Range of application lifting cranes very wide. This is industrial and civil construction, warehouses, workshops, shipbuilding - in a word, everything that requires spatial movement of various cargoes. There are a considerable number of types of load-lifting cranes based on the specific purpose of application. In this article we will try to “climb up the crane”, making stops somewhere and taking a closer look at their structure. The main thing is to come down from heaven to earth!

The term " lifting crane" brings together a huge amount of equipment that is different in scope and design. Perhaps it is impossible to give in one article full review everyone possible options, and there is no need for this. Let's leave it to the specialists to understand the highly specialized equipment that most contractors are familiar with. labor activity does not collide. The purpose of this material is to give an idea of the types of load-lifting cranes existing on the market and to describe the differences between the main ones.

So, the fundamental classification of load-lifting cranes can be called their division into bridge, cable and jib type cranes.

Classification of overhead cranes

An overhead crane is a type of lifting crane, where a bridge consisting of span and end beams connected to each other is used as a supporting structure. A rail for moving the cargo trolley is mounted on the span beam, the device of which also includes trolley position limiters. The load-handling device is suspended from this very trolley (or hoist, as an alternative). The latter can be either a regular hook or special devices such as a grab, magnet, gripper, etc.

Most often, this type of lifting cranes can be found at manufacturing enterprises, where they are in demand in repair and installation shops, as well as in industrial warehouses, railway junctions, etc. The construction industry is not what overhead cranes “prefer”. However, there are special modifications, the equipment of which, for example, includes a grab. These structures can also be used in construction.

Single beam overhead crane. So-called lightweight design

A significant part of the bridge crane market belongs to lightweight devices (also called beam cranes). The lifting capacity of this type of crane is limited to 10 tons, and in general, the upper limit of this characteristic for heavy class specimens available on the market reaches no less than 1 thousand tons.

Lightweight types of overhead cranes are predominantly single-girder; moving the hoist along a bridge consisting of two beams is used in heavier models. At the same time, both suspended and support models are widely in demand: in the first case, the bridge is suspended from the lower flanges of the overhead crane runway, in the second, it rests on the crane runway.

A separate group in the classification of bridge-type load-lifting cranes includes the gantry crane. Its device includes two support posts on which the bridge rests.

Types of cable type cranes

This type of load-lifting cranes can be recognized by the method of attaching the trolley. A load-handling mechanism is suspended from it, as in the previous case. But the cart itself moves along the supporting ropes. The movement mechanism of these cranes varies. It can be parallel - that is, both towers move along parallel tracks, or radial - with one stationary tower and another moving along a ring rail.

If you are going to build a bridge, lock or dam, you cannot do without a cable crane. Also, this type of lifting cranes is used in open-pit mining, for moving bulk cargo, at pulp and paper mills, and as a means of transportation across water barriers.

Bird's eye view of cable crane

Jib cranes

This type of lifting cranes has, perhaps, the most variations, including cranes called directly jib cranes, as well as tower, railway, portal, cantilever cranes, etc. What they all have in common is the presence of a lifting mechanism suspended from a trolley that moves along the boom.

In the port you can see not only a ship, but also a crane

The blue carriage is flying and rocking! It's true that it's not blue, but yellow. And not a carriage, but a railway crane

At almost every construction site today you can see a tower crane, which allows you to lift loads to the maximum possible heights. It can be classified as follows: a jib-type crane, equipped with a rotating boom fixed in upper area vertically located tower. The structure of a tower crane includes a cabin, a cargo trolley, a hook suspension, the tower itself, a boom and other auxiliary units. It is worth noting that in most cases, builders use conventional rail-mounted tower cranes.

Construction "giraffe"

A special feature of jib cranes is their placement on a mobile mechanism. The boom is mounted on a rotating device. The truck crane chassis as a base is in high demand due to its mobility. Instances on a caterpillar chassis, in turn, allow the installation of a crane unit with a significantly higher lifting capacity.

What other classifications of lifting cranes are there?

Above, we have already partially touched on the types of load-lifting cranes based on the method of their installation. According to this criterion, the following are distinguished:

- stationary (this type of load-lifting cranes is attached to a fixed base);

- self-lifting (as the structure is being erected, the load-lifting crane can move upward due to its own mechanisms);

- adjustable (the crane is mounted on a device that can be moved, including manually);

- radial (moves relative to one stationary support);

- mobile (there is the possibility of movement while working);

- trailed (the crane device includes a platform attached to the tractor with a chassis on wheels).

Another criterion for dividing lifting cranes is by degree of rotation. The device of load-lifting cranes can be equipped with a rotating mechanism with the technical ability to rotate around a support. If the rotation angle is more than 360 degrees, it is a full-rotation crane; less than 360 degrees, it is a partial-rotation crane. Fixed, therefore, does not have the ability to rotate around the support.

To summarize, we can state a fact: cranes are one of the most popular construction mechanisms. It’s not for nothing that there are so many types and types of them. As for detailed description their use and design - then this is already material for a whole series of articles.

| Read: | Discuss: |

An effectively functioning water supply system is a modern system, suitable for expansion and modification. Gone are the days when people made do with a few welded pipelines. Nowadays, in any private home, a plumber cannot do without various fittings and water taps.

In this article we will look at water taps, as one of the most important, found almost everywhere, their types and features.

Contents of the article

Purpose

A water tap is a small shut-off mechanism that performs extremely important functions. The standard sample performs a rather trivial, but at the same time absolutely necessary for the functioning of the pipeline task - it controls the movement of the carrier inside the pipes.

There are situations when the pipeline needs to be partially or completely shut off, or one or more branches from the water supply need to be cut off. There are many reasons for this, ranging from a banal breakdown of plumbing fixtures to major damage to the system.

In any case, a breakdown threatens to flood the house or apartment, so it is better to immediately turn off the water supply in order to protect yourself.

You can also turn off the water at the entrance to the main, but then you completely cut yourself off from the water supply during the repair (which, let’s be realistic, may take a long time).

That is why any pipeline of even the slightest decent length is divided into logically understandable sectors or branches, isolating each segment using these same taps. This approach is better and safer than standard assembly, although a little more expensive.

One single turn of the faucet handle completely shuts off the water supply in a particular area. If desired, a water tap can be installed not only on individual branches, but generally at the entrances to any plumbing unit.

In this case, a breakdown, for example, in the water folding mechanism or at the inlet to the water heater, can be easily and simply eliminated. Just turn the tap and...

Note that they use different kinds water taps not only for isolating branches of water supply systems. There are other purposes as well. For example, modernization of the heating system, when taps are placed at the entrances to radiators or to the underfloor heating system, in order to be able to quickly remove or replace the device in the future.

An equally popular option is one that acts as a switch valve, that is, it redirects the flow of water from branch to branch.

Don't forget about the water tap. The best way to imagine how the water dispensing mechanism works is by looking at your bathroom sink. There is one in any bathroom, and only thanks to it you can comfortably enjoy the benefits of civilization.

General operating principle and design

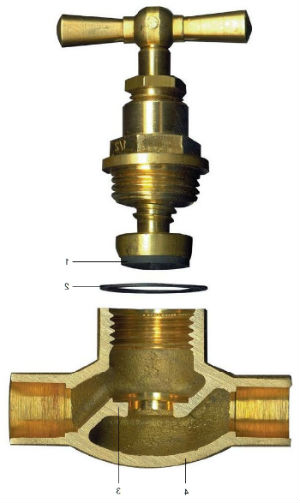

Exist different types taps for water supply, but they all have common design elements. Anyway the faucet consists of:

- body or general body;

- locking element;

- pens;

- seals.

It doesn’t matter whether we are considering valves, a tee with a tap, a water tap, or any other of its varieties. In any case, they cannot do without the four elements described above, although most likely these elements will differ from each other.

The body of the crane depends on the specific task it is performing. A conventional coupling sample is essentially built into the body of the coupling itself. The corner valve has a corner body, because its task is to form corner connections, for example, at the entrances to heating radiators.

The tee has a different body. The tee consists of a branched coupling, which is obvious. Water solutions can be built-in or special. Their differences in the body are much more significant.

The shut-off element in the faucet is the main part. It is with its help that it is possible to stop the flow of water. In civilian taps, ball mechanisms or are used as locking elements.

The handle on the faucet is ordinary and is necessary for control. If we consider it, then the handle can be in only two positions: closed, open. In valve-type faucets, a valve is mounted instead of a handle, and the mechanism is controlled by its spiral rotation.

As for seals, not a single working mechanism in plumbing can do without them. Rubber gaskets are used as seals. In taps, the transitions between the shut-off element and the body are sealed.

Types and differences

When considering the types of such mechanisms, first of all you need to pay attention to their division according to the type of locking mechanism. It is precisely whether there is a ball valve in front of us or not that affects its use in the future.

So, in the tap the locking element can be:

- ball mechanism;

- valve

In the first case, we consider the most common and popular in our time. Ball means that the locking element in it is a ball mechanism.

It is a spherical part with a through hole cut inside. The hole is located on the same spherical plane. Accordingly, it allows water to pass through only in one position.

Let's turn it in a different direction and the water is completely blocked. It is thanks to such a laconic scheme that everything works. In the closed position, the ball mechanism is turned with its blind side towards the flow, eliminating fluid pressure. In the open position, a hole in the ball becomes parallel to the flow, which allows the carrier to be easily transported through the pipes.

The valves are slightly different from the ball samples, because they have a different shut-off element and different functions. It is best used as a regulator of flow states. However, it cannot be installed in an intermediate position. It will be either closed or open, there is no other way.

The situation with valves is different. The locking element in them is a valve, which can be in different positions, from completely open to completely closed. The valve is adjusted by turning the knob, therefore it can be finely adjusted. Gate valves are purchased when you need to not only be able to open or close water, but also regulate its quantity.

Analysis of the properties of a water ball valve (video)

Division by purpose

Also, similar products are divided according to their intended purpose. There are much more differences here and they relate to the basic functionality of this or that part. For example, there are cranes:

- Standard.

- Angular.

- Tees.

- and water folding mechanisms.

The species mentioned above are just the tip of the iceberg, but they are used most often in work, and therefore are best suited as candidates for consideration.

Standard shut-off valves, as a rule, are equipped with ball mechanisms and are ordinary bulkheads for isolating individual sectors of water supply systems. They consist of mostly metal. Such products are installed on all heating and water supply systems without exception.

Corner mechanisms are the same as standard ones, only instead they have a body curved 90 degrees.

A tee with a locking mechanism performs slightly different tasks. A tee is a fitting that has not two, like a regular coupling, but three outlets. The tap is placed on the tee mainly in order to be able, if necessary, to redirect the flow from one branch to another.

The tee is used in heating systems, especially modern ones, where temperature sensors constantly monitor the coolant level and if necessary, mix it with heated water.

The water folding mechanism is essentially the same faucet, but with a valve as a regulator. The simplest water folding mechanism is placed on pipes to regulate the flow force. You can see a water tap in any bathroom. As a rule, it is combined with, creating water taps for the sink that are familiar to the eye.

When choosing this type of product, you should be guided by the working conditions at your site. There are no universal solutions in plumbing. All of them are good, and all are intended for some specific tasks.

For example, a ball water flow blocker should be used in pipelines for situational isolation of individual branches of the water supply system. You cannot buy it instead of taps with valves. Although they are cheaper, they are not designed to regulate the flow force.

At the same time, valves were designed specifically for regulation. The valve cannot be closed in a split second, but it can be left in the half-closed position for a long time, without any negative impact (the ball mechanism in the half-open position wears out quickly).

The owner of an expensive water supply system with integrated heating cannot do without tees, and tees with shut-off valves You can also choose automatic. There are taps with sensors that can switch independently using a conventional relay.

I recommend paying attention to the material from which the faucet is made. It must match the pipe material. For metal we take metal, for plastic we take plastic. Of all the variety of metals, it is best to buy. It does not conflict with steel and copper, and has excellent characteristics.

Load-lifting cranes have a wide range of applications. Most often they are used in construction, manufacturing, ports, railways. Cranes are divided into two main groups: rotary and fixed. They differ from each other in the design of the load gripper, the fastening of the lifting mechanism, the load capacity, and the methods of movement.

Cranes are designed to lift heavy loads, move cargo, and lift it to a certain height. There are many types of cranes used for specific jobs.

Cranes are divided into three main types:

pavement;

boom;

cable.

They differ in design, method of moving and lifting loads. Each group includes several types of lifting machines.

In addition to the design, the main distinguishing feature of lifting machines is their ability to move independently. Mobile crawler and wheeled cranes are used in construction more often than stationary cranes that are fixed to the base and cannot move independently, such as tower cranes.

A distinctive feature is the ability to move

If they can move independently, cranes are divided into 5 main groups:

mobile – having the ability to move around the territory;

adjustable – fixed to the base, able to move;

stationary – monolithically fastened to the base;

radial - moving on rails;

trailed - moving with the help of vehicles on a trailer.

The group of mobile lifting mechanisms includes 5 types of cranes, differing in the methods of movement.

Mobile group cranes are:

wheeled;

tracked;

rail;

pneumatic wheels.

They are used in all areas of construction, industry, and at railway stations. Truck cranes belonging to the jib type can be used anywhere in the city. The carrying capacity of such machines varies.

Medium-tonne machines can work with loads from 10 tons to 80 tons, heavy-duty machines - from 80 tons to 2000 tons. The Chinese company Sinopec Engineering manufactures machines capable of lifting heavy loads. The tracked heavyweight from this company operates with a maximum weight of 4000 tons. Thanks to their mobility and large lifting capacity, they can perform all work with cargo in places inaccessible to lifting machines of other groups.

In addition to differences in the capabilities of moving the machines themselves, there are distinctive features gripping mechanisms for cargo cranes.

Types of load gripping mechanisms

Depending on the size, weight, and design of the load, cranes with a specific gripping mechanism are used. For example, for loading and transporting scrap metal, overhead cranes are used, which use electromagnetic pickup of the load.

Types of gripping mechanisms:

hook - the most common type of cargo grip;

spreader – for lifting and unloading containers of various sizes

grab – for loading bulk materials and soil.

electromagnet;

ticks.

With these gripping mechanisms you can handle any load.

Areas of application for cargo cranes

Tower - used for the construction of objects of any complexity. They are used in shipbuilding and in ports.

Pavements - in production workshops, warehouses, factories.

Console - have a wide range of applications. Due to the fact that the boom rotates 360 degrees, it is used in factories, industrial enterprises, and construction.

Railway – provide reliable unloading and loading at railway stations. Easily move on rails over long distances.

All types of lifting mechanisms are controlled: manual, electric, hydraulic, pneumatic drives.

Do you want to rent a lifting crane? Contact the site