If you own your own car and garage, but prefer to at least occasionally look under your car yourself, then the following is for you. Typically, inexperienced drivers prefer to carry out inspections only at a service station and give their hard-earned money to “specialists”, but even carrying out minor work on changing oil, consumables, monitoring the condition of the units and mechanisms of your car can save your budget. A do-it-yourself overpass made in a garage is the best way out of this situation.

Let's look at the statistics of a survey on the topic of whether it is difficult to make an overpass in a garage with your own hands. 66% of respondents answered that it is quite simple; 14% believe that it is simple, but with minor problems; 16% said it is not easy and will require skills in this area; for 4% this is a very difficult task.

Depending on the size of the garage and the model of the car, you can choose an overpass option that will meet your needs.

Overpasses can be divided into 2 types:

- for full vehicle entry;

- for partial lifting of the vehicle.

The first type will provide more comfortable working conditions for car maintenance than the second.

Overpass options for full vehicle entry

Such a statement will be correct from the point of view of the meaning of this word. But the function of the pit is the same as that of the overpass - to provide access to the bottom of the car.

Such a statement will be correct from the point of view of the meaning of this word. But the function of the pit is the same as that of the overpass - to provide access to the bottom of the car.

The advantage of the pit is that it will not take up useful space in the garage.

If the groundwater level in the area where your garage is located is high, then it is not advisable to consider the issue of an inspection hole.

Otherwise you will have to do extra drainage system(which is very troublesome and expensive), and the bottom of your car will be subject to constant corrosion due to moisture that will collect in the hole.

As a result, you will have to fill it up and consider other options.

Brick overpass

This option is suitable for those who have a garage in a rural area or in the country. This design is carried out by simply laying bricks on cement mortar - along the width of the distance between the wheels of the car in the form of a trapezoid.

The disadvantages of this type of overpass are obvious: a site is required for its construction; brick may deteriorate over time; If you need to vacate the site, dismantling the structure will require significant effort and time from you.

Overpass made of railway sleepers

This overpass is assembled from several railway sleepers, like a children's construction set.

You can lay out 2 bases by stacking sleepers one on top of the other in the form of a slide. Lay tracks across for driving.

To prevent the structure from moving apart during the repair of your car, it must be secured with staples. The disadvantages of this overpass are obvious.

Firstly, not everyone has sleepers in stock. Secondly, sleepers are very heavy; one person will not be able to assemble and disassemble such a structure. Thirdly, after completing automotive repair work, you need a lot of space to store sleepers.

Of course, if you are building this structure in a garden plot, you can leave them in the open air. Sleepers are usually impregnated with creosote, which protects the wood from rotting.

Metal option

If the previous options are possible if there is a plot of land, then a metal overpass can be considered as universal - it can also be used in urban environments.

To make it you will need the following tools and materials:

- rolled metal;

- welding machine;

- fittings;

- grinder with cutting wheels;

- bolts with nuts;

- metal paint.

If desired, you can make the overpass collapsible. This will save space by quickly assembling it when necessary.

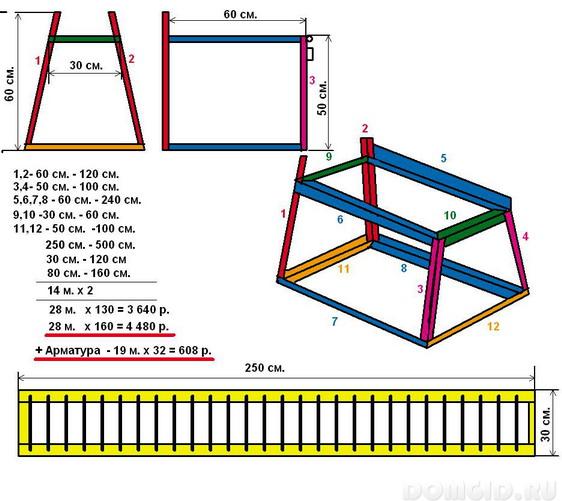

Its design is quite simple. It is necessary to assemble 4 base posts with a height of approximately 50 cm. To ensure stability, it is better to assemble the sides in the shape of a trapezoid and connect them with crossbars of the same length.

A 63 corner (5 mm thick) is suitable for this. To make bridges, you can use 40 angles (4 mm thick) and reinforcement (12 mm is suitable).

The bridges are a metal ladder. It will be necessary to make 2 bridges for driving in and 2 bridges on which the car will stand during repairs. You can calculate the minimum length of the latter yourself by measuring the distance between the centers of the wheels of your car and adding a small allowance.

After the individual elements are ready, they need to be bolted together. In order to provide additional rigidity to the entire structure, you can combine the racks with each other. The bolted connection will allow you to quickly assemble or disassemble the entire structure.

Construction of an overpass for a garage

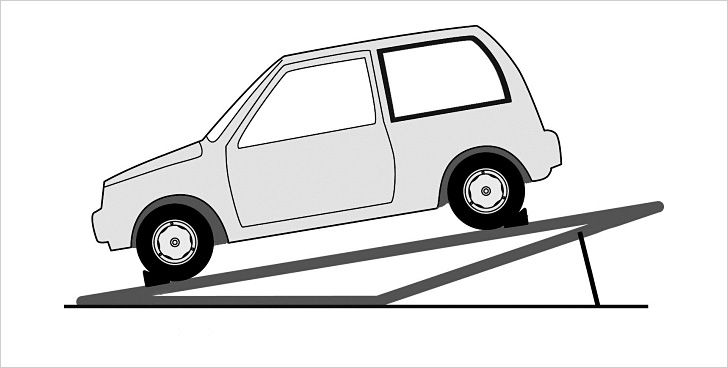

If there is a complete shortage of space, a way out of the situation can be found in the manufacture of mini-overpasses. They refer to overpasses for partial lifting of a car. Of course, working in this case will be less comfortable than with the options discussed above, but much more convenient than under a jacked-up car.

Several options for mini-overpasses

The most basic version of a mini-overpass can be made of wood.

To do this, you will need a board (you can take it 50 mm thick), which is wider than the wheels, and a square wooden strip (for example, 100x100 mm). The height of the cross section will determine how high the car can rise. With the parameters of wooden products recommended above, the lifting height will be 150 mm.

The structure is assembled as follows.

- A block is attached to the top of the back of the board, which will serve as a limiting wheel travel. 2 square-section slats are attached to the bottom: one is slightly further from the middle, the second is on the edge of the board. The structure is ready.

- You need at least 2 such devices (or 4 if you need to lift the entire car off the ground). This mini-overpass works very simply. When you place the structure under the wheel of your car, it rests on the ground at 2 points: the front edge of the board and a block that is secured near the middle.

- Once the car's wheels hit the board and the center of gravity moves closer to the rear edge of the board, the front edge will rise and the rear will lower. Since the supports were made of a block with the same cross-section, the board will take a horizontal position.

- In this case, the length of the board should be such as to prevent it from hitting the bottom of your car. All that remains is to secure the wheels that remain on the ground with stops and blocks. As you can see, such a flyover is very easy to make with your own hands. You can make a mini-overpass from metal. Its design will resemble the metal overpass discussed above, only in a smaller version. It also consists of supports on which bridges are attached.

- It is advisable to weld limiters along the edges of the bridges. This will protect your car from slipping.

- One bridge is located at an angle from the ground for entry, the other is horizontal (if you look at the structure from the side, the outline will be a trapezoid). You can focus on the following dimensions: base length – 80 cm; the length for the drive is approximately 45 cm, the width of the bridges is about 40 cm. The entire structure can be assembled from a 25 mm corner (less than that is not recommended). The approximate weight of the structure will be 20-30 kg. A travel limiter for the wheel must be welded at the rear.

More complex, but effective option mini-overpasses can be made according to the swing-rocking principle. To assemble it you will need welding work. It will be necessary to make 2 frames in the shape of an isosceles triangle. The width of the frames is selected depending on the width of the wheels of your car, and the length of the bridge is selected depending on the length of the car.

To ensure structural rigidity, the frames must be fastened together. To ensure stability of the structure, it is necessary to use spacer stands under the side that will be above the ground. It should be taken into account that for greater stability the center of gravity of the car should be closer to the apex of the isosceles triangle.

When working on overpasses, you should always remember to follow safety measures. The car must be put on the hand brake and the wheels must be secured with chocks.

Let's summarize. You have considered various options and approaches on how you can make an overpass with your own hands. Depending on the available space, materials, finances and desires, you can choose any option for your garage.

This can be either a solid structure or a collapsible version of a metal overpass. Perhaps it will be enough for you to make a wooden mini-overpass. In any case, the choice will be yours.

Hi all.

Hi all.

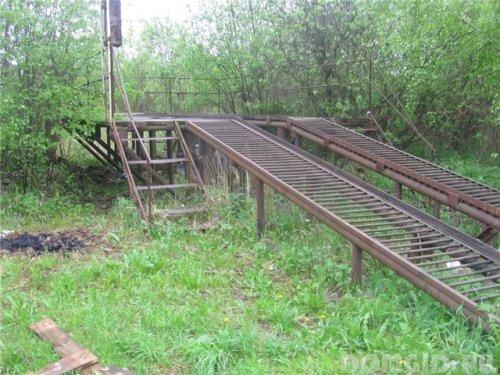

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

","contentType":"text/html"),"proposedBody":("source":"

Hi all.

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

Hi all.

On the territories of some garage cooperatives (and not only) there are sometimes overpasses for car repairs (see photo). A controversial situation has arisen: do we mark such overpasses on the map? As I know, such structures may not be publicly accessible, that is, with elements blocking entry. And there is also a certain tendency towards their elimination. I ask the service team to accept a common opinion, which will eliminate all controversial situations in the future. Photo taken from the site http://kredit-online-samara.ru/

","contentType":"text/html"),"authorId":"106393900","slug":"estakady-dlya-remonta-avtomobiley","canEdit":false,"canComment":false,"isBanned" :false,"canPublish":false,"viewType":"minor","isDraft":false,"isOnModeration":false,"isSubscriber":false,"commentsCount":24,"modificationDate":"Tue Nov 22 2016 19:10:22 GMT+0000 (UTC)","isAutoPreview":true,"tags":[("displayName":"question","slug":"questions","url":"/blog/narod -karta??tag=vopros")],"isModerator":false,"url":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley","urlTemplate":"/blog/narod-karta/ %slug%","fullBlogUrl":"https://yandex.ru/blog/narod-karta","addCommentUrl":"/blog/createComment/narod-karta/estakady-dlya-remonta-avtomobiley","updateCommentUrl ":"/blog/updateComment/narod-karta/estakady-dlya-remonta-avtomobiley","addCommentWithCaptcha":"/blog/createWithCaptcha/narod-karta/estakady-dlya-remonta-avtomobiley","changeCaptchaUrl":"/ blog/api/captcha/new","putImageUrl":"/blog/image/put","urlBlog":"/blog/narod-karta","urlEditPost":"/blog/583311ccce6a0e001fbf4e99/edit","urlSlug ":"/blog/post/generateSlug","urlPublishPost":"/blog/583311ccce6a0e001fbf4e99/publish","urlUnpublishPost":"/blog/583311ccce6a0e001fbf4e99/unpublish","urlRemovePost":"/blog/583311ccce6a0e0 01fbf4e99/removePost", "urlDraft":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley/draft","urlDraftTemplate":"/blog/narod-karta/%slug%/draft","urlRemoveDraft":"/blog/ 583311ccce6a0e001fbf4e99/removeDraft","urlTagSuggest":"/blog/api/suggest/narod-karta","urlAfterDelete":"/blog/narod-karta","isAuthor":false,"subscribeUrl":"/blog/api /subscribe/583311ccce6a0e001fbf4e99","unsubscribeUrl":"/blog/api/unsubscribe/583311ccce6a0e001fbf4e99","urlEditPostPage":"/blog/narod-karta/583311ccce6a0e001fbf4e99/edit","urlForTrans late":"/blog/post/translate" ,"urlLoadTranslate":"/blog/post/loadTranslate","urlTranslationStatus":"/blog/narod-karta/estakady-dlya-remonta-avtomobiley/translationStatus","urlRelatedArticles":"/blog/api/relatedArticles/narod -karta/estakady-dlya-remonta-avtomobiley","ampUrl":"https://blog.yandex.net/amp/ru/narod-karta/estakady-dlya-remonta-avtomobiley","author":(" id":"106393900","uid":("value":"106393900","lite":false,"hosted":false),"aliases":(),"login":"Unknownboy1993","display_name ":("name":"Vova Sh..yandex.ru/get/106393900/islands-middle","isYandexStaff":false),"originalModificationDate":"2016-11-22T16:10:22.084Z"," socialImage":("orig":("fullPath":"http://avatars.yandex.net/get-yablog/4611686018427432610/normal")))))">

Design features of many cars and their specifications involve regular preventive inspection and repair of various components and systems. What can you do, it's just a machine and like any equipment, it requires care and attention. However, if in some cases it is possible to carry out repair work from above by lifting the hood, then any inspection of the suspension and chassis becomes a real pain if there is no inspection hole or overpass. It’s quite expensive to constantly take your four-wheeled friend to a car service center, and it’s not necessary, because many of the jobs can be done with your own hands. Therefore, installing an overpass for cars is a top priority for any car owner who cares about the smooth operation of his car.

Requirements for the overpass

In order to ensure safety and ease of operation, it is better to make the overpass taking into account the following requirements:

- The height of the overpass for car repairs must be at least 1 meter. Otherwise, it will be very difficult for you to get under it, there will not be enough light to inspect the chassis, and there will be no free space for manipulating parts and keys.

- The width depends on the type of vehicle (truck, passenger car), but should not be minimal, centimeter per centimeter. It is necessary to make allowances in the calculations so that the car can drive onto such a platform without problems.

- For greater reliability, it is necessary to provide a safety margin when constructing an overpass. This will help not only to avoid deformation of the structure, but also, if necessary, to roll heavier vehicles onto it.

Types of inspection platforms for cars

In principle, there are only two options for arranging an overpass on your site. Each of them has its own pros and cons and manufacturing features.

Mini overpass, is a portable structure for partial collision. Consists of two separate parts that are not welded together. The car can drive onto such a platform with its front or rear wheels, allowing the owner to carry out repair work.

Plus - this overpass can be used even in conditions of severe lack of free space and can be put aside after repairs. The downside is that driving onto the structure requires pinpoint precision and the elements need to be installed only in places where they will not move in different directions from the push of the wheels.

Full size overpass much more convenient and reliable, but its construction will require free space. But it will last for decades, saving its owner a lot of money, because many repairs can be done at home. The advantage of this design is reliability, strength and durability. The downside is the need to allocate free space and slightly higher costs for materials.

DIY mini overpass for a car

In order to make a mini overpass with your own hands you will need:

- Steel corner with a thickness of at least 10 mm;

- Metal rod;

- Electrodes for welding;

- Welding machine;

- Paint to protect finished metal structures from corrosion.

The load-bearing elements, the “heels” on which the access ladder will be attached, should have a width of about 40-45 cm. The supports are welded in the form of a trapezoid, where the bottom, the base, is 10-15 cm wider than the top. This is necessary to give stability to the structure. The access ladder is made of two pieces of angle with a transversely welded rod, which allows the wheels not to slip when climbing onto the structure.

To fix the car in the desired position, it is necessary to make special gaskets, which are used to prevent the car from spontaneously sliding off the overpass. After completion of the work, the entire structure is painted.

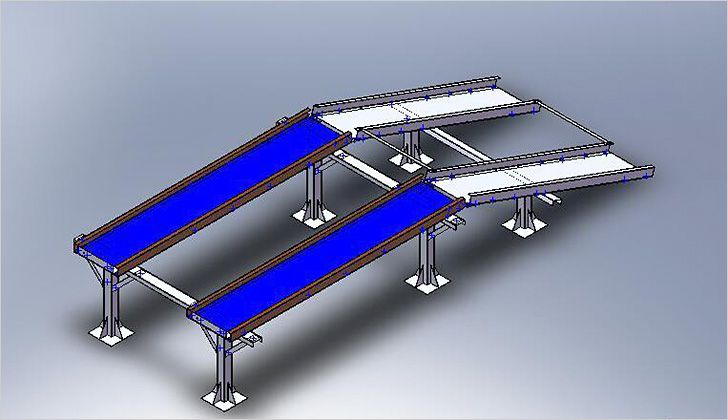

Full-size car repair overpass

Even at the stage of choosing a site for construction, it is necessary to determine the size of the overpass for passenger cars. Since the width of the car and the required length of the platform are not constant values, there is not and cannot be a single size. Today you may have a small subcompact car, tomorrow a huge jeep or a small truck. Therefore, the overpass must be made with a good margin of safety and allowances.

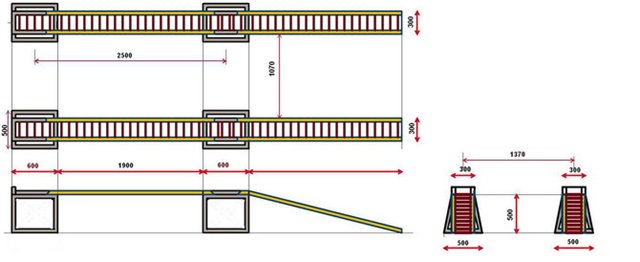

At the first stage of construction, the overpass is dug in steel pipes(6 pieces) with a diameter of at least 80-100 mm to a depth below soil freezing. If you go deeper, there is too great a risk that the structure will move to the side during the first spring thaw. The hole under the post is not filled with soil, but filled with cement.

The inclined part (drive) is made of a metal angle with a steel rod welded transversely. The distance between the rods is about 10 cm.

The horizontal plane is performed in the same way, only at the end of the overpass it is necessary to make a limiter that will protect the car from uncontrolled sliding forward.

As a rule, the length of the inclined part is up to 4 meters, and the horizontal plane is up to 3 meters. This is quite enough to repair a passenger car of any make and design.

As you can see, the question of how to make an overpass for a car with your own hands is solved quite simply.

To do this, you need basic skills in working with a welding machine and some free time. But the result will exceed all expectations and you can not only repair your car to your heart’s content, but also wash it from all sides.

We want to be able to understand and repair everything, so as not to attract outsiders and not pay for it with funds that are now not so easy to obtain. Some delve into the design of various mechanisms simply for the sake of hobby. For both, information on how to build an overpass in a garage with your own hands will be relevant.

When it is not possible to make a viewing hole

Inspection pits have become very popular and widespread. They are relevant for garages with low ceilings, where it is not possible to raise the car. In some areas groundwater are close enough to the surface, and thorough waterproofing must be done so that inspecting the vehicle does not turn into taking a cold bath. If this is also true for you, or you simply don’t want to bother with wasting effort on excavating soil, then an overpass will be the ideal solution.

There are two main types of overpasses:

- stationary;

- collapsible or mini-overpass.

Overpass construction

Many of us have seen stationary overpasses - they can be located on the sides of some sections of roads so that a driver experiencing technical problems can put things in order or temporarily eliminate a car malfunction. It is not difficult to make such a design at home. The main requirement will be the availability of sufficient space. If your garage is designed for two vehicles, then in place of one of them you can build a platform. Materials you can use are brick, floor slabs, wooden beams, metal channel and pipes. The most durable and durable construction will be metal.

Note! With proper construction of the overpass and calculations, you can raise your car almost a meter above the ground.

You will need pipes with a total length of up to 2 m. At approximately 1 m they will have to be buried in the ground and securely concreted. You will need from 4 to 6 such posts, it all depends on the size of the machine. Four corners measuring 7.5 by 7.5 cm are fixed on top, the space between them is filled with reinforcement rods, which are welded perpendicularly. In the same way, the driveway is installed at an angle. It is imperative to provide limiters in the design that will prevent the car from rolling back or driving further forward. The length is selected to suit specific needs.

Other types of overpasses

But not all of us have two cars or large garages in which to play football or hold a party, so it’s worth paying attention to mini-overpasses that can be dismantled or freely moved around the territory and stored in a garage or shed. Making them will require some ingenuity. Here are a few options for you to choose from:

- rectangular trapezoid;

- "rocking chair";

- reversible;

- based on sleepers.

- One-sided pyramid. To make this type of platform you will need a minimum of effort, time and money. You need to have approximately 17 m of boards on hand, 5 cm high and 30 cm wide, maybe less if you are an ace at driving on a narrow gauge railway, but it’s better not to risk it. Next, we cut out two beams of the same length with the following dimensions: 45 cm, 70 cm, 95 cm, 120 cm, 145 cm, 170 cm and 195 cm. After all the parts are ready, you can start assembling - just connect them together so that at one end they create a plane, and at the other they look like a ladder. You can use nails or self-tapping screws - whatever is at hand or more convenient for you. The assembly process should have resulted in two pyramids, cut off on one side. But such an overpass is not yet suitable for a car to drive onto it. The two blocks may suddenly separate and cause damage to the underbody, or the vehicle may overturn. To prevent this from happening, we do the following. On internal sides We mount two two metal corners with holes. Next, choose two metal or wooden slats. We make holes along the edges and attach them to the corners. After such an operation, the stands will not move to the side. When the car is already on top, carefully unscrew the safety crossbars and carry out the necessary repairs.

A similar cut-down pyramid or trapezoid can be made from a metal channel; it will be much more reliable and durable. Instead of climbing with a “staircase”, you will simply need to make an inclined drive.

Note! Using such a device, the car can be raised by 30 cm; if a greater height is needed, add a few more bars of greater length. Be sure to install restraints at the front to prevent the vehicle from rolling forward, and secure the rear wheels.

The “rocking chair” is also a very simple design that any car owner can make. We select two boards as thick as in the previous example, the length can be 1 m. We take four 10x10x30 cm blocks and place them as follows: one of them is on one of the edges, the second is almost in the middle with an offset to the first. We secure it firmly and do not forget to place emphasis. Now, when the car runs over its wheels, the boards will be thrown over due to a shift in the center of gravity; with further advancement, they will be supported by two bars. All! The car is up! Repairs can be made. You can vary the dimensions, focusing on the ground clearance of a particular vehicle and the length of the wheelbase.

There is another version of this overpass, it is a little more complicated to implement, but much more reliable. Designs may vary. Here is one of them. Take a 30×30 corner, larger if possible, adjust the length based on your car. We will need 8 such segments. We connect them in parallel using reinforcement bars. The result should be 4 bases of the same size. The lower parts can be made longer and wider for greater stability. Next we make two stops. One of them will be in the form of a bar, as in the previous example, we weld it to the edge. We install the second one with a slight offset from the middle. But it should be made a little differently - in the shape of an isosceles triangle. We movably connect it to the lower base. If you do not touch the stands, they will be folded at an angle. When the car moves along them, the wheel shifts its center, aligning the horizontal, and rests against the block. Now you can use the latches to secure the platform in this position.

Using a platform is an interesting approach to the matter. To make it, you need to get a corner we already love, or use a square profile. Next, using a welding machine, 2 isosceles triangles are made so that the base is 1.5 times longer than the wheelbase, and the apex angle is obtuse. The platform is placed on them. Now everything is ready. The car drives onto the structure and, resting against the limiters, reaches the end.

Note! Place stands under the rear wheels to prevent the car from rolling away when it is on an overpass.

The sleeper-based trestle is very easy to make. Two sleepers are laid, one in continuation of the other. Strong boards are laid on the part with the recess, after which a small slide is created. That’s it – the platform is ready, you can move in and make repairs. The disadvantage is that the sleepers need to be stored somewhere, although it is unlikely that anyone will decide to take them away from you. For this kind of platform it is not necessary to use sleepers; anything that can securely support the boards will do.

Note! When building a homemade overpass, do not forget to protect your car by installing limiters - they will prevent the car from falling off the overpass.

As you can see, there is no particular difficulty in lifting the machine for servicing. Now you know how to make a flyover from scrap materials that are found in almost every garage. Tell your friends and share your experience.

Video

The video shows a homemade rocking overpass for carrying out car maintenance and repair work on it:

Watch a video about a homemade metal overpass for a car:

Photo

Mini overpass in the garage

A good help in car repair for its owner will be a do-it-yourself overpass in the garage or next to it. But such a design is bulky and takes up a lot of space, and visiting a service station for minor repairs is not always cost-effective. With absence large areas For servicing a personal car, the car repair overpass can be made in another version.

How to make a mini-overpass with a partial collision?

The purpose of such a device is to facilitate access to the suspension and underbody of the car. In this case, only the front or rear pair of wheels is raised to a small height above the ground. During inspection and repair, stops must be placed under the other to prevent accidental rolling off an inclined surface.

The simplest option for making an overpass is ladders. To make them, wood or metal thick enough to support the weight of the machine is suitable. You will need:

- a board with a thickness of at least 5 cm or a metal corner 4x4 with a thickness of 4-5 mm;

- timber (thickness depends on the height to which it is convenient to raise the car);

- grinder and welding machine for working with metal;

- saw, nails for working with wood;

- roulette.

To make it, you need to calculate the length of the board or metal bridge for the wheels to run over so that, when positioned horizontally, this part does not damage the bottom of the car. Making wooden ladders comes down to sawing off 4 pieces of timber for the base and a board for the bridge. The width of the bridge must be sufficient for the wheels to move freely (at least 30-35 cm). Nail the pieces of timber to the boards in the position shown in the figure: in the middle of the ladder and at its edge.

When making a bridge from metal, you need to cut off a corner with a length equal to the estimated length of the bridge (4 pcs.). Connect these parts in pairs with short sections of the same angle or reinforcing bar 15-17 mm in diameter. The resulting “ladders” are able to withstand the weight of a passenger car. On the lower side of the bridges, weld the base from the corner in the form of a U-shaped structure. The height of the base is selected individually. The base posts should be positioned in the same way as in a wooden structure. When hitting the ramp up to the first support of the base, under the weight of the car, the automobile overpass comes to a horizontal position, and its rear part rests on the second support of the base.

There is another option for a mini-overpass. These are 2 small home-made welded structures from a 4x4 corner 5 mm thick in the form of a fixed bridge with inclined entries for lifting one pair of wheels. The length, height and width of each part can be calculated individually, depending on the make of the car. During manufacturing, it is necessary to weld 4 rectangular frames from a corner, connecting them in pairs with crossbars at the bottom. Weld onto the top part pieces of rod or angle along the width of the bridge.

The inclined entrances are welded in the form of “ladders” supported by the front part of the horizontal bridge. The relatively lightweight metal structure can be stored in the garage without taking up much space. If necessary, it can be quickly installed at any suitable site for inspecting the machine.

Full collision with an overpass

This portable design means that the car will be in a horizontal position at a certain height above the ground. This provides greater comfort for the owner of the car during preventative and repair work.

The distance from the surface of the site to the bottom can reach 1 m or more. As an example of how to make an overpass, you can use the drawings in Fig. 3 or develop your own. You will need:

- steel corner 5x5 cm, thickness 10 mm;

- reinforcing bar with a diameter of 17 mm;

- Bulgarian;

- welding machine, electrodes;

- roulette.

Cut a corner for supporting structures according to the dimensions indicated in the diagram. The sections for the outer side of each support should be 10 cm longer than those that will be under the bottom of the machine when the collapsible mini overpass is installed in its working position. This will provide support for the bridges and wheels of the car, preventing their possible drift to the side. 2 supports must also be equipped with transverse stops for wheels at the point farthest from the entrance to the overpass.

Weld 2 trapezoidal structures for each support: with and without the ends of the corner extending above its upper edge. Connect the trapezoids with crossbars about 60 cm long, welding them in the corners of the structures. Having assembled 4 supports, make transverse supports on those that will be installed at the far ends of the overpass.

The length of the bridges and entry inclined parts is determined by personal needs, depending on the size of the car. Their width should be sufficient for convenient passage of the machine on inclined and horizontal surfaces. The bridges need to be welded in the form of “ladders”, connecting the sections of the corner with crossbars of the required length from a rod.

To ensure the reliability of the prefabricated structure, it is necessary to provide holes for fastening with bolts and nuts at the intersection of the bridges with the upper parts of the supports and at the points of attachment of the inclined entrances to them. To bring the overpass into working condition, it is enough to install 4 supports, lay horizontal bridges and install inclined ramps for lifting the car. After completing the inspection and repair, the homemade mini-overpass can just as easily be disassembled into its component parts and can be stored without taking up much space in or near the garage.

With a little skill in working with a welding machine and metal, a do-it-yourself overpass can be made in about a week. The convenient and space-saving design will last for decades. Given approximately the same parameters of passenger cars of different models, it will be useful both when the owner himself changes the car, and for helping a friend if necessary.