In our metric world, it is sometimes difficult to navigate other systems of measurement. We sometimes wonder how the Americans or the British can use outdated measures of length, mass, area, etc. And they, in turn, do not understand us - living by the laws unified system measurements. However, as in any rule, there are certain exceptions that are clear to everyone - and the inhabitants of America, and Foggy Albion, and Europe, and Russia. This article is devoted to an overview of pipe and metric threads, the variety of which is encountered quite often in everyday life.

Metric threads and their applications

Threaded connections are very common in construction, engineering, mechanical engineering, aerospace and everyday life. What is a screw and a nut even children in kindergarten, since classes with the designer cannot do without these details. Despite the fact that the first screw was invented by Archimedes, and our ancient ancestors widely used screw gears in presses to extract oil from olive pits and sunflower seeds, as well as to raise water for irrigating fields, the idea of creating a real screw connection has found its realization. only in the 15th century, when one of the Swiss watchmakers for the first time managed to turn the first screw and nut with the help of the simplest devices.

At the same time, humanity did not come to a reasonable idea that the carving should be the same in all countries of the world. So, widespread and familiar to everyone who has even a little experience with technology, metric thread appeared and was described in the standards only after the introduction of a unified measurement system based on the standards of the meter, kilogram and second. So the appearance and wide distribution of metric thread dates back to the end of the 19th century. Until that time, inch threads dominated the world.

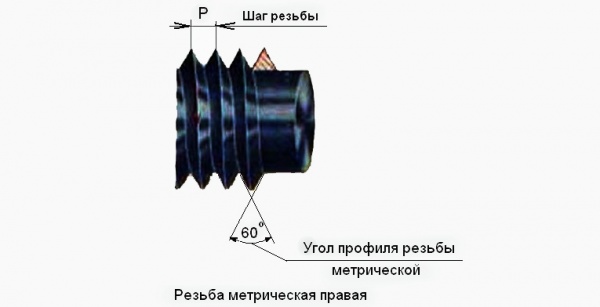

The main difference between a metric thread and an inch thread is that all its parameters are tied to a millimeter, and an equilateral triangle is taken as the basis for the profile of the thread itself, since all its angular dimensions are the same and equal to 60 degrees. In the standardization of metric threaded connections, it is important that the nut and bolt match not only the angular dimensions of the thread, but also its diameter and pitch. Many, especially those who have cars, have encountered an incomprehensible phenomenon when the screw and nut have the same diameter, but it is impossible to screw the screw into the nut. This indicates that a thread with a smaller pitch is used in this place, and in order for the screw to be screwed in without problems, its thread pitch must also be reduced.

The standards describing metric threads indicate that they should be designated with the letter M, followed by the diameter of the thread and its pitch. The range of metric thread diameters ranges from one to six hundred millimeters. The spread of the thread pitch is from 0.075 to 3.5 mm. Threads with a small pitch are used for measuring tools, threads with a medium pitch are used for parts and assemblies loaded and operating under vibration conditions, and threads with a large pitch are used for fastening heavy load-bearing structures.

When creating standards for metric threads, various tolerances were taken into account, which set the degree of roundness of the outer edge of the thread and deviations from the profile so that the screw and nut can be freely tightened to the stop by hand.

Although metric threads have not found wide application in sealed joints, however, this possibility is included in the standards. Thus, a thread with the designation MK is used for self-sealing connections due to the taper of the outer and internal thread. Moreover, for a tight connection, it is not necessary that the screw and nut be with a conical thread. It is sufficient that this thread be cut on the screw.

Cylindrical metric thread is quite rare. Its designation is MJ. The main difference is in the screw, which has an increased thread root radius, which gives the threaded connection based on a cylindrical metric thread higher heat-resistant and fatigue qualities. This thread is used in the aerospace industry. However, a regular metric screw can be screwed into a nut with such a thread.

Despite the total predominance of right-handed threads in all devices and mechanisms, it is still necessary to use left-handed threads to implement certain functions. Metric left hand threads do not differ in any way from right hand threads, except for the direction of rotation, which is opposite to right hand screws. If a regular screw is turned clockwise, then the left one is unscrewed in the same direction.

You can also sometimes meet with multi-start metric threads. It differs in that not one spiral, but two or even three, is simultaneously cut on the bolt and nut. Multi-start threads are often used in high-precision equipment, for example, in photographic equipment, in order to uniquely position the position of parts during mutual rotation. Such a thread can be distinguished from the usual one by two or three beginnings of the turns at the end.

Despite the very widespread use of metric threads, in many developed countries of the world, the so-called inch threads traditionally remain in greater use. And pipe threads are universally measured in inches. And, despite the strong differences between these types of threads, plumbers around the world do not need to explain the differences between a half-inch pipe and a three-quarter one.

Inch threads and their application

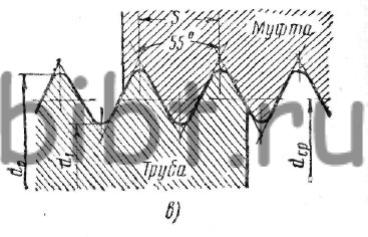

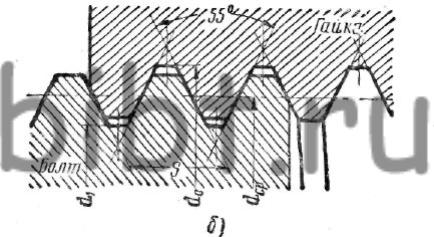

The difference between inch and metric threads is that the angle at the top of the thread is 55 degrees, the thread pitch is calculated as the ratio of the number of threads per inch of thread length. An inch is understood as a distance equal to 2.54 cm. Which originally corresponded to the length of the first phalanx of the thumb of a person, which is the same for almost all people.

Since the angle at the top is different than in metric threads, it is not possible to combine metric and inch threads. In countries with the metric system, only inch pipe threads are used, which are denoted by the letter G. The letter is followed by a fractional or integer denomination, which indicates not the size of the thread, but the conditional clearance of the pipe in inches or fractions of an inch. A feature of the pipe thread is precisely the fact that it takes into account the thickness of the pipe walls, which can be thicker or thinner depending on the material of manufacture and the working pressure for which the pipes are designed. Therefore, the inch standard of pipe threads is understandable and accepted throughout the world as an exception to the metric rules.

In addition to simple cylindrical pipe threads, there is also a conical pipe thread. It has the same characteristics as a conventional pipe, with the exception of the taper, which allows you to create more tight connections. Designated with the letter R for external thread and Rc for internal. The left-hand thread is additionally marked with the letters LH, followed by a numerical value in whole and fractional fractions of an inch.

For use in connections other than plumbing, in the USA and Canada, inch threads with an angle at the top of 60 degrees are used. There is a fairly wide assortment of these threads, which differ in the range of thread pitch and other characteristics. It is worth noting that some threads from the inch series coincide with the metric ones, which in some cases can be beneficial. For example, in photographic equipment, the diameter of the connecting thread, through which the camera is attached to a tripod, is the same all over the world, regardless of the country of manufacture, since the characteristics of this thread are the same for both metric and inch thread.

However, do not confuse the English inch industrial thread, which was approved back in 1841, and Joseph Whitworth himself was involved in its development. This thread practically repeats the pipe thread, as it has an angle at the top of 55 degrees. Screws and nuts with this thread will not mate with inch fasteners from America and Canada.

In mechanical engineering, three thread systems are adopted: metric, inch and pipe.

Metric thread(Fig. 145, a) has a triangular profile with a vertex of 60 °.

Rice. 145. Thread systems: a - metric, b - inch, c - pipe

There are six types of metric threads: main and small -1; 2; 3; 4th and 5th. Fine threads differ in the pitch for a given diameter, expressed in millimeters. Metric threads are indicated by the letter M and numbers characterizing the dimensions of the outer diameter and pitch. For example, M42X4.5 denotes a metric base with an outer diameter of 42 mm and a pitch of 4.5 mm.

Fine thread, in addition, in the designation has a number indicating the thread number, for example 2M20X1.75 - the second metric fine, outer diameter 20 mm, pitch 1.75 mm.

Inch thread(Fig. 145, b) has an angle of 55 ° at the top. Inch threads are cut in the manufacture of spare parts for machines with inch cuts and should not be cut on new products. An inch thread is characterized by the number of threads per inch (1") of length. The outer diameter of an inch thread is measured in inches.

Pipe thread(Fig. 145, c) is measured in the same way as inch, in inches and is characterized by the number of threads per 1 ". The thread profile has an angle of 55 °. For pipe threads, the diameter of the pipe hole is conventionally taken as diameter, on outer surface which the thread is cut.

The tops of the protrusions of the screw and the nut with pipe threads are made with flat or rounded cuts.

The flat cut profile is easier to manufacture and is used for threads of conventional pipe connections. The pipe thread is indicated: 1/4 "PIPE; 1/2" PIPE. etc. (Table 25).

Table 25 Designation of threads in the drawings

| thread type | Conventions | Symbol elements | Example of bolt and nut thread designation |

Metric basic |

M | Thread outer diameter (mm) or outer diameter and pitch (mm) | M64 or M64X6 or 64x6 |

Metric fine |

1M | 1M 64X4 or 64X4 | |

| 2M | 2M 64X3 or 64X3 | ||

| 3m | 3M 64X2 or 64X2 | ||

| 4M | 4M 64X1.5 or 64X1.5 | ||

| 5M | 5M 64X1 or 64X1 | ||

Trapezoidal |

LADDER | Outer diameter and thread pitch (mm) | LADDER. 22x5 |

| UP | UE 70X10 | ||

Inch with a profile angle of 55° |

Nominal thread diameter in inches | 1" | |

Pipe cylindrical |

PIPE. PR* PIPE. KR ** | Symbol threads in inches | 3/4" PIPE. PR 3/4" PIPE. KR |

Pipe conical |

PIPE. CONIC. | 3 / 4 " TUBE TAPERED |

* Profile with flat cut tops (straight). ** Profile rounded.

Threads are right and left; according to the number of passes - one-, two-, three-way and multi-way.

In order to determine the number of thread starts, it is enough to look at the end of the screw or nut and count how many ends of the turns are on it.

As a rule, all fasteners (bolts, screws, screws, etc.) have a single thread.

Which are in inches. Many buyers may not pay attention to this, and, therefore, there is a possibility of purchasing a pipe with a size that does not correspond to the required one. The reason for this lies in the fact that the inch on the surface of the pipe), as the name implies, is measured in inches. In this case, one inch is equal to 25.4 millimeters. This value differs from the accepted millimeter standards, which can greatly complicate the selection of the required part.

An inch cylindrical thread provides for the display of pipe dimensions in inches, while it is indicated in fractions of this unit of measurement (due to its small size).

Due to the discrepancy between the millimeter and inch values, in practice there is a significant difference between the thread sizes on the pipe. This is because Western standards say: inch thread means internal. In this case, the differences between the metric inch and the so-called pipe should be taken into account.

For example, the pipe indicates that the inch thread has a size of ½. Thus, you get a pipe with an outer diameter of 20.95 mm, instead of the expected 12.7 mm. Therefore, the pipe inch is equal to 33.249 mm and consists of the size of the direct passage and twice the wall thickness.

From this example it can be seen that the use of this indicator is more acceptable, since such a system best characterizes the size that an inch thread has.

Now that the designations have become clear, we can proceed to the classification and purpose of this parameter.

Cylindrical inch thread according to the purpose and nature of the work performed is divided into:

- Mounting thread. This type traditionally includes metric and inch threads, which have a triangular profile. Metric is used in the design of new machines and units, while the second is necessary for the production of various spare parts.

- Special threads include many different non-standard sizes.

Often produced with a profile having an angle of 60 °. All quantities, whether it be thread pitch or outer diameter, are indicated in millimeters.

By the size of the pitch, one main and 5 types of auxiliary threads are distinguished (it is also called fine). It should be noted that such a thread is considered more durable than a large one (with absolutely equal outer diameters). The undoubted advantage of a fine thread can also be called a small helix angle and, as a result, increased resistance to twisting.

Threads of this type are used in the most loaded hollow parts, as well as in elements that are subject to strong shocks and shocks. The adjusting nuts also have a similar thread as it allows for finer adjustment.

In addition, inch threads can be made with a rotation angle of 55°. In this case, the diameter is still specified in inches, but the thread pitch is determined by the number of threads per inch. A similar type is used in various parts for mechanical fixation to each other.

In Western technical literature, you will find all measurements in inch metrics. This state of affairs has historical roots. Great Britain has always been ahead in terms of the level of technical development, therefore, in all the colonies that it then owned (and there were many), it was this system of measurements that was applied. In principle, technicians are free to convert inches to sentiment and vice versa. So to this day in these countries, as a standard, all measurements are made in inches. Next, we will talk about the main features and characteristics of inch threads and how it differs from metric.

Inch thread. Options

If we talk about the usual measurement, then even in the mind it will not be difficult to transfer one value to another and vice versa. But as far as threading is concerned, you need to know simple, but important nuances. The fact is that the metric and inch metrics for measuring lengths are great coincidences. The difference is the number of turns per threaded pitch. In addition, this thread is characterized by a different angle of inclination at its top, which is equal to 55 °, if we refer to the style of Whitworth. This is considered the norm in England, or, as they say, the "British corner". If we take as a basis the UNC and UNF standard, which is considered the standard in America, then the angle here is 60 °.

Metric standard and inch thread. The most fundamental differences

Types of inch thread:

- outdoor;

- conical;

- Cylindrical;

- Internal.

1 inch = 25.4 mm. This is the main difference. In documents, this has a specific designation - 1´ (with a stroke).

If we talk about American standards, then they have a division into large-pitch threads, which they designate as UNC and with small ones - UNF. Also, for canonical inch threads, the designation NPT is established, and for pipe - NPSM.

What is carving and where is it used

The types of threads used in production, construction and design, depending on the part, are divided into internal, external and conical.

- External is used for bolts, screws, pins and studs.

- Internal is used in the manufacture of plugs or nuts. It is cut into holes when you need to organize a connection in a certain place.

- To create a tight connection, as well as locking without additional parts, a conical inch thread is made.

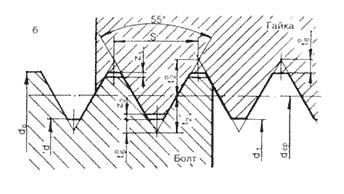

Their designation follows the standard. d (D) is the outer diameter of the bolt or the inner diameter of the nut (d is the diameter of the bolt before threading). The internal thread diameter is designated d1 (D1). There is also a designation for the average diameter d2 (D2). This size depends on the nominal pitch, denoted by the letter P.

The letter α is used to designate the profile angle of the thread. A value of α = 55° will mean that the equilateral triangle apex angle of the thread tooth is 55°, and corresponds to the British Standard BSW inch thread. The inch UTS thread, which is widely used in Canada and the USA, has α = 60°.

Where is inch thread used

α = 55° - inch thread used in industry for fixing mechanical components and parts using threaded connections. It is especially common in the process of repairing imported equipment and machine tools, as well as used cars. Metal products with inch threads are also produced in our country. During operation, sometimes there is a need to convert metric threads to inch threads and vice versa. This can be easily done quickly and conveniently with the help of a special reference book.

Threads according to the system of measures are divided into metric and inch. Metric and inch threads are used in threaded connections and screw gears. Threaded connections are detachable connections made using threaded fasteners - bolts, screws, nuts, studs or threads directly applied to the parts to be joined.

Metric thread (fig. 1)

It has the form of an equilateral triangle in the profile with an angle at the top equal to 60 °. The tops of the protrusions of the mating screw and nut are cut off. The metric thread is characterized by the screw diameter in millimeters and the thread pitch in millimeters. Metric threads are made with coarse and fine pitch. The thread with a large step is taken as the main one. Fine threads are used for adjustment, for screwing thin-walled, as well as dynamically loaded parts. Large-pitch metric threads are denoted by the letter M and a number expressing the nominal diameter in millimeters, for example, M20. For fine metric threads, the pitch is additionally indicated, for example, M20x1.5.

Rice. 1 Metric thread

Inch thread (fig. 2)

An inch thread (Fig. 2) has the same appearance in profile as a metric thread, but it has a 55 ° corner angle (Whitworth thread - British standard BSW (Ww) and BSF), a corner angle of 60 ° (American standard UNC and UNF). The outside diameter of the thread is measured in inches (1" = 25.4mm) - dashes (") indicate an inch. This thread is characterized by the number of threads per inch. Inch American threads are made with coarse (UNC) and fine (UNF) pitch.

Rice. 2 inch thread

Fastener Size Chart for U.S. Inch Coarse Pitch UNC Machine Thread (60 Degree Profile Angle)

| Size in inches | Size in mm | Thread pitch / inch |

| UNC No. 1 | 1.854 | 64 |

| UNC No. 2 | 2.184 | 56 |

| UNC No. 3 | 2.515 | 48 |

| UNC No. 4 | 2.845 | 40 |

| UNC No. 5 | 3.175 | 40 |

| UNC No. 6 | 3.505 | 32 |

| UNC No. 8 | 4.166 | 32 |

| UNC No. 10 | 4.826 | 24 |

| UNC No. 12 | 5.486 | 24 |

| UNC 1/4 | 6.35 | 20 |

| UNC 5/16 | 7.938 | 18 |

| UNC 3/8 | 9.525 | 16 |

| UNC 7/16 | 11.11 | 14 |

| UNC 1/2 | 12.7 | 13 |

| UNC 9/16 | 14.29 | 12 |

| UNC 5/8 | 15.88 | 11 |

| UNC 3/4 | 19.05 | 10 |

| UNC 7/8 | 22.23 | 9 |

| UNC 1" | 25.4 | 8 |

| UNC 1 1/8 | 28.58 | 7 |

| UNC 1 1/4 | 31.75 | 7 |

| UNC 1 1/2 | 34.93 | 6 |

| UNC 1 3/8 | 38.1 | 6 |

| UNC 1 3/4 | 44.45 | 5 |

| UNC 2" | 50.8 | 4 1/2 |

Thread

The thread can be internal and external.

- On bolts, studs, screws, pins and on various other cylindrical parts, an external thread is cut;

- In fittings, nuts, flanges, plugs, machine parts and metal structures, internal threads are cut.

Rice. 3 Thread elements

The main elements of the threads are shown in fig. 3 These include the following elements:

- thread pitch- the distance between the tops or bases of two adjacent turns;

- thread depth- distance from the top of the thread to its base;

- thread profile angle- the angle enclosed between the sides of the profile in the plane of the axis;

- outside diameter- the largest diameter of the thread of the bolt, measured along the top of the thread perpendicular to the axis of the thread;

- inner diameter- a distance equal to the diameter of the cylinder at which the thread is screwed.

More about inch fasteners: