Sealers are the most important part of an entrance iron door in each house. If suddenly you notice that cold air has begun to blow in the corridor, and you can perfectly hear what the neighbors are doing outside the door, in the entrance, then it's time to think about seals.

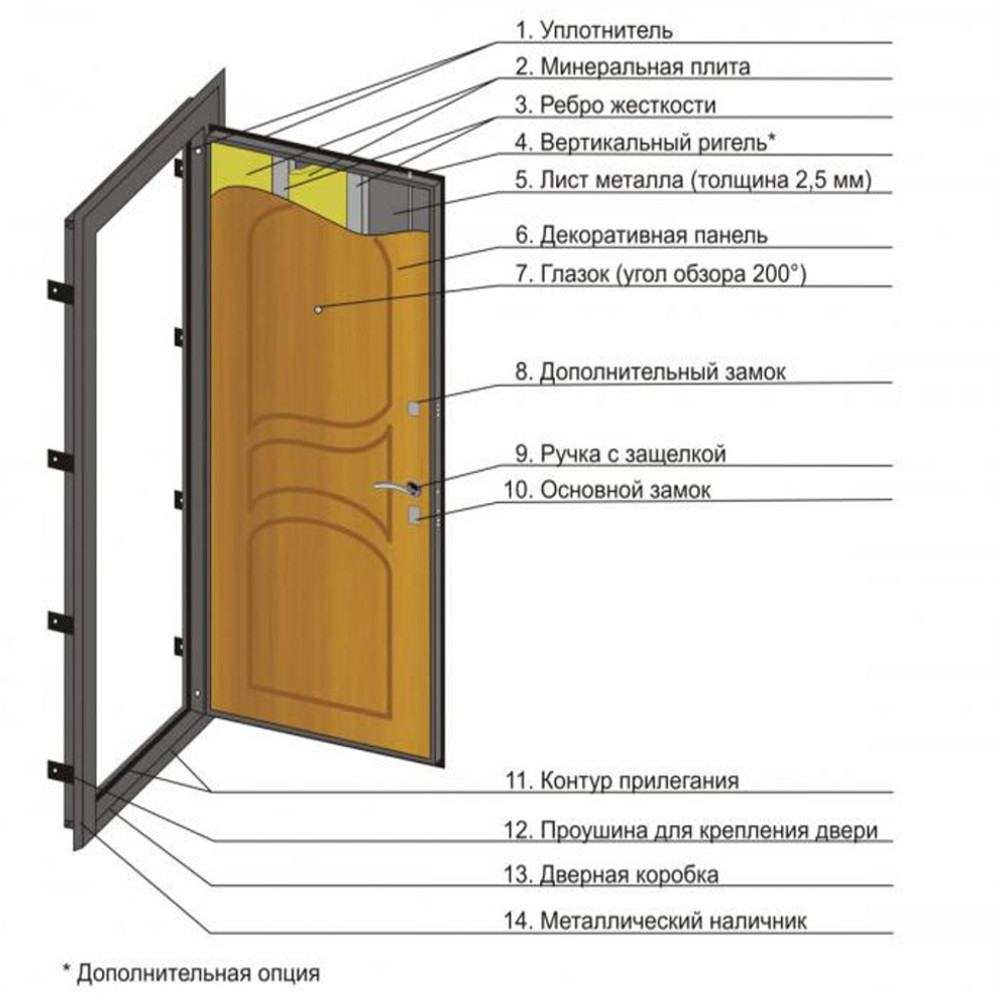

What is a sealant?

Seals are a material that serves as a kind of "protection" for the front door. In addition, the material has excellent sound insulation and thermal insulation, the effect of which is enhanced by a special porous filler.

In most cases, metal door seals come with an adhesive base, so gluing them is not difficult. Of the minuses, the same reason can be distinguished: how quickly they stick, they can also come off quickly.

However, not all seals are identical in appearance and installation method. There are also interior door seals, which have less noticeable sound and heat insulation qualities, as well as seals for plastic doors.

In this article, we are talking about seals for entrance doors, and they, in turn, are divided into several types and subspecies, depending on the type of material, installation method or type of product.

What are the types of sealant?

So, seals, of course, do not have one type and method of installation. The sealant is selected taking into account the features and requirements of the door.

For example, according to the method of installation, the sealant is divided into an adhesive-based product (self-adhesive) and a product that must be installed using screws or self-tapping screws. It is noteworthy that the first type is installed specifically on metal entrance doors, and the second - on wooden entrance doors.

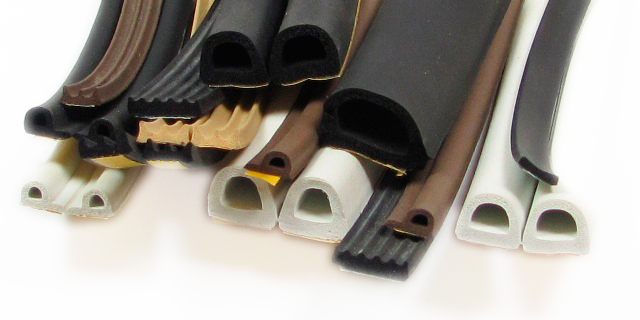

Seals also vary in material. For example, the highest quality seal is made of rubber. It does not let in cold air from the street, and serves its owners for a long time and reliably. Usually rubber seals are self-adhesive and are installed on metal entrance doors. Silicone seals are less resistant to weather conditions, so they are used mainly in the installation of interior doors, where it serves in an excellent way. And finally, the most a budget option- foam seal. The negative properties of foam rubber, which affect the quality of the product, are a complete inability to withstand temperature extremes, which leads to compression and, subsequently, to crumbling of the foam rubber filler, on average, a year after the start of operation.

There are also sealants for sliding wardrobe doors - brush or fleecy tapes. They do not have the qualities of heat and sound insulation, as they are unnecessary. The "purpose" of these seals is to keep dust and dirt out of the cabinets.

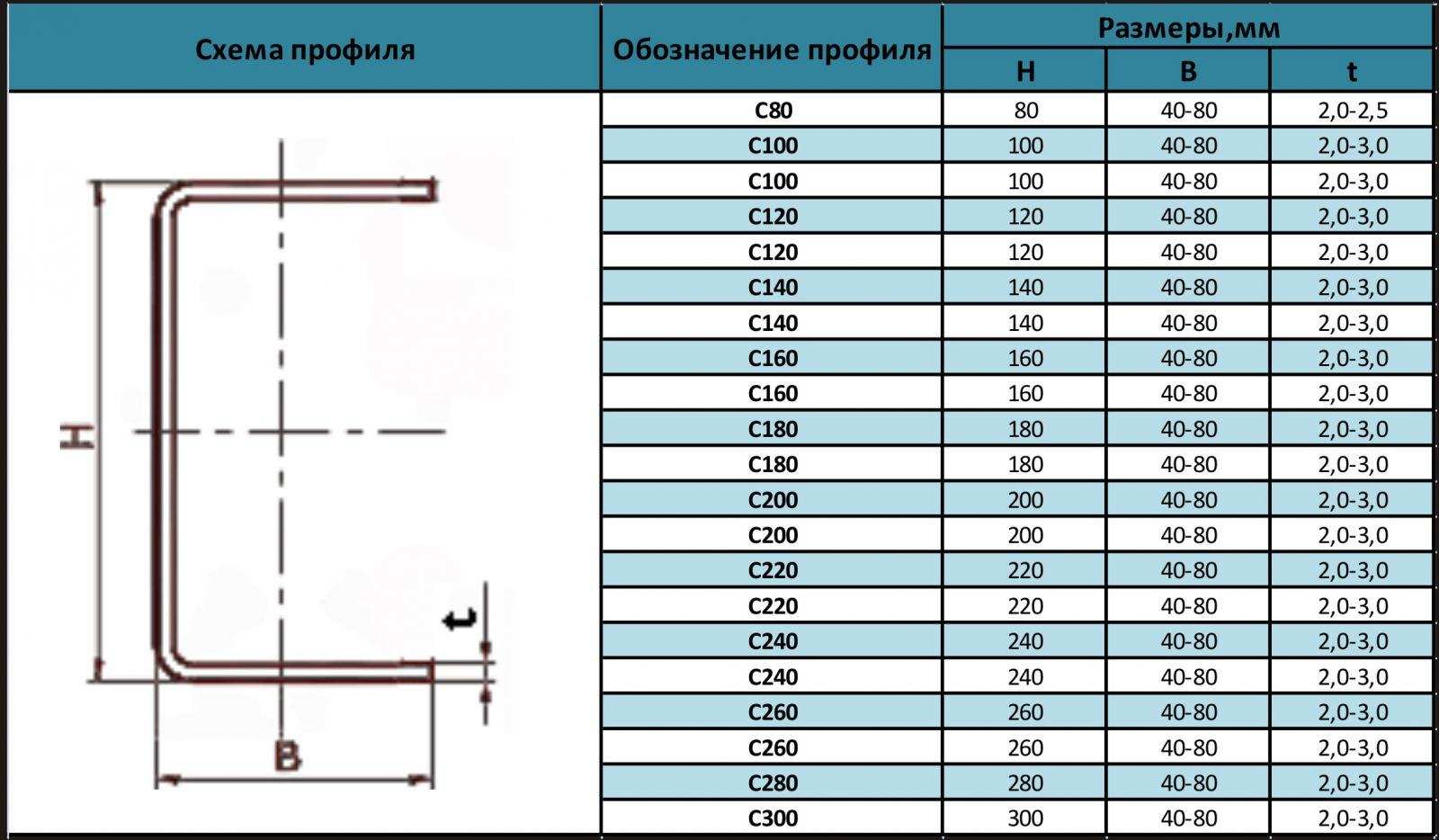

When installing seals in the slots of the entrance doors, it is worth remembering that the products are divided according to peculiar “profiles”:

1. C-profile - installed in a slot with a gap of no more than 3 mm.

2. Profile Type E (K) - Helps seal gaps of the same size, however, is a higher quality product due to the double groove, which best protects against drafts and excessive noise.

3. P - profile - seals gaps up to 5 mm. It got its name because of the peculiarities of the cross section, which in the section resembles the letter "P".

4. V - profile - also "closes" gaps up to 5 mm.

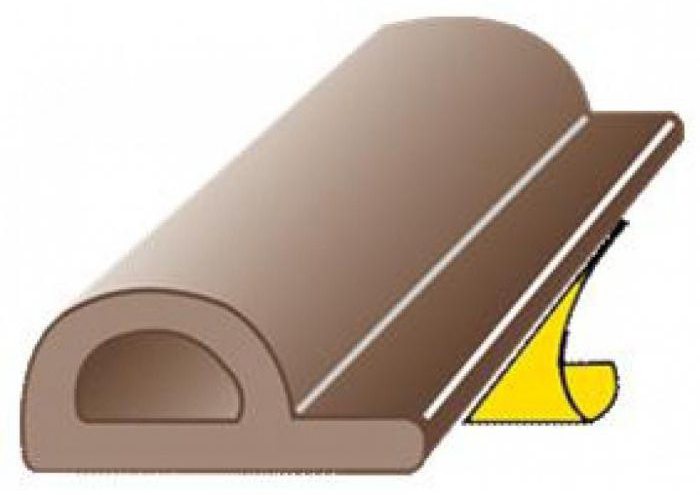

5. D - profile - helps seal up to 7 mm gaps. The name was given due to the fact that in the shape of the cross section it has a pronounced letter "D".

6. O - profile - insulates gaps larger than 7 mm. Due to its cavity, the sealant of this profile can be installed in smaller slots.

Let's dwell on the profiles of type D and E, how to install them?

How to seal iron doors yourself with self-adhesive D and E profiles

As you know, many modern metal doors already come with a seal installed taking into account the design features. When choosing a door, we advise you to focus on such models. But it is not always possible to choose something suitable, and if you bought a door without a seal, it does not matter. Installation of these self-adhesive seals will not be difficult even for novice “household craftsmen”. However, you need to remember some of the subtleties of these seals before installation.

First, you need to know what gap the door has. If this gap is not very large - from 1 to 3 mm - it will be necessary to get by with an E-seal, but if this gap is large - about 7 mm - then you cannot do without a D-seal.

However, these seals are very easy to install as they are self-adhesive.

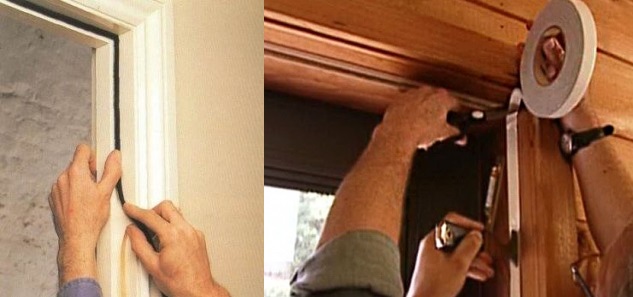

An approximate algorithm for self-assembly of a sealant for any of these profiles looks like this:

1. First you need to stick plasticine of the desired thickness between the door and the frame. Then very strongly close the door and immediately open it. It turns out a kind of "cast" of the required thickness. We directly glue the seal itself, taking into account the size and thickness of the gap. Carefully remove the sticker and, in the course of work, glue the seal along the entire length of the frame. At the bottom of the door, cut off the remnants of the seal with a knife. Installation can be considered complete. It happens that after a while the seal comes off. You can stick it on a strong glue, such as "Moment".

How to seal iron doors yourself with a magnetic seal and an elastic band?

It should start with the fact that it is impossible to install a magnetic seal on your own. This will require a master. So what is the essence of magnetic seals?

This type of seals is mainly installed on the doors of refrigerators. Such a seal works by attracting magnets with the help of attraction poles. If on refrigerators, for the most part, magnetic seals with two circuits are installed, then on an iron door - with three, for best work designs. Magnetic seals are already included with the door, and are not really that great. The fact is that in the case of a strong attraction of the magnet, difficulties may arise with the operation of the door. A child, and sometimes not even every adult will be able to cope with such a design, and if the attraction of the magnets is weak, then why install such a seal at all? After all, if you buy it separately, it will come out for a considerable amount!

However, there is a major plus in this design: the door will no longer slam when opened, because the attraction of the "poles" is in effect, so the neighbors will not hear how you enter or leave the apartment. Perhaps, for the sake of this, it is worth buying such a seal.

If you do not want problems with the installation of the seal, perhaps you can advise you to purchase special sealing gum. Moreover, this method is the easiest. Such a thing is glued into a special recess in the door frame. The mechanism for installing rubber bands is as follows:

1. First you need to measure the box by area. That is, how many meters of sealing gum are needed for this door.

2. Measure the width of the recess in the door frame.

3. To measure the thickness of the seal, you need to take plasticine, wrap it in cellophane and clamp it in the door. The thickness obtained in this case will be, in fact, the thickness of the future sealant.

4. Go to the store and buy the right one sealing gum. There can be no difficulties with the process itself, since this gum is self-adhesive.

Installing the rubber seal

When you began to feel extraneous smells, sounds and even cold in the house, this indicates that the doors began to close tightly. To solve the problem, it is necessary to install a seal. You can do this on your own if you choose the right product.

Today they can be obtained from various materials, each of which has its own performance characteristics. In addition, the installation of the seal can be carried out in a groove or due to a self-adhesive base. Let's take a closer look at the latest version of the products.

Before choosing a sealant with a self-adhesive base, you need to figure out what its functions are:

- Protects from wind, cold air, which penetrate through the gaps in the doors.

- Protects against penetration of moisture, dust, pollen, smoke and even insects.

- Reduces external noise.

- Keeps heat and maintains the optimum temperature inside the house.

- It softens the blow in the event of a sudden closing of the door, and also protects against the formation of microcracks. Thus, it is possible to extend the life of the door structure.

- Saves on heating and electricity bills.

On the video - self-adhesive door seal:

Rubber products

Seals made from rubber are classified as universal. They can be used to eliminate gaps in door structures made of wood and metal. Thanks to the self-adhesive base, the installation process is notable for its simplicity. This procedure will take no more than 5-10 minutes. All that is required for this is to simply attach the product to the end of the sash with a sticky base and press it a little.

Rubber self-adhesive door seal

Rubber self-adhesive door seal Many rubber seals are resistant to high temperatures, acids, alkalis, fats and oils. All this has a positive effect on the service life of the products in question.

When choosing a rubber seal with a self-adhesive backing, the service life must be taken into account. For these products, it can be 3-10 years. This indicator depends on specifications material. But you can determine the wear of rubber by its appearance. Over time, it will lose elasticity, become stiff and crack on its surface. All this indicates that the seal needs to be replaced.

From foam rubber

This version of the seal is presented in the form of a foam tape. It may have different thicknesses. The process of its attachment to the surface is carried out using special glue or liquid nails. The price of such a product is low, so the number of flaws is decent.

foam rubber

foam rubber The biggest downside is the poor insulation. If you use a foam rubber seal, then it will not be able to protect windows or doors from cold air getting inside. But the thermal insulation of interior door structures using foam rubber is a great opportunity to improve the heat and sound insulation qualities of the door, as well as to achieve its tight fit.

When choosing a tape made of foam rubber, you can give preference to seals, the fixation of which occurs both with glue and with a self-adhesive base.

Silicone

This material is inferior to rubber in its performance. The main disadvantage of silicone is the inability to upgrade it with special additives. Although even with the use of additional components, the service life of silicone will not increase. For this reason, it is used exclusively for interior door structures.

Silicone

Silicone Polyvinyl chloride insulation

This seal is made from PVC. It is perfect for doors and windows made of metal, plastic or wood. It is characterized by resistance to the negative effects of direct sunlight. PVC tape is not affected by temperature fluctuations and at the same time does not lose its insulating qualities. It is actively used in everyday life and at industrial facilities. Such material as polyvinylchloride differs in the high durability and long service life.

PVC

PVC Since the tape has a self-adhesive base, the installation process does not take much time and effort. In addition, such work can be done by a person who does not have special skills and experience.

From thermoplastic elastomers

This material is excellent for sealing window and door structures. Such a demand for products made of thermoplastic elastomers is due to the fact that they have many advantages, which include:

Installation

The process of mounting a sealant with a self-adhesive base can be carried out on door structures made of metal or plastic. Once you have been able to select the appropriate material for the seal, you can proceed to the installation process. At the same time, the more expensive your door is, the better the sealant should be.

Installation is quick and easy. Important in this matter is the choice of the thickness of the material and its profile. For these purposes, you should use in a simple way: take plasticine, wrap it in polyethylene, and then put it into the slot and close the doors. After opening, you will have a cast of the desired thickness of the seal.

On video editing door seal:

The process of fastening the product is carried out as follows:

- Degrease the attachment point.

- Remove the protective film from the material and attach it to the door rebate with the sticky side. Squeeze a little.

- If after installation the tape is lagging behind, then you can solve this problem using glue Second or Moment.

Manufacturers and prices

You can buy a door seal with a self-adhesive base from the following trusted manufacturers:

A seal with a self-adhesive core for a door is a fairly popular product today. And this is due not only to the ease of installation, but also to the wide selection of the range. In the hardware store you can see that the seal can be made of various materials, each of which has its own performance.

Sections of the article:

One of the main tasks that front doors and windows perform is to reduce heat loss, as well as to keep cold air from the street. New doors and windows do the job well. But after some time, the owners of doors and windows are faced with a situation where the design loses the fit of the elements, and with it the precious heat.

The modern world constantly pleases with various novelties. In all areas of repair and housekeeping, it is already impossible to count the huge number of useful little things that are worthy of attention. One of these innovations is a self-adhesive sealant. With it, you can easily restore the tightness of the parts for the doors.

The main functions of seals

The main problems that these details solve are protection from various natural phenomena, as well as shock mitigation when closing. Seals help to forget forever about drafts and wind that can enter through the cracks.

In addition, these elements are an obstacle to the ingress of dust, moisture, pollen from various plants, smoke, insects. All this can enter the room through open cracks. Even with the help of various sealing materials, the level of noise from the street is significantly reduced. Thanks to these details, the door or window closes as tightly as possible.

Self-adhesive seal - convenience and practicality

Today, a lot of different sealing materials are offered, but many of them need to be installed in a special way, which is not suitable for all cases and not every person can handle it. The self-adhesive seal for doors or (can also be used for windows) allows you to achieve maximum tightness with a very simple installation.

The practicality of self-adhesives is that you can stick them anywhere. They adhere well to any type of surface, be it wood, plastic, metal. These products are reliable and discreet, do not require any maintenance or other costs. In addition, they will not be able to spoil the surface of the products. If it is necessary to remove the seal, this can be done just as easily as installing. At the same time, even the slightest trace will not remain on the surface.

And even more - modern sealing materials do not absorb moisture, do not accumulate odors, do not oxidize, do not crack from exposure to direct sunlight, they are not eaten by insects. Seals can be used at extreme temperatures. They can retain their characteristics for a long time.

Self-adhesive sealants for doors and windows: types

There are several types of these parts. All differences are based on materials of manufacture. The modern market offers several options.

Rubber products are most often used for entrance street doors. Due to the fact that various modifiers are used in the composition, this material is ideally adapted to various conditions (and even extreme ones).

Silicone elements are slightly inferior in characteristics to rubber. Even with additives, silicone will not have the necessary durability. Therefore, a silicone self-adhesive seal is used, as a rule, only for interior doors. Here he has practically no competitors and his service life will be very high.

Foam rubber varieties are a budget solution that is not able to serve its owner even half a year. Due to constant temperature changes, dirt, dust, high humidity, foam rubber crumbles and crumbles. During operation, the seal will shrink and lose its quality.

Another type of sealing products is the so-called fleece tape. This solution is ideal for compartment doors and nothing more. They do not provide high noise and heat insulation. The main task of such a part is to prevent the penetration of dust.

Polyethylene foam products are ideal for both windows and doors, although they are quite expensive. Among the characteristics - excellent noise and heat insulation, protection against condensation.

Varieties of self-adhesive seals for their intended purpose

According to the range of tasks and purpose, all door seals can be divided into several groups. So, there are products for the front door, for door panels made of glass, wood, metal.

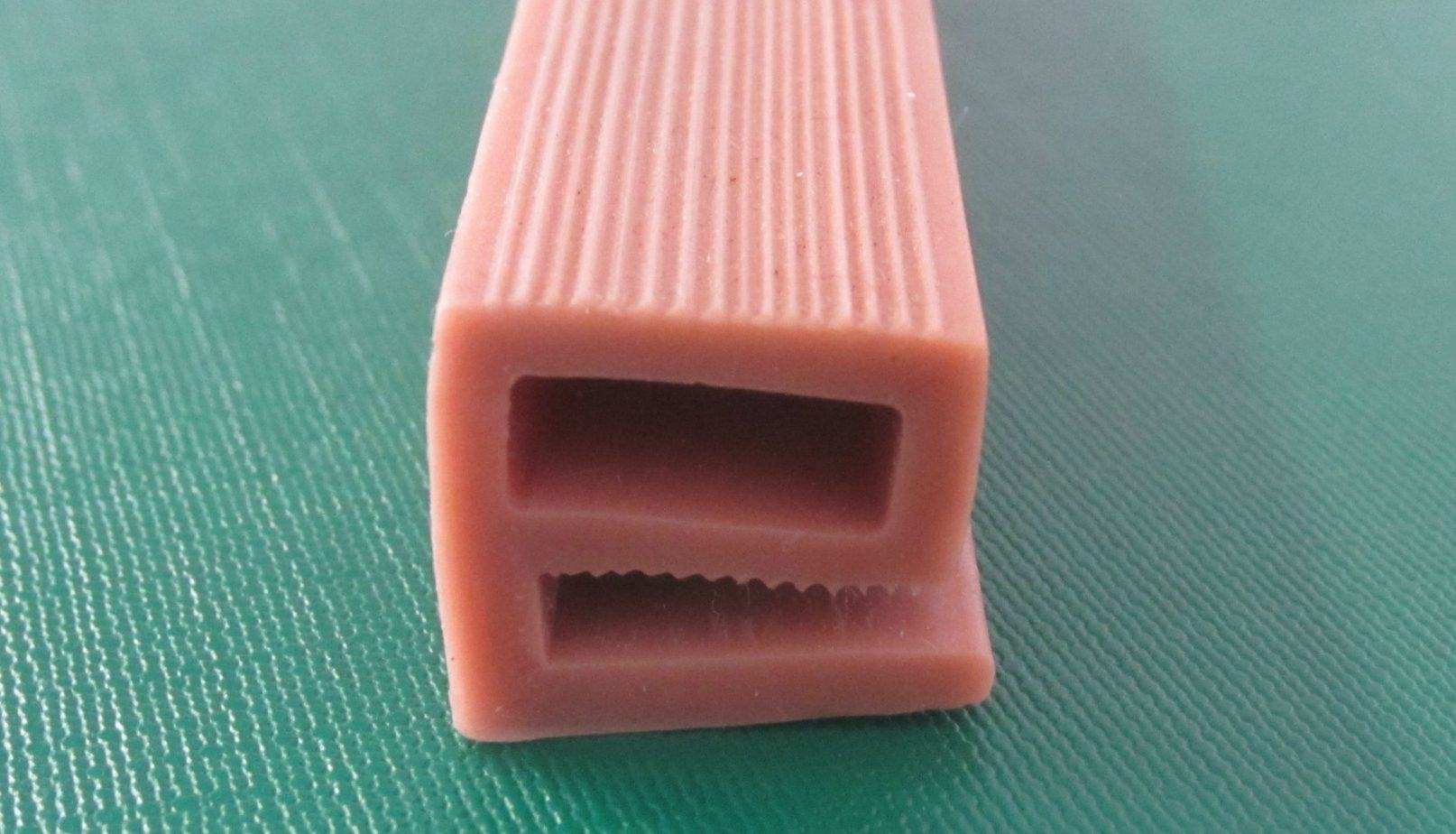

Entrance door products

Self-adhesive sealant for metal entrance doors is nothing more than a dense tubular profile with a cavity inside. Due to the fact that the product is made of a sufficiently thick material, as well as due to the presence of an internal cavity, the door leaf fits as tightly as possible to the door frame.

In addition, the material used to make the seal is also very interesting. It is quite porous, which can greatly enhance the effect of thermal insulation. So, some manufacturers claim that such products can increase heat savings by 10 or more times.

Sealing elements for interior doors

If we compare this group of products with models for entrance doors, then this option does not have simpler characteristics. For example, this element does not need to protect the premises from drafts.

![]()

Due to the low requirements for the production of these elements, other materials are used. It's either silicone or very soft rubber.

Glass door seals

They are a separate species. Often, silicone is used as a material. The difference is in the special section of the profile. Installation of such a self-adhesive seal is quite simple and unpretentious - you just need to stick it.

Advantages of self-adhesives

So, these types make it very easy and profitable to solve all problems with cracks and gaps in door and window structures. This entails a reduction in energy costs, as well as a significant reduction in noise levels.

Self-adhesive elements are very easy to use, and their installation does not require any special skills. And another plus is durability.

Features of self-adhesive sealing elements

For maximum sealing in interior doors should be used different shape profiles. The sections resemble Latin letters, the names are appropriate.

For small gaps that do not reach 1 mm, use the "I" profile or an ordinary rectangular profile. If the gap is up to 3 mm, then it is recommended to use "C" and "E". For gaps of medium sizes from 3 to 7 mm, it is worth using "P" and "V". For deeper ones, “D” and “O” are offered.

Self-adhesive rubber seal designed for doors, in addition to being able to effectively retain heat and protect against drafts and noise, is also an excellent shock absorber. This property helps to significantly extend the life of the door structure. For a very long time, the structure will retain its original shape, will not deform or crack.

Installation of seals

This procedure is quite simple, but still it is necessary to do all the work according to certain rules. So, all actions will be divided into a number of stages.

The first step is to prepare the surface. First, it is necessary to completely remove the old sealing elements (if any), and thoroughly clean and degrease the gluing points. It is very important to completely remove all dirt and dust.

Then a new self-adhesive insulation is applied. It is important to choose the right profile and material so that it fully matches the characteristics and dimensions of your doors or windows. You should also carefully consider the color - it should be in harmony with the product where it will be mounted.

Glue the seals first on the top of the windows or doors. Then - on the bottom, and then on the side parts. After two hours, you can fully use the door or window for its intended purpose. The adhesive composition on the sealing profile is of very high quality - it adheres strongly to the surface and will not peel off during operation.

When buying, it is most profitable to purchase material for all windows and doors at once - the sealant is supplied in large coils of 40 m. All the advantages of such products can be assessed as soon as possible after installation. In winter, the effectiveness of these elements will also be clearly visible.

If the seal will be installed on the front door, then some installation features should also be mentioned. In order to obtain the maximum level of sealing of the door entrance structure, the sealing elements must be glued not only on the surface of the door frame, but also on the door.

Along the perimeter, it is necessary to glue the place where the canvas will adhere to the outside of the box. The place where the canvas fits to the inner quarter is also glued. In this case, the seal is not glued to the surface of the door, but directly to the box. This is a real double protection that can reliably protect your home from drafts, winter cold, extraneous sounds.

So, a self-adhesive seal is an effective solution to the issue of heat and sound insulation. The product is easy to install, the service life is quite high. When choosing, the main thing is to choose the right type of product. This will help ensure a decent level of adhesion to surfaces.

If suddenly a feeling of a draft appeared in a house or apartment, or street or porch smells began to be felt, then this indicates that the door has ceased to close tightly. You can solve this issue on your own by purchasing door door seals.

Entrance doors often frustrate their owners by failing to cope with their main task - keeping the heat in the room. Doors from the inside can be filled with insulation, but if they do not fit snugly against the door frame, then they are ineffective and play a minimal role in maintaining the internal microclimate.

What are gaskets for?

Self-adhesive door seal. Material setting

On modern metal and plastic doors, manufacturers install a special seal that can last from several months to several years, depending on the cost, the more expensive the door, the better the seal. Cheap exterior doors have low-quality plastic seals that soon become unusable.

It is not difficult to install a self-adhesive door seal for doors on your own - it is important to choose the right thickness of the material and its profile. To do this, you can apply the method used by our fathers and grandfathers: wrap a piece of plasticine in polyethylene, put it in a slot and close the door tightly. After opening the door, the approximate thickness of the future seal will be obtained with the doorway closed.

The door seal for doors is fastened quite simply: before installing the material, it is necessary to degrease the attachment point, then the protective film is gradually removed from the material from the sticky side and pressed tightly against the door fold. Some manufacturers save on glue for a sticky surface, and such a sealant soon begins to lag behind the door. To correct this situation, you can use quick-drying glue, for example, "Moment" or "Second".

Conclusion

Summing up all of the above, we come to the conclusion that a door seal is the tool that can save a house or apartment from the penetration of foreign sounds, smells and drafts from the outside. This is especially true for cheap doors, which are often sold without a seal or on which there is a cheap sealing material that quickly becomes unusable.

Seals are different in quality of workmanship and appearance. Each of them is designed to close door gaps of different widths. Therefore, before installing the seal, you should decide on its profile, so that later you do not have to reinstall it again.

Seals come in different materials: rubber, foam rubber, plastic, and so on. The most common are rubber, as they are more durable, better and more reliable. They are easy to install on doors and door jambs and just as easy to remove. The most important thing to remember: before installing the material, it is necessary to remove debris, dust and degrease the surface where the seal will be glued with a solvent or alcohol. Otherwise, it will definitely peel off during operation, and you will have to buy a new one.

Experts also advise not to pursue colored sealants, since due to the color pigment added to the material, it loses its qualities under the influence of weather conditions.

IN Lately These self-adhesive door seals have gained popularity among professionals and housewives alike. These EPDM rubber seals have been developed in Europe for a long time. But they have become popular only now.

There are many different seal profiles. We have three main types of door seals. These are E profile seal, D profile seal and P profile seal.

The main difference between these seals and conventional door seals is durability. Service life - up to 10 years! Important, before you buy a door seal, be sure to carefully measure the size of the gap that needs to be closed. The seal is made of special rubber, which does not slip over time.

Thanks to different profiles, the seal can be matched to almost any gap size.

Application area

- Self-adhesive seals are a fairly simple and easy-to-use popular insulating material used for sound and heat insulation of private and industrial premises. Seals not only prevent drafts from breaking into the room, but also protect against dust and city noise.

- Household self-adhesive seals are designed to seal mating moving surfaces (window frame, sash or door frame, door leaf) various types window and door blocks. Any window or door is a complex structure in which all parts must be tightly fitted and connected to each other, the sealing profile is designed to ensure a tight fit over the long life of the window or door.

Component composition

Our seals are manufactured using EPDM solid rubber, which is a high quality rubber with a unique chemical structure, which makes the seals completely resistant to oxygen and ozone, and as a result, prolongs their service life.EPDM– ethylene propylene diene rubber (a terpolymer of ethylene, propylene and a diene with the remaining unsaturated part of the diene in the side chain), is a tested known material from which resistant, flexible and elastic products are made;

Door seals have a porous structure with closed pores. These rubbers have a number of advantages compared to non-porous rubbers: increased softness, flexibility, high damping properties, elasticity. On the one hand, the seal has an acrylic adhesive covered with protective paper. The adhesive composition also includes synthetic reinforcement fibers to reduce excessive stretching of the sealant.

|

PROPERTIES |

HOUSEHOLD SEALS |

|

Material |

Injected microporous rubber based on EPDM (EPDM) rubber with closed cells and skin on the outer surface |

|

Type of rubber |

EPDM (EPDM) - ethylene-propylene synthetic rubber |

|

Water absorption strength 21± 2°C |

Very good, below 3% ASTM D 1056 |

|

Ozone resistance at concentration 50 +/-5 pphm, 20% elongation, 38°C / 70 h |

Very good, no cracks (2x magnification) according to PN-ISO 1431-2 |

|

Frost resistance |

Very good, no cracks according to Stomil Sanok ZN-66 |

|

Density |

according to ASTM D 1056 |

Types of seals

Household seals

Household seals - self-adhesive seals with dimensions: 9x7, 9x5.5 and 9x4. Winding - in a reel of 100 and 150 meters.

Technical seals

Technical seals - self-adhesive seals with dimensions: 12x10, 14x12. Winding - in a reel of 50 and 40 meters.

Seal properties

Door seals are tape sealing gaskets made of porous rubber. EPDM profile seals (based on ethylene propylene diene monomers) with a layer of tacky reinforced adhesive protected by protective paper.- For sealing and sealing window and door blocks in order to exclude drafts, moisture and dust penetration;

- To create effective heat and sound insulation, eliminate vibration;

- Reduce energy and economic costs - fuel consumption for heating 1 sq. m of living space is reduced by 7%.

- They have excellent adhesion to window and door blocks made of wood, metal and plastic, including painted ones, resistance to high and low temperatures from -55 to +100°C and atmospheric ozone, do not swell under the influence of water and moisture.

- Type E - profile seal in the form of the letter E with dimensions 9 x 4 mm for gaps 2 - 3.5

- Type P - profile seal in the form of the letter P with dimensions 9x5.5 mm for gaps 3 - 5

- Type D - seal profile in the form of the letter D with dimensions 9x7 mm for gaps 3 - 7

The use of seals

- Seals must be applied with inside points of contact between the window and the window frame. Thus, it turns out that when we close the window, the seal covers the gap.

- First, remove the old sealant and clean the surface with fat-free acetone. After the surface has dried, a new seal can be glued. Remove some of the protective paper cover. Pressing the strip firmly from top to bottom, place the material in its place. Without stretching the strips as they are applied, remove the protective paper film. Pay special attention to the corners of the structure. Similarly, profiles are laid on horizontal surfaces. Freshly painted windows must be dried for at least three weeks.

- The material practically does not need maintenance: it is recommended to treat seals with silicone oil, it increases the elasticity of products and helps to extend their service life. The self-adhesive base makes the seals quite easy to install and does not require the cost of additional mounting materials.

- Sometimes in some profiles there is also a third seal circuit, which increases sound insulation and protects against condensate. The installation of the third seal must be carried out carefully, since installation defects can lead to a loose fit of the profiles

- Choose the optimal type of gasket by determining the size of the gaps to be sealed by means of a piece of plasticine wrapped in plastic wrap, laying it between the window frames and the window block or the door leaves and the door frame

- Clean the surfaces of windows and doors from loose paintwork, dirt, traces of fats and oils, degrease with a cotton cloth moistened ethyl alcohol or clean gasoline using a cotton cloth and dry for 15-30 minutes. Note: freshly painted surfaces of windows and doors should be kept for 2 weeks before installation until the paintwork is completely dry; before installing the gasket, strengthen and lubricate window and door hinges;

- Accurately measure the height and width of a window or door with a gasket without stretching it;

- Cut the gasket into pieces of the required length;

- Remove the protective protective paper from a small section of the gasket - 10-15cm;

- Install the gasket on the vertical sections of the window or door, gradually removing the protective protective paper and not stretching the gasket;

- Install the gasket on horizontal sections in the same way, making sure that the corners are well sealed.

The annual economic efficiency E can be calculated using the formula:

E \u003d L x Q x T x P - C,

Where L is the length of the elements of windows and doors not sealed with a gasket, running meters. Q - energy loss per 1 linear meter of windows and doors not sealed with a gasket, kWh (for profile P this value is 48.5) T - duration of the heating season, days (for the middle zone - 215) P - cost of 1 kW x h , rub. C - the cost of the gasket used, rub.

If the installation instructions are followed, the service life of door seals is 7-10 years.

Seal installation method

Proper selection of material, preparation of the installation surface and method of installation have a decisive influence on the strength of the connection. It is recommended to install the seal on smooth surfaces such as:

- surfaces coated with acrylic, phthalic varnishes and other general purpose varnishes, completely dry,

- plastic,

- metal stainless,

- wood, including also stained and impregnated, provided that products are used that give a dry and smooth surface without subsequent wood impregnation, - glass.

The seal is installed at an ambient temperature not lower than +100C. The installation surface must be: dry, smooth, free of contaminants such as dust, chips, mortar and oil. For degreasing the surface, extraction gasoline is used. Immediately before installing the seal, tear off the silicone protective paper. The sealant is adhered to the entire self-adhesive surface without unnecessary stress, for example, sudden changes in the direction of gluing the sealant through its bulge are not allowed.

In case of installation in a corner part, the seal must be cut or trimmed. After preliminary gluing of a sealant it is necessary to press it for the purpose of final sticking. Due to this, the adhesion force of the sealant to the surface is significantly increased. A high adhesive force is obtained only after about 1 hour has elapsed from the installation of the seal. After installing the seal, the elements of the products cannot be cleaned using solvents such as gasoline, acetone, toluene and other organic solvents that are harmful to rubber.

Storage of seals

In a dry and cold room, at a maximum temperature of 25C and a maximum humidity of 70%, in the absence of direct sunlight. The preliminary shelf life is 24 months, counting from the date of production to the date of installation.- The seals are transported by all modes of transport in covered vehicles that protect the seals from mechanical damage, pollution and precipitation, in compliance with the rules for the carriage of goods applicable to this type of transport.

- After transportation and storage at negative temperatures and before use, sealants should be unpacked and used after keeping them at a temperature of (23+-5) °C for at least 24 hours.

- When storing and transporting seals at negative temperatures, it is forbidden to subject them to deformation and shock loads.

- During storage, seals must be protected from direct sunlight, oils and organic solvents.

Video on the use of door seals

Video: how to stick a self-adhesive sealVideo: sealing applications for doors and windows