Butt Weld Steel Flange (Collar flange) - the connecting part of pipelines, fittings, shafts, vessels, tanks, devices, etc., consisting of a disk with holes for bolts (or studs) and a characteristic axially symmetrical protrusion in the form of a truncated cone ("collar", or "neck" , neck, hub) for butt welding. Collar flange, along with a flat flange, is one of the frequently used connecting elements of pipelines. In foreign industrial terminology, the name Weld Neck Flange, or WN Flange.

Collar flange is used for hermetic connection of separate parts of pipelines high pressures or to sum up technological pipelines to tanks, vessels or apparatus. Application of collar flanges allows, without cutting the pipe (often pipes with a sufficiently thick wall), to break the connection for the dismantling or modernization of a part of the pipeline, in this sense the flange connection is "reusable". The collar (neck) transfers forces to the pipe, reducing the stress concentration at the base of the collar flange. The gradual transition of the thickness from the base of the collar to the thickness of the pipe wall in the weld ensures the reliability of the collar flange. The flange diameter matches the pipe diameter, reducing turbulence and erosion of the flange joint. used collar flange on pipelines where the nominal pressure is 0.1 - 20.0 MPa (1 - 200 kgf / cm²), and the temperature of the working medium is in the range from -253°C to +600°C.

During installation collar flange does not fit on the pipe flat flange, and is welded to it end-to-end with one weld.

Collar flanges GOST 12821-80

Collar flange production is regulated by the domestic normative and technical document GOST 12821-80 "Butt-welded steel flanges for Ru from 0.1 to 20.0 MPa (from 1 to 200 kgf / cm²). Design and dimensions." Wording on English language sounds like " Steel butt-welded flanges for P nom from 0.1 to 20.0 MPa (from 1 to 200 kgf/cm²). Design and dimensions". This document, which standardizes collar flanges, was introduced to replace GOST 12829-67, GOST 12833-67 and GOST 12835-67.

According to GOST 12815-80, 9 different versions are distinguished collar flanges: 1) collar flanges with a connecting ledge; 2) collar flanges with a ledge; 3) collar flanges with a cavity; 4) collar flanges with a spike; 5) collar flanges with a groove; 6) collar flanges with recess for lens seal; 7) collar flanges for sealing gasket of oval section; 8) collar flanges with a spike for a PTFE gasket; 9) collar flanges with a groove for a PTFE gasket.

GOST 12821-80 sets an example symbol when ordering round steel butt weld flange Dy 50 mm on RU 1.0 MPa (10 kgf / cm²) from steel 25, version 1 (with a connecting ledge):

Flange 1-50-10 St 25 GOST 12821-80,

Where:

1 - version of the collar flange;

50 - nominal bore, mm - (D y, DN);

10 - conditional pressure, kgf / cm² - (P y, PN);

St 25 - steel grade from which the collar flange is made.

The appendix to GOST 12821-80 contains a table of compliance with OKP codes (all-Russian product classifier). For example, a collar flange with the designation 1-100-2.5 has the OKP code 37 9941 4290 00, and stainless collar flange the same designation - code 37 9941-5233 05.

We produce collar flanges nominal diameters 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 500, 600,700, 800, 900, 1000, 1200, 1400, 16 00, 1800 mm and above and nominal pressures: 6, 10, 16, 25, 40, 63, 100, 160, 200 kgf/cm². We will also make butt welded steel flanges other diameters according to your drawing.

Collar flanges DIN

Collar flanges according to the German DIN standard (Deutsches Institute für Normung, German Institute for Standardization). DIN collar flanges (Welding Neck Flanges) include flanges manufactured according to the following standards:

- DIN 2627 Weld Neck Flange PN400,

- DIN 2628 Weld Neck Flange PN250,

- DIN 2629 Weld Neck Flange PN320,

- DIN 2630 Weld Neck Flange PN1 and 2.5,

- DIN 2631 Weld Neck Flange PN6,

- DIN 2632 Weld Neck Flange PN10,

- DIN 2633 Weld Neck Flange PN16,

- DIN 2634 Weld Neck Flange PN25,

- DIN 2635 Weld Neck Flange PN40,

- DIN 2636 Weld Neck Flange PN64,

- DIN 2637 Weld Neck Flange PN100,

- DIN 2638 Weld Neck Flange PN160.

- DIN 86029 Hubbed Slip-on Flange PN10, DIN 86030 Hubbed Slip-on Flange PN16.

Collar flange EN

The standards published by the European Committee for Standardization are called EN. DIN EN 1092-1 specifies standards for flanges. Weld-neck flanges are of type (type, typ) 11 - Weld-neck flanges and are available for pressures PN 2.5, PN 6, PN 10, PN 25, PN 40, PN 63, PN 100.

PN (nominal pressure) - conditional pressure, kgf/cm².

Below is a table of conformity between EN 1092-1 and DIN for collar flanges. For EN 1092-1, equivalent DIN standards are specified for each nominal pressure. Collar flange types only described in EN 1092-1 but not described in DIN are marked with a "+". The symbol "-" means that there is no standard for this pressure. The underlined standard numbers are taken from DIN.

| Flange type | Weld-neck flanges(collar flanges steel welded end-to-end) | Hubbed slip-on flanges for welding(collar flanges steel welded) | Hubbed threaded flanges(threaded collar flanges) | |

|---|---|---|---|---|

| Drawing |  |

|||

| EN type | 11 | 12 | 13 | |

| PN | 2,5 | 2630 | - | - |

| 6 | 2631 | + | 2565 | |

| 10 | 2632 | 86029 | + | |

| 16 | 2633 | 86030 | 2566 | |

| 25 | 2634 | + | + | |

| 40 | 2635 | + | 2567 | |

| 63 | 2636 | + | 2568 | |

| 100 | 2637 | + | 2569 | 160 | 2638 | - | - |

| 250 | 2628 | - | - | |

| 320 | 2629 | - | - | 400 | 2627 | - | - |

Collar flange ASME/ANSI

According to ASME / ANSI (ASME - American Society of Mechanical Engineers - American Society of Mechanical Engineers, American National Standards Institute - American national institute standards), collar flanges are called Welding Neck and are manufactured according to ASME/ANSI B16.5 - 1996 - "Pipe Flanges and Flanged Fittings" and ASME/ANSI B16.47 "Large Diameter Steel Flange". ASME/ANSI B16.5 standardizes the production of flanges (including neck flanges) with nominal diameters from 1/2 to 24 inches, collar flanges of large diameters (26 to 60 inches) are manufactured in accordance with the requirements of ASME/ANSI B16.47. This standard describes temperature and pressure conditions, materials, dimensions, tolerances, markings, etc.

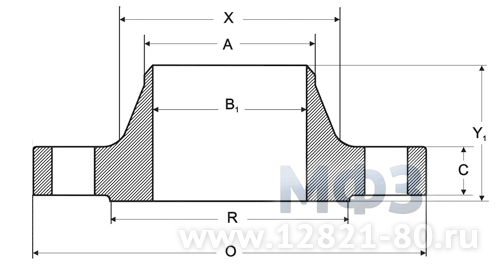

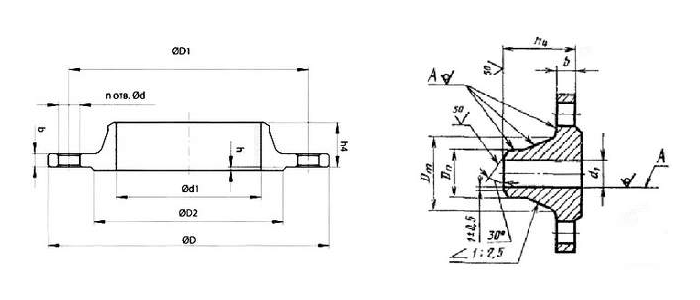

The figure on the right shows the following symbols:

A - collar diameter for welding (neck diameter weld neck, or hub diameter at bevel);

X - collar diameter at the base (hub diameter);

Y 1 - collar length (weld neck length through hub);

C - thickness (thickness);

R is the diameter of the connecting protrusion (raised face diameter);

O - outer diameter (outside diameter);

B 1 - inner diameter of the pipe (weld neck bore);

In accordance with ASME / ANSI B16.5, flanges are classified by nominal pressure into classes (Class, allowable nominal pressure in pounds per square inch): 150, 300, 400, 600, 900, 1500, and 2500. To convert from units " class" in kgf/cm², divide the "class" value by 6. ANSI/ASME B16.47 includes classes 75, 150, 300, 400, 600, 900.

Non-standard collar flanges according to the drawing

Non-standard collar flanges, made according to the customer's drawing, are necessary if it is necessary to connect two pipelines built to different standards, or parts of pipelines of different standards.

The use of various steels for the manufacture of neck flanges

The collar flange is made by processing a cast ring billet from the following steels: 3, 20, 20FA (structural high-quality carbon), 09G2S (structural low-alloy for welded structures) - collar flanges for cryogenic temperature conditions, 13HFA; 15X5M (heat-resistant collar flanges); stainless collar flanges made of corrosion-resistant steels 20X13, 14X17H2, 08X18H10T, 12X18H10T, 06XH28MDT, 10X17H13M2T, 10X17H13M3T, 10X11H23T3MR.

A collar flange is an element that is used to connect equipment to the pipeline with an additional "skirt" ring. The collar flange on the welded ring contains two parts: a ring and a flange of the same circle size. Collar products are a kind of flanges that stand out for their particular practicality of installation. They have the ability to more easily match the bolt holes of an unoccupied flange with the bolt holes of an equipment flange without turning pipe fittings. This is ensured by the fact that the process of its installation begins with welding of one ring, when the flange remains free.

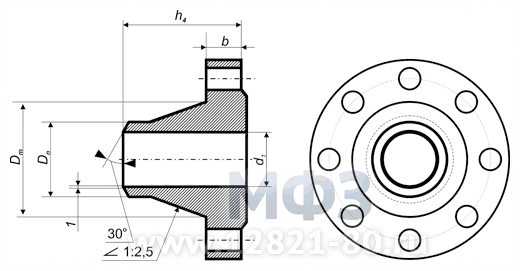

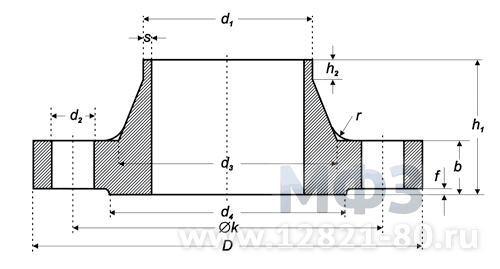

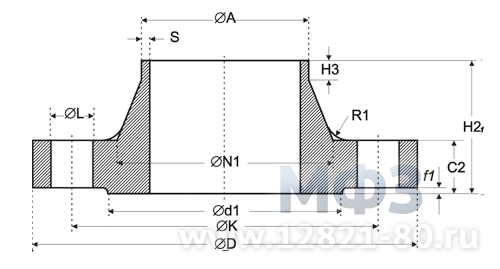

Drawing and symbols

Dy - conditional passage, mm;

D - outer diameter, mm;

D1 - center distance, mm;

d - bolt hole diameter, mm;

Dm - collar diameter at the base, mm;

Dn - outer diameter, mm;

d1 - inner diameter, mm;

b - thickness, mm;

h4 - collar height, mm;

n - number of holes for bolts, pcs.;

m - mass, kg

Application area

Collar flanges are used for tight connection of individual elements of alloy steel pipe fittings. Another of its functions is to bring pipe fittings to devices, vessels or tanks. Strict matching of the size of the pipe circumference and the flange reduces the erosion of the flange connection and turbulence. The pressure on pipelines where a collar flange can be used should be 0.1 - 20.0 MPa.

Flanged connections are well suited for the installation of process pipelines in hard-to-reach places. A variety of materials that underlie them, allow them to be used in almost all environmental conditions. For example, they are widely used in a wide variety of fields, including the oil industry,.

Application temperature for collar flanges

Buy collar flanges

You can buy collar flanges in Moscow at RemMechService LLC. In our work we use only high quality materials and precise equipment.

Pipeline connecting fittings form several groups of parts for mounting pipeline parts or connecting containers, units and other types of equipment to it by tightening with bolts or studs. This type of product includes collar flanges, the design of which is somewhat different from similar products. They have a conical protrusion along the diameter of the pipe and are butt welded with this protrusion to the pipe.

| Buy | |||

| 1 | Collar flange 1-15-25 st.20 GOST 12821-80 | ||

| 2 | Collar flange 7-100-63 st.20 GOST 12821-80 | ||

| 3 | Collar flange 1-150-40 st.09G2S GOST 12820-80 | ||

| 4 | Collar flange 1-300-160 st.15X5M GOST 12820-80 | ||

| 5 | Collar flange 1-400-25 st.20 GOST 12821-80 |

How are collar flanges and other fittings made?

Butt-welded steel flanges are identical in the manufacturing method to the manufacturing methods for similar types of shut-off pipe fittings. They can be made by:

- electroslag (TSEShL) centrifugal casting;

- forging parts;

- hot stamping;

- steel strip bending;

- gas cutting;

The company uses in its work all methods of manufacturing steel collar flanges with invariably high requirements for the quality of its products. The most convenient and, of course, profitable area is cooperation on an ongoing basis. By becoming a regular customer of the company, you will immediately feel all the benefits of your position, first of all, it concerns participation in promotions and other events related to cheaper products. Plus - excellent quality and timely delivery.

Features of valves

Since the role of shut-off valves, in particular steel collar flanges, in the operation of pipelines and equipment is enormous, the requirements for them are very high. Reliability engineering system directly depends on the quality flange connections pipeline parts. Modern technologies allow to produce stop valves very high quality.

Continuous monitoring of product quality standards, corrosion resistance of products, resistance to aggressive environments- an incomplete list of requirements to which collar flanges are subject. To withstand aggressive environments, preference is given to stainless steel products. Collar flanges can be used both as independent fasteners and in combination with rings, gaskets, washers and other sealing elements.

Shut-off valves, which include collar flanges, are the key to the tightness of the pipeline, so the requirements are comparable to the operating conditions.

| Manufacturing Method | Regulatory document | Specifications | Order designation (example) |

| From high-quality rolled metal or blanks obtained by hot forging / stamping, followed by mechanical processing | GOST 12821-80 | Flanges are manufactured from DN 10 to DN 1600, execution of connecting sizes - 1 - 9. | Butt-welded steel flange DN 200 mm on PN 6.3 MPa (63.0 atm) from steel 20 with a connecting ledge version 2 |

| Nominal pressure from 0.1 MPa (1 kgf/cm2) to 20.0 MPa (200 kgf/cm2) | Flange 2-200-63 st.20 GOST 12821-80 | ||

| Medium temperature from minus 253°С to plus 600°С | |||

| They are used to connect pipeline fittings (gate valves, valves, gates) to pipelines and pipelines to equipment (pumps, tanks, heat exchangers), as well as to connect individual sections for pipelines to each other |