Classification of cables, wires and cords according to their application with links to examples of specific markings, photographs of cable products

Preface

Cable and wire products are classified based on the use of conductors, their manufacturers, design, and markings. The result will be different pictures. In our opinion, the most acceptable classification method(from the buyer's point of view) is filtering by application cables and wires.

Judge if sorted by manufacturer, then it will be difficult for a person who does not know the nomenclature of a particular plant to understand where to look for the required conductor, much less compare the characteristics of similar products.

When classifying by design, it will be difficult to keep in mind all the design elements to make right choice. In fact, each design is selected based on influencing factors that are determined by the application.

When distributing by markings(for example, alphabetically), any meaningful grouping disappears. In addition, in the marking, each letter has a meaning that relates to the design or application.

But the classification by use or purpose is clear to almost every person who comes across a gasket cable lines or works in logistics. Allows you to find similar cable products in one section of the online store and evaluate them according to technical parameters, and view photographs.

Classification of cables and wires by application

All cable and wire products divided into 6 groups:

- for stationary installation in the air and on the ground;

- for movable connection;

- for overhead power lines;

- for secondary networks - these are multi-core control cables (work in signaling or control networks with low currents);

- for installation and household electrical wiring;

- for specialized operating conditions, from which, due to the variety of brands, we will highlight heat-resistant and fire-resistant conductors.

For stationary installation:

- (trench):

- for voltage up to 1 kV - VBbShv and AVBbShv (copper and aluminum conductor in PVC insulation, armored with steel tapes, in a PVC sheath);

- for voltage 6 kV and higher:

- in paper-impregnated insulation - AABL (aluminum conductors in insulation, armored with steel tapes, in an aluminum protective sheath);

- insulated from cross-linked polyethylene.

Cables with impregnated paper insulation in a lead or aluminum sheath, marked ASB, AABL, AAShv, are laid in trenches. They also produce products with insulation made of cross-linked polyethylene, which make it possible to increase the heating temperature of the current-carrying core, and therefore the current load. The advantages and disadvantages are described in the article about insulated cables SPI.

|

|||

|

VVG cable ng 5x16 for stationary installation in the air |

Cable AVVG 4x120 for stationary gasket in the air |

Cable AVBBShv 4x240 armored Steel tapes For laying in the ground |

Power Armored Copper cable VBBShv 3x25+1x16 for location in the ground |

|

|||

| High voltage cable for laying in the ground APvEgaP |

For mobile connection:

- flexible cable KG is available with 1-5 copper stranded conductors;

- extra flexible cable of the KOG brand with 1 core (used as a welding cable);

- stranded flexible wire RPSh (5-24 copper stranded wires);

- shielded wire RPSHE;

- multifunctional cable H07RN-F in a neoprene sheath.

|

|||

|

Power cable KG 3x25+1x10 with stranded core |

Wire RPSh 10x1.5 for connection movable pantographs |

Cable H07RN-F 5x35 V rubber insulation and neoprene shell |

For overhead power lines (laying in the air between the supports):

- insulated self-supporting wire of the SIP brand;

- bare wires A and AC (the first wire is aluminum, the second is aluminum with a steel core).

For secondary networks or control cables are designed for monitoring and control systems, alarms and interlocks, therefore they contain 4-37 cores with a cross-section of 1-4 mm 2:

- KVVG (for single gasket);

- KVVGE (protected by a screen for a single location);

- KVVGng (reduced flammability version for joint installation);

- KVVGng-LS (reduced flammability design with low gas and smoke emission during forced combustion for electrical systems in buildings with large crowds of people);

- KVVGEng (shielded conductor for group installation);

- KVVGEng-LS (with a screen of reduced fire hazard);

- AKVVG (aluminum for single location);

- AKVBBShv (armored control for laying in the ground).

| Control cable KVVG 7x1.5 for secondary networks in PVC insulation and sheath |

Shielded control cable KVVGEng 27x2.5 in low flammability version |

Aluminum control cable brand AKVVG 10x2.5 |

For installation and household electrical wiring:

- stationary and movable (in a shell):

- 2-5 core wire PVS;

- 2 and 3 core SHVVP cord;

- only stationary:

- single-core:

- single-wire copper wire PV1;

- its aluminum analogue is the automatic reclosure wire;

- stranded flexible wire PV3;

- 2 and 3 cores:

- copper PPV;

- aluminum APPV.

- single-core:

For electrical wiring in houses, apartments and cottages Suitable conductors produced (more details for an intelligent choice):

- according to the household standard GOST 7399 - PVS and ShVVP;

- according to GOST 6323 standard - PPV and APPV;

- according to the industrial standard - VVG and its derivatives

|

|

|

|

| Wire PVS 5x4 for household electrical wiring and mobile accession |

ShVVP cord 3x2.5 for laying under the plaster in houses, apartments, dachas |

Flexible installation wire PV3 4 |

Rigid copper wire PV1 2.5 In PVC insulation |

For specialized installation conditions:

- heat-resistant (long-term use at elevated temperatures):

- PVKV - organosilicon insulation;

- PRKA - organosilicon insulating and protective shell of increased hardness;

- RKGM - silicone insulation + fiberglass protection;

- PET-155 - enameled wires for creating windings of electric motors;

- fire-resistant (functional in case of fire for 30 or 90 minutes):

- (N)HXH - power supply for emergency systems (elevators, ventilation, lighting);

- JE-H(St)H…Bd - for fire safety systems;

- transport:

- aviation:

- BPVL - copper, resistant to noise, vibration, single and multiple impacts;

- BPVLE - shielded;

- BPVLA - aluminum;

- PTL-200 and PTLE-200 - in addition to vibration and shock loads, it is resistant to temperatures up to +200°C;

- mine KGESH - for movable connection, resistant to abrasion from rocks, flexible;

- marine NRShM - resistance to salt and fresh water, resists the effects of diesel fuel and oils;

- excavator KGE - for connecting a moving earthmoving machine with an overhead line for a voltage of 6 kV;

- railway PPSRVM - for rolling stock (electric locomotives, ground passenger electrified transport) for voltages of 660 and 3000 volts;

- aviation:

- other special:

- TPPep - telephone cables with 10, 20, 30, 50, 100 or 200 pairs of cores;

- PShch - for brushes of electric machines.

| Heat-resistant wire RKGM for laying at temperatures up to 180°C |

PET-155 enamel wire for winding electric motors |

Heat-resistant wire PVKV brand | Photo of heat-resistant PAL wire |

For laying in water

withstands vibrations and shocks

Telephone cable cross-section

TPPep with 50 pairs

for rolling stock

PPSRVM 95

Electrical energy transmission

To understand the use of each conductor, let's trace the path of electrical energy from a source (for example, nuclear power plant) to the consumer (a specific engine, machine, household electrical appliance, and so on).

Scale of electrical networks:

- trunk networks - a hierarchically higher network connecting powerful power plants with a large population of consumers (for example, regions of the country) with high level voltages 110, 150, 220 or 330 kV (depending on the territory of the country);

- regional networks - a regional-scale network, which is powered from the main system through a step-down substation, has medium-level voltages of 30, 35, 45, 60 kV;

- distribution networks - serve to supply medium and small consumers (plants, factories, towns, villages), often with voltages of 6 and 10 kV;

- internal networks- transportation of electricity in a limited space (within a city district, on the territory of an industrial enterprise) with voltage up to 1000 volts;

- electrical wiring - hierarchical lower network, used for transmitting electricity in a building, apartment, house (understood as an internal network).

For high-voltage lines, the use of a three-phase system is typical alternating current. Three conductors are used for three phases, which are accompanied by a fourth grounding conductor PEN. In household and industrial networks, where it is not necessary to transmit large powers, a two-wire network is used (phase + neutral working wire N). In fact, the three-phase network is divided into three two-wire networks. According to modern electrical safety requirements, it is necessary to introduce an additional protective conductor (PE), then the network takes the form: phase + N + PE.

From the power plant, energy is carried through high-voltage power lines at voltages in excess of 15,000 volts. When approaching the city, a step-down transformer substation is installed, from which high-voltage lines with a voltage of 6,000 or 10,000 volts also emanate. Already in the city itself, in front of a large industrial facility or in front of a group of residential buildings, the next transformer substation is installed, which reduces the voltage to 220, 380 or 660 volts. A large facility may have networks with different voltages, mostly no more than 660 volts.

The meaning of high voltage lines consists of one thing - in this way minimal electrical losses are achieved. Losses are directly proportional to electrical resistance and inversely proportional to the square of the current, that is, they do not depend on voltage.

Since electrical resistance can be influenced up to a certain limit, it remains to reduce the current flow. Electrical resistance mainly depends on the material of the conductive elements (copper and aluminum are most often used). The transmitted power is equal to the product of voltage (U) and current (I). Therefore, the same power can be conveyed by different combinations of arguments:

P=U∙I

P = 220 V ∙ 100 A = 22 kW (large losses);

P = 6000 V ∙ 0.37 A ≈ 22 kW (losses are 4 orders of magnitude less).

The transmission and distribution of electrical energy is impossible without wires and cables. In addition, wires are also used to assemble control, protection and automation circuits. Let's look at how they differ and are classified depending on their design and purpose.

Wire classification

The first classification feature by which wires are distinguished is core material. They come in copper and aluminum. In addition, copper wires are either rigid or flexible. The hard core has a solid, round cross-section. Starting from a certain cross-section, rigid conductors are made from round wires. This is due to the fact that it is impossible to bend a core of such a cross-section during installation.

Highly flexible wires consist of thin copper wires gathered into a bundle. Their advantage is that they can be tightly packed in a cable channel or collected in a bundle. In addition, they are convenient to use for connecting elements located on cabinet doors or control panels. Connecting flexible conductors to the terminals of electrical equipment is possible only with the use of special tips. Although some of the devices support direct connection of flexible wires, the use of ferrules allows you to disconnect and reconnect them with maximum convenience. In addition, during assembly there is no need to ensure that none of the wires falls out of the bundle and is not shorted to an adjacent terminal.

Aluminum conductors are not made flexible due to the excessive brittleness of aluminum. For the same reasons, wires with a cross-section below 1 mm 2 are not produced.

Further differences relate to the insulation material covering the live parts.

In addition, the wires are made multi-core. In this case, their characteristics include the number of cores (two, three or four) and the material of the shell covering the structure. The sheath may be absent, as in a wire, commonly called “noodles”. This category also includes cords that are characterized by increased flexibility of both core material and insulation and are intended for connecting portable electrical receivers and household appliances.

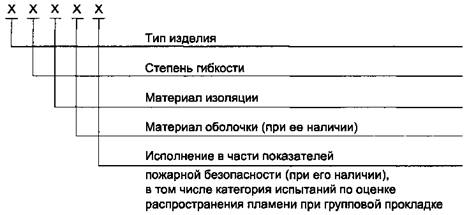

All listed parameters are indicated in the wire type. It is built according to the principle shown in the figure.

Labeling begins with an indication core material. For copper, this element is skipped, and for aluminum, the letter “A” is placed at the beginning of the code.

The product type may contain letters deciphered in the table.

|

Letter "product type" |

Decoding |

| P | the wire |

| installation wire | |

| PB | household wire |

| Sh | cord |

The most common insulation materials: polyvinyl chloride (B) and rubber (R). The same applies to the shell material.

Some manufacturers deviate from generally accepted labeling rules. For example, a wire with a single core in vinyl insulation is sometimes designated as PV-1, and flexible – PV-3.

Cable classification

Cables differ in the material of the current-carrying cores. Copper is an expensive material, so sometimes cables with aluminum conductors are deliberately used to reduce costs. The disadvantage of this method is the increase in the cross-section of the conductors, since aluminum has lower electrical conductivity compared to copper. In addition, it oxidizes more intensively and is softer, which leads to the need to stabilize bolted connections, otherwise the contacts will weaken over time. Due to the risk of creating a galvanic couple between copper and aluminum, connection to copper terminals of electrical devices is possible only with the use of special lubricants. Manufacturers of modern electrical equipment, in order to ensure the ability to connect cores made of various materials to it, make contact pads anodized or tinned.

Cables, like wires, are available with flexible cores and monocore. To save space inside the cable, large cross-section cores are made in sectors. The sector cores themselves are monolithic or consist of a group of wires tightly laid side by side.

The use of cables and wires with aluminum conductors with a cross-section below 16 mm 2 for the installation of electrical wiring in household facilities is prohibited by the PUE.

The cable cores have insulation that completely follows their shape. The most common material from which core insulation is made is polyvinyl chloride(PVC), called vinyl for short. Cables with insulation from rubber. They have great flexibility and are used in devices whose cables move during operation. They are used to power and control crane beams, connect grab, gantry and bridge cranes. Rubber in the open air becomes woody, cracks and breaks. It dries even under the influence elevated temperature. Therefore, the insulation of rubber cores after cutting the cable is additionally protected by installing PVC or heat-shrinkable tubes.

Previously, they were used in electrical installations cables with impregnated paper insulation. Special cable paper is wound onto the cores in several layers and then impregnated with a special compound. These cables were intended for use in electrical installations up to and above 1000 V, but had a number of disadvantages. The mass with which the cables were impregnated came out through the cracks in the end couplings and holes that appeared as a result of damage to the cables, and moisture from the air or ground took its place. As a result, the insulation deteriorated and the cable failed.

In addition, the implementation of connecting and end couplings on these lines took a long time and required the professionalism of workers.

These cables are being replaced by products made from cross-linked polyethylene. They do not have the main disadvantages of oil-impregnated cables, and the technology for installing couplings on them is much simpler.

The cable minimally includes at least one common sheath for the cores - waist insulation. It is usually made from the same material as the core insulation. It can be wound over it armor made of steel or galvanized tapes, and then another insulating shell. The cable armor must be connected to the ground loop.

It is worth highlighting control cables. If power cables include from three to five cores, and their cross-section varies from 1.5 to 240 mm 2, then the number of cores in the control cable is measured in tens. The range of their sections is not wide: from 1.0 to 4.0 mm 2.

They are also sometimes equipped with an analogue of armor - screen, consisting either of woven thin copper wires (like antenna cables old model), or from copper or aluminum tapes. The need for screens is dictated by the development of microprocessor devices in control circuits that are sensitive to electromagnetic interference. The cable shields are connected to the PE bus, usually only on one side.

Cable markings

A letter code is used to mark cables. It indicates full information about the materials from which the cable is made, its purpose and design. From the markings you can find out exactly what shells, screens or armor are contained inside the product. The order in which information is decrypted is shown in the table.

| Purpose | Examples | |

| Core material | no letter | Copper |

| A | Aluminum | |

| Additional metal shell | A | Aluminum |

| WITH | Lead | |

| Purpose | TO | Control |

| Core insulation material | IN | Polyvinyl chloride |

| R | Rubber | |

| HP | ||

| Shell material | IN | Polyvinyl chloride |

| R | Rubber | |

| HP | Flame retardant rubber | |

| Availability of reservation | B | Two layers of tapes |

| Bn | The tapes have a protective non-flammable sheath | |

| No protective cover | G | "naked" |

Cables with cross-linked polyethylene insulation are marked according to special rules.

Among the most popular in Lately species cable products

can be called VVG cable and its modifications.

VVG denotes a power cable with TPG insulation made of PVC, a sheath (cambric) made of PVC, copper core material, which does not have external protection (Fig. 1).

Rice. 1. VVG cable

Used for transmission and distribution electric current, operating voltage - 660-1000 V, frequency - 50 Hz. The number of cores can vary from 1 to 5. Cross-section - from 1.5 to 240 mm2. In domestic conditions, a cable with a cross-section of 1.5-6 mm2 is used; in the construction of a private house, a cable with a cross-section of up to 16 mm2 is used. The cores can be either single- or multi-wire (Fig. 2). There are no restrictions - you can also install a cable with a cross-section of 10 mm2 in an apartment.

Rice. 2. VVG cable cross-section

Can be used over a wide temperature range: from -50 to + 50 °C. Withstands humidity up to 98% at temperatures up to +40 °C. The cable is strong enough to withstand tearing and bending, and is resistant to aggressive chemicals. When installing, remember that each cable or wire has a certain bending radius. This means that for a rotation of 90 °C in the case of VVG, the bending radius must be at least 10 diameters of the cable section. In the case of a flat cable or wire, the width of the plane is considered.

The outer shell is usually black, although sometimes white can be found. Does not spread fire. TPG insulation is marked in various colors: blue, yellow-green, brown, white with a blue stripe, red and black. The cable is packaged in coils of 100 and 200 m. Sometimes other sizes are also found.

Varieties of VVG:

AVVG- the same characteristics, only instead of a copper core, aluminum is used (Fig. 3);

Rice. 3. AVVG cable

VVGng- cambric with increased non-flammability (Fig. 4);

Rice. 4. Cable VVGng LS

VVGp- the most common type, the cable cross-section is not round, but flat;

VVGz- the space between the TPG insulation and the cambric is filled with PVC strands or a rubber mixture.

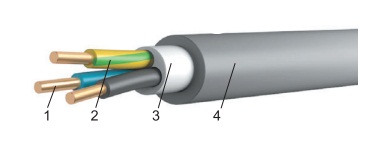

NYM power cable does not have Russian decryption letter designation. This is a copper power cable with TPZh PVC insulation, the outer sheath is made of non-flammable PVC. Between the layers of insulation there is a filler in the form of coated rubber, which gives the cable increased strength and heat resistance. The cores are multi-wire, always copper (Fig. 5).

Rice. 5. NYM cable: 1 - copper core; 2 - PVC shell; 3 - longitudinal non-flammable sealing; 4 - PVC insulation

Number of cores - from 2 to 5, cross-section - from 1.5 to 16 mm2. Designed for carrying out lighting and power networks with a voltage of 660 V. It has high moisture and heat resistance. Can be used for outdoor installation. Operating temperature range - from -40 to +70 °C.

Disadvantage: does not withstand sunlight well, so the cable must be covered. Compared to VVG of any type, it is more durable and easy to use. However, it only comes with a round cross-section (it is inconvenient to install in plaster or concrete) and is significantly more expensive than VVG. Bending radius - 4 cable cross-section diameters.

It is explained very simply - the cable is flexible. This is a conductor with an operating alternating voltage of up to 660 V, a frequency of up to 400 Hz, or a direct voltage of 1000 V (Fig. 6).

Rice. 6. KG cable

Copper conductors, flexible or highly flexible. Their number varies from 1 to 6. TPG insulation is rubber, the outer shell is made of the same material. Operating temperature range - from -60 to +50 °C. The cable is mainly used to connect various portable devices. Most often these are welding machines, generators, heat guns, etc.

There is a type of KGng with non-combustible insulation.

KG has proven itself excellently as a cable that operates under almost any outdoor conditions. At a construction site, it is simply irreplaceable for pulling power lines. Although some original people, attracted by the flexibility and reliability of the KG, install it as home wiring.

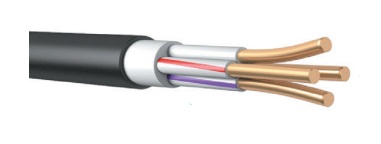

Cable VBBShv- armored power cable with copper conductors (Fig. 7).

Rice. 7. Cable VBBShv

The latter can be either single-wire or multi-wire. Number of cores - from 1 to 5. Section - from 1.5 mm2 to 240 mm2. TPG insulation, outer shell, space between the insulation and the cambric - PVC is used in all these places. Then comes the armor of two tapes, wound in such a way that the outer one overlaps the boundaries of the turns of the lower one. On top of the armor, the cable is enclosed in a protective PVC hose, and the VBBShvng modification uses this material of reduced flammability.

VBBSHv designed for alternating rated voltages of 660 and 1000 V. Single-core modifications are used to conduct direct current. Installed in pipes, ground and outdoors with protection from the sun. Operating temperature range - from -50 to +50 °C. Moisture-resistant: at a temperature of +35 °C it can withstand 98% humidity. It is used when conducting electricity for stationary installations, as well as supplying electricity to detached objects. Bending radius is at least 10 cable cross-section diameters. VBBSHv is perfect for underground supply of electricity to a separate building.

Modifications:

AVBBSHv- cable with aluminum core;

VBBShvng- non-flammable cable;

VBBShvng-LS- non-flammable cable with low gas and smoke emission at elevated temperatures.

For each type of wiring it is necessary to select the correct wire. When choosing a wire, you need to take into account such points as the purpose of its use, the type of sheath, as well as the strength of the current that it will conduct. The current strength is directly proportional to the thickness of the wire.

Single-core and stranded wires

The wire diameter is classified by gauge. In this case, the quantities are inversely proportional, i.e. The smaller the cable gauge number, respectively, the larger the core diameter. The larger the gauge of the wire, the greater the number of cores in it. This makes multi-core wires easier to bend and therefore easier to install.

Types of stranded wires. Cables for connecting home electrical wiring and the main grounding line.

Single-core and stranded wires.

The most common single- and multi-core wires and their load limits.

In a residential building, as a rule, electrical wiring with non-metallic insulation is used. This wire contains two conductors in a plastic insulating winding and one grounding conductor. All these wires are placed in a plastic sheath.

These parameters are easily read in the name of the wire itself.

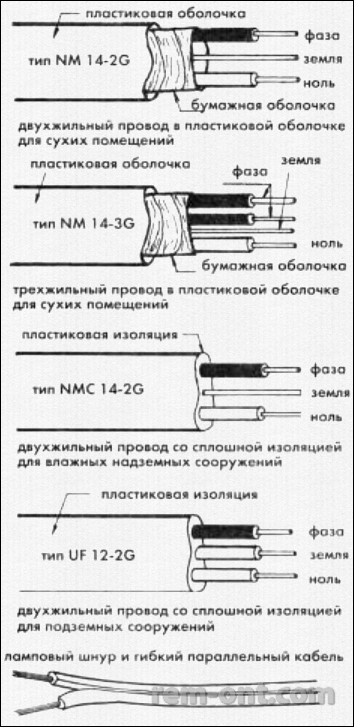

The main types of wires for electrical wiring:

- two-core wire in a plastic sheath for dry rooms;

- two-core wire with continuous insulation for above-ground structures exposed to moisture;

- two-core wire with continuous insulation for underground structures;

- lamp cord;

- flexible parallel cable.

Types of wires for home electrical wiring.The structure of an industrial cable used in harsh environments, as well as an auxiliary cable. Fiberglass wrapped in paper is used to separate the wires.

Cable structure:

- phase;

- zero;

- Earth;

- paper shell;

- plastic shell.

For example, wire 14-2 has two cores, and if it contains grounding, then the prefix “with grounding” is added to the name. Often, in a residential building, wiring is made of single-core wires (14-10 numbers). The table below lists copper, aluminum, and copper-clad aluminum wires and the amperage that each can carry.

Types of wires and their electrical current carrying capacity.

| Amps | ||

| Wire size | Copper Wire Size | Size of aluminum wire or the same wire covered with copper |

| 18 | 7 | |

| 16 | 10 | |

| 14 | 15 | |

| 12 | 20 | 15 |

| 10 | 30 | 25 |

| 8 | 40 | 30 |

| 6 | 55 | 40 |

| 4 | 70 | 55 |

| 3 | 80 | 65 |

| 2 | 95 | 75 |

| 1 | 110 | 85 |

| 0 | 125 | 100 |

Types of Electrical Cables

The following types of wires are used in wiring:

- NM – for dry environment;

- NMC – is used at high external humidity, usually in above-ground structures;

- UF - waterproof wire is used in underground structures.

Some popular types of electrical cables include armored and waterproof.

Quite often a flexible double wire and a lamp cord are used. The lamp cord has two cores, which are in one plastic sheath, and also has a small diameter. The gauge of this cord can be from 18 to 10. This cord belongs to class C. The marked lamp cord has grooves or ribs on the side where the phase is located.

Photo of a regular lamp cord.

Among other wires, flexible double wire is quite common for lamps, refrigerators, radios, etc. This type of wire is classified into types such as SP, SPE and SPT, as well as by number and type of outer sheath. SP and SPT have a heat-curing plastic sheath, while SPE type wire has a heat-curing elastomer sheath.

Wire diameters

Each type varies in wire diameter. So, for example, the SP-1 wire has 18 or 20 gauge wire, and the SP-2 has 16 or 18 gauge wire. Three-core wires have 18 to 10 gauge wires. Since the gauge of three-wire wires is generally lower, they are used for electrical appliances such as room air conditioners or refrigerators.

Three-core AC cable SP-8.1 made of pure oxygen-free copper.

Heavy-duty cord is used for using power tools. This type of cable has three stranded wires, which are insulated with plastic and housed in a durable plastic sheath. These wires are separated by several layers of fiberglass, which is wrapped in insulating paper. Such cables are marked SE, SEO, SEOW and SEOO. The suffix SJ denotes auxiliary cables. A cord intended for a computer, for example, is branded SJT.

An example of a protected SEOW brand electrical cable from Coleman Cable.

The most common cables in older homes are BX armored grades. This type of cable consists of two insulated wires wrapped in paper and a bare ground wire in a flexible metal sheath. Today, such cables are used in places with a high probability of damage and additional protection is required. This cable, compared to “plastic” cables, is less easy to cut and strip and is more difficult to connect.

Wiring protected metal pipe and armored cable type AC. Elements:

- spring flexible steel shell;

- ground, phase, zero;

- paper insulation;

- rigid metal pipe.

There are also plastic armored cables.

The protective casing for electrical wiring is rigid metal or plastic pipe, in which the wires are laid. The pipe itself is just a cover. As a rule, the pipe is installed first and only then the wires are pulled through it.

Typically, a protective pipe is installed in areas where serious protection from external influences, such as moisture and possible damage, is required. A striking example of the use of a protective casing (pipe) can be the path from the input to the meter.

Plastic casing with metal braiding that protects electrical cables.

If necessary, the pipe can be connected with threaded couplings and bends at turns. If the pipe walls are thin enough, it can be bent at a large angle. Electrical codes define acceptable bending angles.

Aluminum wires

Aluminum wires were used in some houses built back in the 40s. last century. An aluminum wire should be twice as thick as a copper wire (at the same current strength), since aluminum has greater property electrical resistance than copper. When selecting the gauge of aluminum wire, it is always recommended that you refer to your local code. You need to find out whether your sockets and switches can be used with aluminum wiring.

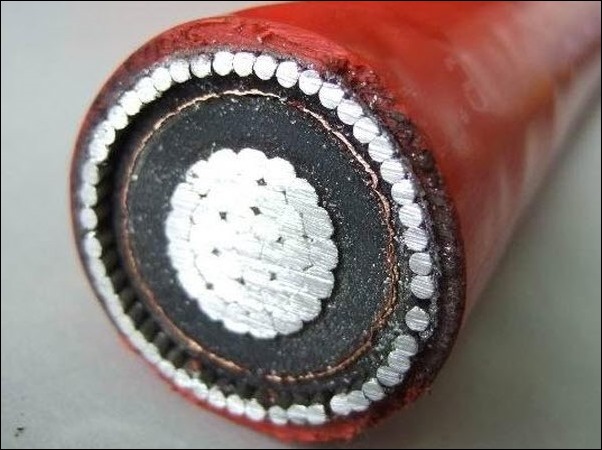

Aluminum insulated XLPE power cable.

In aluminum wire wiring, screw connections are used rather than clamping ones. Lamps, sockets and other electrical fittings can be used with aluminum wiring, provided they do not have special markings such as “CO/ALR”. If the socket or switch heats up, the lights flicker, you smell burnt insulation, or other bad signs, call an electrician immediately, as serious troubles may await you.

Aluminum electrical wiring can fail without such obvious signs. Don’t even think about doing it yourself and trying to repair the electrical wiring yourself.

Aluminum electrical cables AI ACSR in a protective sheath of neoprene.

In order to determine what metal your electrical wiring is made of, you need to look at the exposed section of the wire. It can be found either in the attic or basement. As a last resort, open a small section of the wiring yourself. After a certain distance, the aluminum wire is marked “AL” or “Aluminum”.

Try whenever possible to replace aluminum wiring with copper, as only a professional can save it. After all, only he knows what types of connections are used in certain cases. Just make sure the professional is sober.

How to work with wires correctly

Before connecting the wire, you need to measure the required length, cut and strip the insulation from the end of the wire. Several types of tools are used for this work.

Tools you can’t do without when doing electrical work:

- long-nose pliers, also known as round-nose pliers;

- regular pliers;

- wire cutters

When purchasing such a tool, make sure that its handles are insulated as required, otherwise you will physically not be able to return the product later.

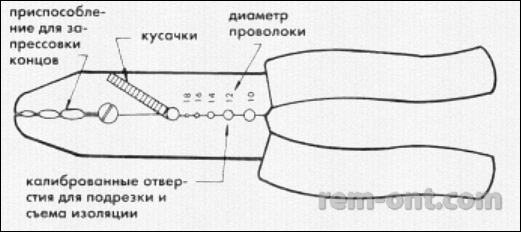

Photo of a tool for stripping electrical wire from insulation.

Pliers are very convenient for working with large wires such as the Romex cable. Round-nose pliers (also known as long-nose pliers) have small nippers and are useful for rolling the bare end into a ring. With wire cutters you can cut small diameter wires even in the most difficult to reach places, which is undoubtedly an advantage over other tools. However, the title of universal and perhaps most useful tool goes to the insulation stripper.

Typical insulation stripper. Components:

- openings for pressing ends;

- wire cutters;

- you can choose the wire diameter;

- calibrated holes for trimming and removing insulation.

They can determine the gauge of the wire, remove the insulation, press the ends together, make a ring at the end, and many other useful things. In general, the tool is suitable for both inexperienced housewives and professional electricians.

Cutting ends

In order to connect a wire to a fitting or to another wire (twist), you must first expose its end by removing the insulation. Use special tools for this purpose, since there are a great many of them. During work, do not cut the wire under any circumstances, otherwise you will significantly reduce its strength and current carrying capacity, since the cross-section will decrease. When working with multi-core wire, it is necessary that all the wires remain intact and unharmed.

With the help of a specialized stripper, insulation can be removed in a matter of seconds.

When working with a cable in plastic protection, the first thing you need to do is expose the core wires by cutting off the sheath from it. For this purpose, use a sharp knife. With the cable on a hard surface, make a cut at the end along it to the length you want to expose. Try not to damage the insulating sheath of the core wires. If you still make such a mistake, cut off the damaged piece of cable completely and start the operation again.

Removing the sheath from the cable.

- Place the cable on a hard surface and carefully cut the sheath down the center.

- Pull aside and cut off the sheath without damaging the wires.

Essential elements:

- plastic sheathed cable;

- ordinary tool knife;

- plastic shell;

- Use a knife or scissors to cut the shell.

When removing insulation from a core wire, you can use a pocket knife. Make careful cuts without touching the wire itself, and begin to cut the insulating sheath with smooth movements away from you so that the result is a cone. Do not attempt to cut perpendicular to the wire as you may damage the integrity of the metal core (wire).

Examples of how to correctly and incorrectly remove insulation from a conductor.

- You need to be very careful when removing the insulation with a knife.

- See how to remove it correctly.

- You cannot cut the insulation perpendicularly in copper wire - you risk cutting it.

- If the wire is cut, its transmission capacity will decrease significantly.

The insulation can also be removed using a miracle stripper. To do this, determine a calibrated hole on the tool that corresponds to the diameter of the wire, place the wire in this very hole, clamp it and make a 360-degree turn (not Celsius) around the wire with the puller. Having thus cut off the insulation, pull it off the wire.

Removing insulation using a universal stripper.

- Place the wire in a hole of suitable diameter.

- Squeeze the handles and wrap the puller 360 degrees around the wire.

- The stripper cuts the insulation and preserves the wire itself.

Connecting the wire to the fittings

To connect a wire to an electrical fixture, you need to clamp it with a screw or insert it into a clamping contact. In the case of a screw, the following procedure must be followed.

First, strip the insulation from the end of the wire, three-quarters of the way around the circumference of the screw. Then twist the bare end of the wire into a loop using round-nose pliers (also known as long-nose pliers). And finally, put the loop you made on the screw so that when screwed clockwise, the wire wraps around it.

![]()

Make a loop three-quarters of the way around the screw.

Place the loop on the threaded surface of the screw, with the free part of the loop facing clockwise in the direction of tightening.

Tighten the screw so that the side of the hinge is in contact with the plane of the plate.

If you need to connect a wire to an electrical fixture using a clamp terminal, proceed as follows. Strip the end (of course the wire) to the length of the gauge, which is usually indicated on the side of the fittings, and insert it into the hole in the clamping contact.

![]()

Connecting the wire to the clamp contact.

- Insert the bare end into the hole.

- Press to pull the end out.

- Insert the end of the screwdriver to open the clamp.

- In this case, the end of the wire must be cleared of insulation in advance.

The end will clamp automatically in this hole. If you suddenly need to release the clamped end, insert a screwdriver into the slot located near the hole. On the reverse side of the switch there is such a thing as a groove-caliber. It shows the required length of the bare end, which is inserted into the clamp.

Video on connecting wires in a junction box

This video demonstrates visual techniques for connecting drives in a distribution box and demonstrates how disconnection and welding of various twisted electrical wiring is carried out.

Twisting wires

Twist the ends of the wire, first exposing them to a length of about 16 mm. Then place a special cap on the twisted ends, rotating it in the same direction along which the exposed wires were twisted. If the cap does not completely cover the exposed wires, trim them so that it does.

An example of twisting a three-core cable.

Specialized pliers for twisting wires.

For reliability, you can additionally wrap insulating tape the junction of the cap with the wires, thus better securing it. It is advisable not to spare the tape and cover the joint with two layers.

Twisting the wires and covering them with a cap.

- Place the ends of the wires against each other and twist clockwise.

- Place the cap on the twist and turn it clockwise.

- Secure the cap to the wires with several layers of insulating tape.

In exactly the same way, stranded and solid wires are connected.

Classic multi-core cable with copper braiding and plastic protective sheath.

However, stranded wires with a small diameter cannot be connected by twisting. As a rule, these are lamp cords and cords of low-power consumers. Such cords must remain intact and if this integrity is damaged, the entire cord must be replaced.