The desire to save money when connecting various household appliances or laying electrical wiring often leads to very sad consequences. The question arises: how to ensure the normal and safe functioning of the system, but at the same time avoid unnecessary expenses? VVG cable ng LS is one of best options for use at home and is very popular among electricians. Why?

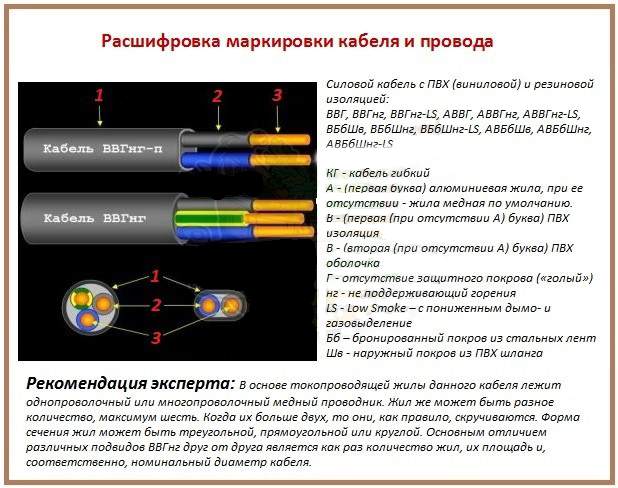

Explanation of markings

Before describing the properties of this conductor or its specifications, you need to figure out what this abbreviation actually means and the numbers that follow it. Otherwise, it is not clear what qualities, for example, a VVGng LS 5x16 cable has, and how it differs from a VVGng LS 5x2.5 cable?

WITH letter designations everything is quite simple:

- The absence of the letter "A" at the beginning indicates that the cable is copper.

- The two letters “B” indicate that both shells, outer and inner, are made of polyvinyl chloride.

- The symbol "G" indicates bare wire. It should not be used in underground installations or where there is a risk of physical damage without additional protection.

- “Ng” - the property of not supporting combustion, the addition “LS” indicates that during fire the smoke emission will be minimal. The abbreviation "LS" means "low smoke", that is, "little smoke".

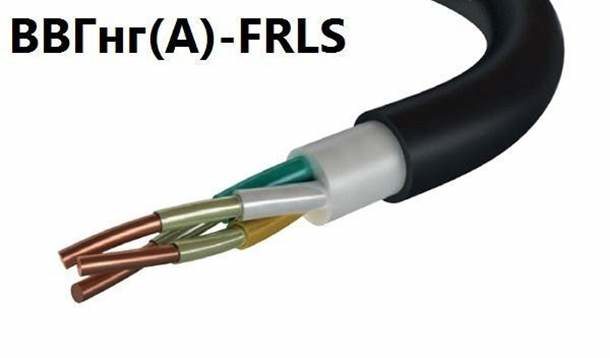

There may be more symbols, for example, cable VVGng and frLS 3x1.5. The decryption in this case will be as follows:

- The symbol “a” indicates that the wire can be used for group installation.

- The abbreviation “fr” means the presence of additional fire protection due to mica materials.

- There may also be an additional letter “p”. The peculiarity of such a wire is the flat arrangement of the cores in the wire.

The numbers after the letter code indicate the number of conductive wires and their cross-section.

For example, the VVGng LS 4x25 cable has 4 cores, each with a cross-section of 25 mm2, and the VVG PNG and LS 3x1.5 cable has 3 1.5 mm2 each, and the VVGng LS 5x16 cable has 5 cores with a cross-section of 16 mm2.

Wire design

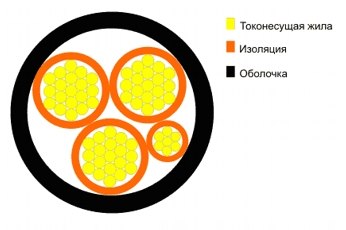

- According to their shape, the veins are sectoral or round.

- Each core has individual polyvinyl chloride insulation. Its thickness must be at least 0.3 mm. The insulation must fill all spaces between the cores, leaving no voids.

- The cores can be made in the form of a single wire or twisted from several. In the latter case (this is more typical for sectoral wires), manufacturers can abandon individual polyvinyl chloride insulation by covering the overlapped twist with a layer of thermally bonded fabric or polyethylene terephthalate film.

- As a rule, current-carrying conductors are marked different colors for convenience during installation work.

- The cable may have grounding and neutral conductors. They may differ not only in color (grounding - yellow-green, neutral - blue), but also in cross-sectional area. In this case, this is also displayed in the wire marking, for example, VVGng LS 5x10 + 1x5(N).

The size of the cross-section of the conductors directly depends on the expected load: the thicker the conductor, the greater the power of current that can be transmitted through it. Accordingly, the weight of the wire increases. So, a kilometer of cable (and it is in these units that the weight for this product is calculated) VVGng LS 5x10 will pull 756 kg, and the same section of VVGng LS 5x16 cable will already weigh 1103 kg. More accurate data is provided in special tables.

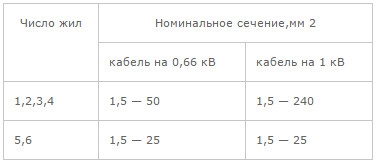

Products of this type are available for voltages of 660 V and 1000 V at standard frequency alternating current 50 Hz. The wires in this case will differ in the thickness of the insulating layers, and therefore in diameter. Thus, the VVGng LS 3x2.5 cable for 660 V has a nominal outer diameter of 9.3 mm, and the same cable, but designed for 1000 V, has a nominal outer diameter of 10.2 mm.

Application

Power cable, for example, VVGng and LS 3x1.5, is intended for installation indoors, where the presence of people is implied. This is facilitated by its ability not to support combustion and release minimal amount toxic substances when heated. These could be residential buildings, offices, shops and so on.

Wires of this type are laid at a temperature not lower than -15˚С, otherwise additional heating will be required.

The operating temperature range of the VVGng LS cable is from -30˚С to +50˚С. The wire does not lose its properties for a long time even if it heats up to +70˚С during operation, and begins to burn only at +400˚С.

During installation, the minimum bending radius of the conductor should not be less than 7–10 of its outer diameters.

The leading manufacturers of VVGng LS cables in Russia are domestic companies:

- Moscow JSC "Moskabelmet";

- St. Petersburg CJSC “Sevkabel”;

- Podolsk JSC NP Podolskkabel;

- Smolensk LLC "Concord".

Subject to operating conditions and periodic inspection of the insulation, manufacturers promise a 30-year period of normal use of the cable and give a five-year guarantee from the date of installation of the wiring.

Wire and cable VVGng LS is the top of the family cable products with the abbreviation VVG, the secret of his privilege is the postscript LS, what it indicates and what it hides will be discussed in detail in this article.

Smoke in premises is considered the most important factor increasing the risk of negative consequences in the event of a fire. In case of fire at industrial facilities and large public buildings, cable routes become one of the main sources of smoke. The sad experience of the Ostankino TV tower, the Manege and other disasters of the last decade only confirmed this truth.

Currently, technical regulation documents strictly regulate the types of cable products that can be used for group installation inside public and industrial premises (GOST R 5315-2009). Here, in addition to the condition of non-propagation of combustion (-ng), one of the mandatory requirements was low smoke and gas emissions during combustion or smoldering of the cable.

LS designation, order of assignment

The decoding of VVGng LS is as follows:

- There is no letter A at the beginning of the marking, which means the cable is copper;

- B - the outer insulating layer consists of PVC insulation;

- B - core insulation consists of PVC insulation;

- ng - does not spread fire when laid individually or in groups;

- LS- L ow S moke (translated from English as light smoke)

In the VVGng (..)-LS marking, after the category separated by a hyphen there is the designation LS, indicating low smoke gas emission ( L ow S mock). Of course, such an index can be assigned to a cable only if it is successfully tested for such an indicator. The standard procedure for testing for smoke formation during combustion and smoldering, a description of the installation, etc. are given in GOST R IEC 61034 -1(2)-2005.

The principle of the test is to measure the transparency of the air in the chamber with the cable before and after combustion. The smoke generated as a result of combustion of the sample reduces the light transmission of the volume, which is recorded by instruments. The result of the test will be the ratio of light transmittance before and after the experiment, expressed as a percentage. In accordance with GOST R 53769-2010, the cable is considered to have successfully passed the test if smoke reduced transparency by no more than 40%. In this case, the manufacturer has the right to put the LS index in the labeling.

Low smoke emission cable insulation

For the production of VVGng LS cable, PVC compounds of reduced fire hazard are required, and in contact with fire they should not produce a large amount of smoke. In addition, it is required that the smoke be minimally toxic (toxicity indicator - no more than 40 mg/m 3 according to GOST R 53769-2010).

The task is complex, but it was successfully solved by selecting special additives - antipyrines and additives. Today, such plastic compounds are produced both in Russia and abroad. Domestic manufacturers have registered several specifications, for example TU 2246-001-25795756-2009, and use them to produce plastic compounds specialized for core insulation, internal filling and outer sheath (grades PPI 30-30, PPV-28, PPO30-35, respectively).

VVGng LS cable structure

The composition and arrangement of the elements of the VVGng(..)-LS cable is no different from its counterparts - cables with copper conductors, with PVC insulation and sheath according to GOSTR 53769-2010. The external resemblance is clearly visible in the image shown in this section.

The VVGng(..)-LS cable can be round or flat, the maximum number of cores is five. The cores themselves can be single-wire or multi-wire, round or sector. The nominal values of cross-sectional areas are selected from a standard series that is common to all.

Cable VVGng LS technical characteristics

Since the characteristics of the entire family of cables with PVC insulation of cores and sheaths are standardized by one standard GOSTR 53769-2010, they vary only within small limits between different manufacturers. The standard does not introduce separate indicators for the cross-sections and shape of cores, the thickness of conductor insulation and sheath, electrical resistance etc. for cables with insulation made of plastic compounds with reduced smoke generation. They go along with the entire family of PVC plastics. Separate values are indicated for insulation made of cross-linked polyethylene, etc.

GOST 53769-2010 provides for -LS products some difference in minimum tensile strength; it may be less than that of VVG, but does not differ from VVGng. Therefore, the section “VVGng LS cable technical characteristics” in general characteristics is practically no different from the section of the same name in the article VVG brand cable. Acquainted with general characteristics VVGng(..)-LS is possible.

Application of VVGng(..)-LS cable

VVGng - LS cables related to fire hazard classes P1.8.2.1.2 and

P1.8.2.2.2 can be used for group installation in residential and public buildings, internal and external cable structures at industrial enterprises. It is allowed to use the cable at nuclear facilities.

Other cable options

- - round copper wire with PVC insulation of the outer and inner layers, has low gas and smoke emission during combustion in single and group installations;

- VVG-P - same as VVG, but flat design;

- - round copper wire with PVC insulation of the outer and inner layers, has low gas and smoke emission during combustion when laid alone;

- VVGng-P - same as VVGng, but flat design;

- VVGng-ls - round copper wire with PVC insulation of the outer and inner layers, has low gas and smoke emission during combustion in single and group installations;

- VVGng-Pls - same as VVG-ls, but flat design;

- VVGng-frls - round copper wire with fire-resistant PVC insulation of the outer and inner layers, has low gas and smoke emission during combustion in single and group installations;

- VVGng-Pfrls - same as VVGng-frls, but flat design.

Which does not spread combustion. In short, the VVGng decoding indicates this property with the last letters “ng”. This wire is usually used in power distribution or transmission. Due to this feature cable VVGng 3x1.5 , excellent for laying in bundles. Its almost complete versatility makes it possible to use it in different climatic conditions - from frosty northern to hot tropical climates. This cable is most often used where there is a high risk of fire - enterprises where they work with explosive or flammable components.

VVGng (a) transcript

According to the markings, we can understand what kind of cable it is. “VVG” stands for “vinyl-vinyl-naked,” thereby indicating that the cable has 2 layers of polyvinyl chloride in its structure, without any armor. What “NG” means was said at the beginning of the article. “A”, which is usually indicated in brackets, means the GOST type of flame retardation.

Even when laying cables in bundles, in the event of a fire, the combustion will not spread to other wires. Ordinary VVGs cannot boast of this property, except during solo installation. One small clarification: do not confuse the letter “a”, which is placed in front of the abbreviation - this means that the wire is aluminum. In our case, copper. As you can see, there is nothing difficult in remembering the decoding of the VVGng cable.

Laying methods

Open gasket. Based on the technical characteristics, the cable can be laid over structures, as well as surfaces that are not flammable. This could be concrete, brick, plastered surface, etc. It is also possible to lay it over suspended structures, such as a cable, but it is necessary to prevent stretching or sagging of the wire.

Gasket with protection. If there is a significant threat of mechanical damage to the wire, then it is necessary to provide a protective case, for example:

- pipe;

- cable channel;

- corrugated sleeve;

- metal hose, etc.

Hidden. Laying is carried out under the plaster, in voids or in specially made grooves. In this case, mechanical damage is unlikely, but the exceptions include the voids of wooden houses. In such cases, installation must be carried out in non-flammable pipe-type cases.

In the ground. The rules do not include laying the cable without special protection, because the wire does not have armor. Installation of the wire in such cases is carried out in sealed cases (boxes) along overpasses and cable structures.

Decoding of VVG power cable

Options for laying the VVG power cable can be different and depend on its characteristics. It can be pulled on power line supports, underground, on trays, in cable ducts inside buildings. It withstands humidity environment up to 98%.

The existing marking of any type of cable quite accurately indicates its main technical characteristics. In this case, we will consider a modification of the VVG power cable.

Letter marking of VVG cable;

— VVG marking means simple PVC insulation without any protective properties;

— VVG ng — insulation with self-extinguishing protection in case of fire;

— VVG ng-ls also has the property of self-extinguishing without the release of gas and smoke. This power cable brand VVG ng-ls is used where there is an increased fire hazard;

— VVG ng-fr-ls, in addition to the fact that it contains all the insulation properties of the VVG ng-ls power cable, it is also fire-resistant with a slight emission of gas and smoke.

Letter code for VVG power cable

By the marking and designation of each letter, you can easily determine the main characteristics of the power cable.

- Type of cable core material;

- A - aluminum;

- the absence of a letter indicates copper.

- Type of core insulation material;

- P - denotes a polymer;

— Pv — polyethylene insulation;

— B — insulation is made of polyvinyl chloride.

- Cable protection material;

— G — means that the cable is not armored, bare;

- B - this is how armored cable protection is marked.

- Material of external cable insulation (sheath);

— B — polyvinyl chloride insulation;

— Shv — the protective hose is indicated;

— Шп — polyethylene protective hose;

- P - polymer insulation.

- Marking of fire safety characteristics;

- in the absence of insulation combustion markings, it has the property of self-extinguishing combustion in the case of a single cable;

- ng - insulation with self-extinguishing property in a group of males;

— ng-hf — insulation with flame attenuation and minimal gas and smoke emission in a group of cables;

- ng-fr-ls - insulation burning does not spread in a group of cables, there is a slight emission of smoke and gas;

- ng-fr-hf - there is also no fire of insulation in a group of cables, no smoke, no gas emitted.

![]()

Thanks to the markings, you can easily decipher the VVG designation of the power cable. B - the material of the insulation cores is polyvinyl chloride, the next letter B indicates the sheath material of the entire cable - polyvinyl chloride, and the letter G means the absence of a protective layer (armor) of the cable cores, that is, the cable is bare. Let's summarize - IN inil - IN inil - G oly.

Further, the absence of the letter A indicates that the cable cores are made of copper. Also, the VVG cable has two fire safety groups - this is the designation ng-hf, when the insulation ignites, no gas is released, and the letter marking ng-ls shows that when the insulation ignites, a slight release of gas and smoke occurs. To these two designations the marking fr is added - this is increased fire resistance.

Variation of design according to the number of cores of the VVG power cable

In addition to the letter markings mentioned above, sometimes the letter P is added at the end of the designation, indicating that the cable is flat. The numbers 3 X 25 mm² or others are also added to the marking; they show that the VVG power cable has three cores with a cross-section of 25 mm² each. Before laying, the cross-section of the cable cores is calculated. The warranty period for VVG cable is usually 5 years, although its durability can exceed 30 years.

Cable VVG(a), also known as power wire VVG(a), also known as cable VVGng a, is a flame retardant wire that is used for the transmission and distribution of electricity, which occurs in stationary installations that have an electric current frequency of 50 Hz and a rated voltage of up to 660 or 1000 V. is extremely widely used - it is used in any climatic conditions, at high altitudes, in water - in fact anywhere, unless, of course, it is damaged. This subtype is especially often used in places where there is an increased risk of a fire - for example, in enterprises working with flammable or explosive components.

Decoding of VVG(a) cable

The marking allows us to understand in more detail what this cable is. Here is its decoding: “VVG” means “vinyl-vinyl-naked,” which refers to the presence of two layers of polyvinyl chloride, as well as the absence of a specialized protective layer. Well, “ng”, if used in marking, means that the cable, in the event of a fire hazard, will not spread combustion. The letter “a”, very often placed in brackets, means the category of non-propagation of combustion according to. In particular, this means that even when laid in bundles, these cables do not propagate combustion, while traditional VVGs can “boast” of this only when laid individually. This letter should not be confused with the “a” that is placed before the abbreviation and means that the cable is not copper. In this case it is definitely copper. Often ls, frls, frlsltx, frhf are added to the marking, but in essence this is one cable.

Technical characteristics of VVGng (a)

U VVGng A a number of parameters can vary. For example, this may be the form factor of the cores (which can be round, triangular or flat), their number (from 1 to, as a rule, 5), their sections (from 1.5 mm 2 to 50 mm 2, and sometimes even more), nominal diameter (directly dependent on cross-sections), weight (from several tens of kilograms to several tons per kilometer). The permissible current can vary from 21A to several hundred, depending on both the type of cable and its location. As you can see, there are a great many variations of this product, so before you buy a cable, you need to study in detail the description of its specific brand; it is this description that will save you time and nerves in the future. The price, again, varies depending on the complexity and size of the cable. But in comparison with other types of VVG, the cost remains at approximately the same level. But any cost is very justified, because the cable will serve you under proper operation conditions for more than thirty years, five of which, as a rule, will be under warranty.

U VVGng A a number of parameters can vary. For example, this may be the form factor of the cores (which can be round, triangular or flat), their number (from 1 to, as a rule, 5), their sections (from 1.5 mm 2 to 50 mm 2, and sometimes even more), nominal diameter (directly dependent on cross-sections), weight (from several tens of kilograms to several tons per kilometer). The permissible current can vary from 21A to several hundred, depending on both the type of cable and its location. As you can see, there are a great many variations of this product, so before you buy a cable, you need to study in detail the description of its specific brand; it is this description that will save you time and nerves in the future. The price, again, varies depending on the complexity and size of the cable. But in comparison with other types of VVG, the cost remains at approximately the same level. But any cost is very justified, because the cable will serve you under proper operation conditions for more than thirty years, five of which, as a rule, will be under warranty.