 millimeters thick. If thinner boards are used, additional vertical supports are installed in the center of the overpass.

- Two wooden blocks.

- Two pieces of carriage plank.

- Screws (150), nails (300), screwdrivers, hammer, wood saw.

Preparing for work and drawing up a drawing

Before making the overpass, it is necessary to carry out a number of measuring works. The mini-overpass consists of two independent installations. The width of each of them corresponds to a car wheel with a small margin. The gap between installations is equal to the distance between the wheels of the car. At this stage, tools, materials and work site are prepared.

All dimensions are approximate and calculated for each car model

DIY metal structure

If a metal overpass is planned to be used in several places, or is needed only occasionally, the structure can be made in a collapsible version. This will allow you to quickly assemble it as needed within half an hour.

The assembly of a metal overpass occurs as follows:

The finished structure is cleaned with a metal brush, degreased and painted.

The finished design will look something like this

Making a wooden mini-overpass

The simplest wooden overpass is assembled from two pairs of wooden beams with a cross-section of 20–20 cm. The beams are knocked together in pairs and cut at an oblique angle. The improvised overpass is ready.

An improved wooden overpass is assembled from scraps of boards, which are assembled into a wide “pyramid shield”. On one side there is a stepped slope for cars to drive in.

Another version of a mini-overpass is assembled from four 50-mm boards, two blocks, lining and fasteners.

A similar design is used for repairing passenger cars. For heavy transport it is worth installing a stationary overpass.

Video: Assembling a metal structure

Every car owner can make a mini-overpass on his own. It is very important to check the strength of the structure before driving a car onto it and starting repair work.