The word "valve" came into Russian from German language not so long ago ─ in the 18th century. In it, Klappe means lid. And indeed, like a lid, a valve is capable of opening and closing a passage for something.

Valves surround a person everywhere. They are part of him. All living creatures with a heart beating in their chest have heart valves that regulate blood flow.

The flaps cover the pockets of jackets, coats, and bags. Valves are used in printing (book cover valve). They are no strangers to art: with the help of the valves of wind instruments, the air exhaled from the lungs is transformed into the sounds of music.

Valves are widely used in technology:engine valve, pump valve, compressor valve. Every car enthusiast knows what it isadjustment of valvesorvalve replacement. And finally

Valve ─ one of the types of pipeline fittings

It will never be possible to establish for certain who was the first to use the valve in this capacity, but prototypes of modern valves were used many centuries ago in the aqueducts of Ancient Rome.

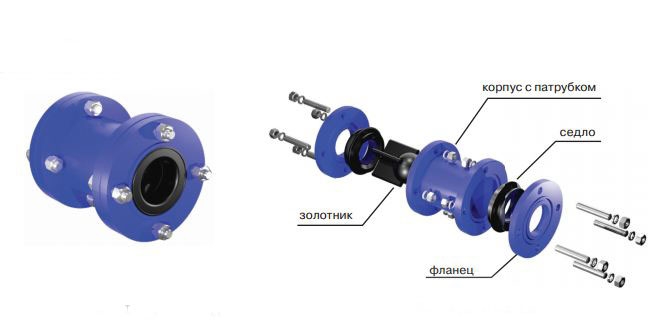

In pipeline fittings, a valve is one of its types, along with gate valve, tap and butterfly valve. A distinctive feature of a valve is a locking or regulating element that moves parallel to the axis of the flow of the working medium.

Exists big number types of valves. As the main component, they are included in the design of most regulators, air vents and a considerable part of condensate traps.

Main properties of valves:

- low construction height;

- fast response;

- high tightness;

- presence of back pressure of the working environment;

- big hydraulic resistance;

- significant force on the shutter drive;

- large construction length.

The first three positions in this list refer to the absolute advantages of valves. The last three are not his strongest points.

Valves are at the same time “relatives” and in some ways antipodes of another type of fittings - gate valves. For both of them, the movement of the shut-off or control element is linear, in contrast to taps and butterfly valves, in which it is rotational. And at the same time, many of the properties listed in the previous paragraph of valves and gate valves are multidirectional. The latter have a large construction height, short construction length, low hydraulic resistance, and slow response. Shut-off valves open and close the passage faster than gate valves, which is useful for frequent switching. But, unlike valves, when passing shut-off valve the flow has to change direction.

Valve and types of pipeline fittings

Virtually any type of fittings has found its structural embodiment in valves. Valves are present in all types of fittings according to their purpose and area of application: general industrial, sanitary, pressure reducing, control, energy and others. A safety valve made in the form of a valve is called a safety valve, a non-return valve is a check valve, a control valve is called a control valve, etc.

There are shut-off, mixing, distribution, separating, shut-off valves. Valves are an integral part of the design of a significant part of technical devices ─ representatives of phase separating valves.

Serves to automatically protect equipment and pipelines from unacceptable excess pressure by releasing excess working fluid. Non-return valve ─ to automatically prevent the backflow of the working fluid. ─ to regulate its parameters by changing the flow rate or flow area.

Example check valve─ a foot valve installed at the end of the pipeline in front of the pump.

A type of control valve ─ breathing valve (other names ─ inlet or outlet valve), designed for sealing containers containing gas, air or steam. Also an integral part of the control valves is a bypass valve, which serves to periodically reduce the pressure in the pipeline and equipment “to itself” if it exceeds the set value.

Valve body

Depending on the method of forming the body, valves can be forged, cast, welded, stamped or combined: litho-welded (in which body parts made by casting are joined by welding), stamp-welded (body parts produced by stamping, forging or rolling are joined by welding), litho-stamp-welded.

According to the type of configuration of the connecting pipes, angle and straight valves are distinguished. For angle valves, the axes of the inlet and outlet pipes are located perpendicular or at least non-parallel to each other. For pass-throughs they are mutually parallel. When passing an angle valve, the flow makes one turn, so the pressure drop in it is less than in a straight-through (through) valve.

Valves can have not only two pipes - inlet and outlet, but also be multi-port. “Many-” ─ this is usually three ( three-way valve) or four (four-way valve) pipes.

Like other types of pipeline fittings, valves are available in full bore and partial bore types. In the first case, the diameter of the seat is at least 9/10 of the diameter of the inlet pipe opening; in the second case, the cross-sectional area of the flow path is less than this value.

Valve designs

The general principle of the valve design is the same ─ movement of the moving parts of the valve relative to the stationary ones leads to a change in the flow area, and, therefore, a change in throughput. But the valve shutter design varies.

For example, the movable valve element ─ spool ─ can be needle-shaped (in the form of a narrow cone), piston (cylindrical), spherical, or disc-shaped.

The needle valve offers high performance and provides efficient flow control.

In a piston safety valve, the piston is a sensitive element that senses the pressure of the working medium.

In a control cage valve, the valve is a fixed part, called a cage due to the large number of profiled holes that serve to pass the working fluid. A plunger moving inside the cage, changing the area of their open sections, regulates the throughput of the valve.

Based on the number of seats, a distinction is made between single-seat and double-seat valves, when two seats are on the same axis.

If the valve's flow area is formed by two or more valves arranged in series, it is called a multi-stage valve.

According to the type of seal that ensures the required tightness of valve connections relative to the external environment, we can note stuffing box and bellows valves. In a bellows safety valve, the bellows not only serves to seal the stem, but also serves as a sensitive or force element. Bellows seals are used in many valves: shut-off, control, safety.

According to their mode of action, valves can be normally closed (NC valve) and normally open (NO valve). NC valves, in the absence or cessation of the energy supply that creates the force to move the locking (regulating) element, automatically ensure the “closed” position, and NO valves, under the same conditions, provide the “open” position.

Connecting the valve to the pipeline

The efficiency and duration of their operation in the composition largely depends on the quality of valve installation. pipeline system. When connecting valves to a pipeline, all known technologies are used.

Coupling connections, when the connecting pipes have internal threads, are especially widely used for valves whose body is made of non-ferrous metal alloys.

To connect small-sized valves, union and pin connections are used ─ connecting pipes with external thread, and in the pin type ─ with an external thread and a collar.

Flange connections provide convenient installation and dismantling, but require more careful control of the tightening of the fastening bolts, loosening of which threatens loss of tightness. To enhance the tightness, sealing gaskets are installed between the flange surfaces. Weak side flange connections─ possibility of deformation of flanges. Cast iron flanges resist it better than other materials.

Welded joints are permanent, so their dismantling is difficult. But they are widely used for steel valves in pipeline systems transporting explosive, radioactive, toxic liquids and gases. Welded joints made “once and for all” do not require maintenance or tightening, unlike, for example, flanged joints. This is true for those stretching for hundreds and thousands of kilometers. main pipelines, fulfill Maintenance which are not so simple. Welded joints do not lead to an increase in the weight of pipeline fittings, and, therefore, of pipelines as a whole. The main thing is that the welding site does not become a weak point of the pipeline system in terms of mechanical properties.

Actuators for valve control

To control valves ─ move a locking or regulating element ─ a variety of methods are used: manual, electric, electromagnetic, hydraulic, pneumatic or combinations thereof.

Examples of a combined drive are a pneumatic-hydraulic drive using compressed gas energy and hydraulic energy, and an electro-hydraulic drive.

The transmission of translational force from the drive to the locking or control element is carried out through a rod (spindle).

Electric actuators are widely used to control control valves in heating, ventilation and air conditioning systems. A modern electric drive is a complex technical device, including a control system, an electric motor and a gearbox.

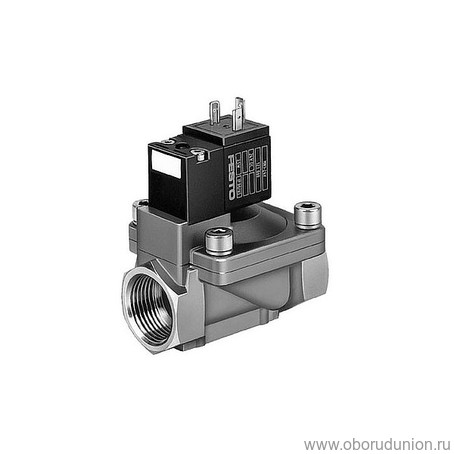

If in an electric drive electrical energy is used “directly,” then in an electromagnetic drive its transformation into mechanical energy occurs as a result of the interaction of the electromagnetic field and a core made of ferromagnetic material.

A solenoid valve equipped with a built-in or remote solenoid drive is a common design.

Solenoid valves can be powered by alternating current centralized electrical networks or from direct current of autonomous sources ─ batteries or direct current generators.

Solenoid valves are widely used in instrumentation and control equipment; for controlling the processes of dosing, shutting down, mixing, dumping, and distributing flows of working media.

For many years, pneumatic actuators have been used to control valves, applicable to almost all valve sizes except the largest ones, where they are supported by a high-torque hydraulic actuator.

The use of actuators allows you to automate the operation of valves. Requirements for valve drives: guarantee of the required operating range (output torque), wear resistance, tightness, compliance with safety requirements, corrosion resistance.

Materials for making valves

The entire arsenal is used in the manufacture of valves modern technologies. Valve bodies can be made of ferrous and non-ferrous metals and their alloys, as well as non-metallic materials. Ferrous metals ─ cast iron (gray, malleable) and steel ─ carbon, low-alloy, high-alloy, including heat-resistant and stainless. Non-ferrous metals ─ alloys of copper, nickel, tantalum, titanium, niobium, aluminum (for example, aluminum unified air valve UVK). Non-metallic materials ─ plastics, ceramics (porcelain), etc.

Valve seats operating at small pressure drops are made of cast iron or aluminum alloys; for higher loads they are made of steel.

It is interesting that in the description of the materials used for the manufacture of valves, more than a century ago, both the well-known cast iron, copper, bronze and rubber are mentioned, as well as the less well-known lead, leather, glass and wood.

The emergence of new and more complete use of the capabilities of “old” materials is one of the important reserves for increasing the potential of modern valves.

IN different periods history of the development of valve engineering came to the forefront different types fittings. One of the leading Russian specialists, expert of the NPAA (Scientific and Industrial Association of Valve Manufacturers), Ph.D.HE. Shpakov considers the decades following the invention of the steam engine to be the peak of valve leadership. Then his burden shifted to the valves. Sales figures various types fittings rather confirm than refute this opinion.

But where other types of fittings find it difficult to compete with valves is variety. To describe it for valves, terms are required several times more than, for example, for gate valves. What convincing evidenceAlphabetical index of terms in Russian « GOST 24856-2014. Pipeline fittings. Terms and Definitions".

Reinforcement valve ACL E107BB10 with diaphragm reinforcement, body - brass, with connecting thread G1/4, type 2/2, normally closed, electrically controlled (coil must be ordered separately: when ordering, indicate voltage and type of current - alternating or direct) designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils, etc.) under pressure. The action of the valve is based on the opening or closing of the passage hole in the valve pair using the direct action of a magnetic field on the plunger created by the electric field in the electric coil.

Parameters of reinforcement valve ACL E107BB10:

Version: threaded installation G1/4 (pipe, cylindrical)

Nominal diameter: 10 mm

Minimum pressure drop: 0.15 bar

Maximum pressure drop: 15 bar

Air consumption: 1.5 m3/hour

Body material: brass

Price: 3,033.45 rub.

COIL (TYPE 2) ACL 20B ~24V, 50/60Hz FOR VALVE VALVE

Coil (type 2) ACL 20B ~24V, 50/60Hz

Parameters of the coil (solenoid) ACL 20B:

Version: type 2

Voltage: ~24V, 50/60Hz

Bore hole diameter: 13 mm

Connector standard: DIN 43650/A

Weight: 120 g

Price: RUB 1,101.03

COIL (TYPE 3) ACL 30B ~24V, 50/60Hz FOR VALVE VALVE

Coil (type 3) ACL 30B ~24V, 50/60Hz for a reinforcing valve (valve with a reinforcing tube) is used to control the valve. Control occurs by applying or turning off voltage to the coil contacts.

Parameters of the coil (solenoid) ACL 30B:

Version: type 3

Voltage: ~24V, 50/60Hz

Material: Nylon + fiberglass

Connector standard: DIN 43650/A

Connector code: 305.11.00 (supplied separately)

Weight: 120 g

Price: 823.90 rub.

ARMATED VALVE ACL E105AB12 (2/2, NC, G1/8)

Reinforcement valve ACL E105AB12 direct action, body - brass, with connecting thread G1/8, type 2/2, normally closed, electrically controlled (the coil must be ordered separately: when ordering, indicate the voltage and type of current - alternating or direct) designed to control the flow of various gases and liquids ( air, water, steam, alcohols, oils, etc.) under pressure. The action of the valve is based on the opening or closing of the passage hole in the valve pair using the direct action of a magnetic field on the plunger created by the electric field in the electric coil.

Parameters of the valve ACL E105AB12:

Nominal bore: 1.2 mm

Function: 2/2, normally closed

Seal: NBR (oil- and petrol-resistant rubber)

Control type: electromagnetic

Minimum pressure drop: 0 bar

Maximum pressure drop: 25 bar

Air consumption: 0.04 m3/hour

Temperature environment: -10...+55 °C

Installation position: preferably with the coil facing up

Body material: brass

Ordering note: Reel must be ordered separately

Price: RUB 1,498.00

COIL (TYPE 4) ACL 401 =24V FOR VALVE VALVE

Coil (type 4) ACL 401 = 24V for a reinforcing valve (valve with a reinforcing tube) is used to control the valve. Control occurs by applying or turning off voltage to the coil contacts.

Parameters of the coil (solenoid) ACL 401:

Version: type 4

Voltage: =24V, power 5W

Material: Nylon + fiberglass

Bore hole diameter: 10 mm

Connector standard: DIN 43650/A

Connector code: 300.11.00 (supplied separately)

Weight: 100 g

Price: RUB 1,198.40

ARMATED VALVE ACL W106BV30///201 (2/2, NC, G1/4, =24V)

Reinforcement valve ACL W106BV30///201 direct action, body - brass, with connecting thread G1/4, type 2/2, normally closed, electrically controlled (=24V) designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils, etc.) under pressure.

Parameters of reinforcement valve ACL W106BV30///201:

Version: direct acting valve

Connection: threaded installation G1/4 (pipe, cylindrical)

Nominal diameter: 3 mm

Function: 2/2, normally closed

Seal: Viton = -10...+130 °C

Control type: electromagnetic (=24V)

Min. differential pressure: 0 bar

Max. pressure drop: 6 bar

Air consumption: 0.18 m3/hour

Ambient temperature: -10...+55 °C

Installation position: preferably with the coil facing up

Body material: brass

Price: 2,247.00 rub.

REINFORCEMENT VALVE ACL E111AB12///301 (2/2, NC, G1/8, =24V, STAINLESS STEEL)

Reinforcement valve ACL E111AB12///301 direct action, housing - stainless steel(case strength 50 bar), with connecting thread G1/8, type 2/2, normally closed, electrically controlled (=24 V DC) designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils and other) under pressure.

Parameters of the valve ACL E111AB12///301:

Version: direct acting valve

Connection: threaded installation G1/8 (pipe, cylindrical)

Nominal bore: 1.2 mm

Function: 2/2, normally closed

Seal: NBR = -10...+90 °C

Control type: electromagnetic (=24 V DC)

Min. differential pressure: 0 bar

Max. pressure drop: 25 bar

Air consumption: 0.04 m3/hour

Ambient temperature: -10...+55 °C

Installation position: preferably with the coil facing up

Case material: stainless steel

Price: 4,568.90 rub.

VALVE FESTO VZWM-L-M22C-G14-F4 (2/2, NC, G1/4)

Reinforcement valve Festo VZWM-L-M22C-G14-F4- this is a diaphragm valve with electromagnetic control (the coil must be ordered separately: when ordering, indicate the voltage and type of current - alternating or direct), with a connecting internal thread, type 2/2, normally closed, electrically controlled, is designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils, etc.) under pressure. The action of the valve is based on the opening or closing of the passage hole in the valve pair using the direct action of a magnetic field on the plunger created by the electric field in the electric coil.

Parameters of the Festo VZWM-L-M22C-G14-F4 reinforcement valve:

Version: seat valve with diaphragm seal

Stop valve connection: G1/4 internal (pipe, cylindrical)

Electrical connection: MD type solenoid coil (to be ordered separately)

Operating pressure for valve in liquid media: 0.5 ... 6 bar

Operating pressure for valve in gaseous media: 0.5 ... 10 bar

Reset type: air spring

Temperature of gaseous medium: -10 ... 60 °C

Liquid temperature: 5 ... 50 °C

Standard nominal flow: 1400 l/min

Valve weight without coil: 0.5 kg

Price: 4,508.98 rub.

ELECTROMAGNETIC COIL FESTO MD-2-24VDC-PA (24V, DC)

Electromagnetic coil Festo MD-2-24VDC-PA(or, in other words, solenoid) for direct current, without a plug socket, is used to control valves, for example, the Festo VZWM-L valve.

Coil parameters Festo MD-2-24VDC-PA:

Version: for valves, e.g. for Festo VZWM-L valves

Duty cycle: 100%

Ambient temperature: -20 ... 50 °C

Reel weight: 110g

Electrical connection: according to DIN EN 175301-803

Mounting type: with knurled nut

Price: 1,175.93 rub.

REINFORCEMENT VALVE FESTO VZWD-L-M22C-M-G18-20-V-1P4-15

Reinforcement valve Festo VZWD-L-M22C-M-G18-20-V-1P4-15- this is a poppet valve with a connecting internal thread, type 2/2, normally closed, electrically controlled, designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils, etc.) under pressure.

Parameters of the Festo VZWD-L-M22C-M-G18-20-V-1P4-15 reinforcement valve:

Version: Directly operated poppet valve

Stop valve connection: G1/8 internal (pipe, cylindrical)

Valve function: 2/2 N.C., monostable

Flow direction: irreversible

Working medium: compressed air, inert gases, water, neutral liquids

Coil characteristics: 24 V DC: 6.8 W

Operating pressure: 0 ... 15 bar

Reset type: mechanical spring

Max. medium viscosity: 22 mm2/s

Standard nominal flow: 140 l/min

Material information, body: brass

Valve weight: 0.3 kg

Price: RUB 3,655.12

PNEUMATIC VALVE FESTO MN1H-2-3/8-MS (2/2, NC, G3/8)

Pneumatic valve Festo MN1H-2-3/8-MS with auxiliary manual control, without solenoid coil and plug socket. The electromagnetic coil and plug socket must be ordered separately.

Parameters of the Festo MN1H-2-3/8-MS pneumatic valve:

Version: diaphragm valve

Stop valve connection: G3/8 internal (pipe, cylindrical)

Electrical connection: solenoid coil type MSN1 (to be ordered separately)

Valve function: 2/2 N.C., monostable

Flow direction: irreversible

Working medium: compressed air, filtration degree 200 microns

Operating pressure: 0.5 ... 10 bar

Reset type: air spring

Ambient temperature: -10 ... 60 °C

Standard nominal flow: 2900 l/min

Material information, body: brass

Air valve weight without coil: 0.45 kg

Price: 8,538.60 rub.

VALVE FESTO VZWP-L-M22C-G14-130-1P4-40 (G1/4, 24V)

Reinforcement valve Festo VZWP-L-M22C-G14-130-1P4-40- this is a pilot-controlled poppet valve, with a connecting internal thread, type 2/2, normally closed, electrically controlled, designed to control the flow of various gases and liquids (air, water, steam, alcohols, oils, etc.) under pressure.

Parameters of the Festo VZWP-L-M22C-G14-130-1P4-40 reinforcement valve:

Version: pilot operated poppet valve

Connection: G1/4 internal (pipe, cylindrical)

Electrical connection: via connector according to EN 175301-803, version A

Valve function: 2/2 N.C., monostable

Flow direction: irreversible

Working medium: compressed air, inert gases, water, neutral liquids

Coil characteristics: 24 V DC: 6.8 W

Operating pressure: 0.5 ... 40 bar

Permissible voltage fluctuations: +/- 10%

Max. medium viscosity: 22 mm2/s

Liquid temperature: -10 ... 80 °C

Standard nominal flow: 1600 l/min

Material information, body: brass, number CW617N

Valve weight: 0.60 kg

Price: RUR 12,133.80

PNEUMUMIC PULSE VALVE FESTO VZWE-E-M22C-M-G34-200-H (G3/4)

Pulse pneumatic valve Festo VZWE-E-M22C-M-G34-200-H represents N.Z. 2/2 valve with pilot control. Designed to generate pulses of compressed air for mechanical cleaning of dust filters. The valve is controlled by short electrical pulses supplied to an electromagnetic coil (coil and connector must be ordered separately). Powerful short pulses of compressed air generated by the valve pass through the filter against the standard flow direction of the filter unit and remove dust particles from the pores of the filter.

Parameters of the pulse valve Festo VZWE-E-M22C-M-G34-200-H:

Version: angular shape, diaphragm valve, pulse

Connection: G3/4 internal (pipe, cylindrical)

Valve function: 2/2 N.C., monostable, pulse

Flow direction: irreversible

Working medium: compressed air

Operating pressure: 0.35 ... 8 bar

Ambient temperature: -20 ... +60 °C

Standard nominal flow: 15 m3/hour

Material Information, Housing: Aluminum Die Casting, EN AC-47100D

Valve weight: 0.42 kg

Price: RUB 4,763.64

PNEUMATIC CONTROL VALVE FESTO VZXF-L-M22C-M-B-G12-120-H3B1-50-16

Reinforcement valve with pneumatic control Festo VZXF-L-M22C-M-B-G12-120-H3B1-50-16- This is a poppet valve with an inclined spindle and has external pneumatic control. The valve closing element is directly moved by a pneumatic cylinder. In its normal position, the valve is closed under the action of a spring. When pressure is applied to the cylinder, it lifts the locking disc above the seat and thereby opens the valve. The valve seat is located at approximately 50° to the direction of fluid flow. The direction of flow (from right to left or vice versa depends on the design of the valve. Angle poppet valves are often used in cases of viscous media, steam or when the purity of the working medium is not guaranteed.

Parameters of the Festo VZXF-L-M22C-M-B-G12-120-H3B1-50-16 reinforcement valve:

Version: poppet valve with spring return

Connection: G1/2 internal, cylindrical

Control type: pneumatic, G1/8

Valve function: 2/2 N.C., monostable

Flow direction: irreversible

Working medium: steam, mineral-based hydraulic oil, inert gases, mineral oil, water, compressed air - filtration degree 200 microns, neutral liquids

Operating pressure: 0 ... 16 bar

Max. medium viscosity: 600 mm2/s

Liquid temperature: -10 ... 80 °C

Standard nominal flow: 3.7 m3/hour

Body material: brass

Valve weight: 1.20 kg

Price: 9,886.80 rub.

PINCH VALVE FESTO VZQA-C-M22C-15-GG-ALALE-6

![]()

Pinch valve Festo VZQA-C-M22C-15-GG-ALALE-6 The 2/2 valve is normally closed and is designed to control the flow of various media, both liquid and gaseous, including those with mechanical inclusions. The valve locking element is a cylindrical, hollow elastomer sleeve. When compressed control air is supplied to the valve, it will compress the bushing in the transverse direction, and the bushing will thereby tightly block the flow. When the control pressure is released, the pinch valve will open due to the restoration of the shape of the valve sleeve due to the pressure of the working medium. This pinch valve can be used to control the flow of liquids and bulk materials, pastes and mixtures. The full-flow channel in the open state of the valve provides minimal hydraulic resistance, which prevents clogging or clogging of the pinch valve.

Parameters of pinch valve Festo VZQA-C-M22C-15-GG-ALALE-6:

Version: pinch valve with pneumatic control

Shut-off valve connection: G1/2 internal, cylindrical

Control type: external, pneumatic

Valve function: 2/2 N.C., monostable

Flow direction: reversible

Working medium: compressed air, liquids, bulk materials, pasty substances and mixtures

Pilot pressure: 3.5 ... 6 bar

Max. viscosity: 4000 mm2/s

Operating pressure: 0 ... 6 bar

Ambient temperature: -5 ... 60 °C

Housing material: aluminum alloy, alloy steel, stainless

Pipeline accessories— equipment installed on pipelines and designed to control the flow of working media in pipelines by changing the flow area. Management refers to the distribution and regulation of working environments, as well as their shutdown and mixing. Working media can be liquid, gaseous, powdery, suspension, etc.

Pipeline fittings and equipment are divided according to their functionality into shut-off, control, safety, protective, phase separating and distribution. Let us tell you in more detail about each class of pipeline fittings.

Shut-off valves

Shut-off valves are designed to shut off the flow of medium in a pipeline. Shut-off valves are divided into the following popular types: Ball Valves, various gates, valves, wedge gate valves.

The ADL pipeline valves catalog has the most complete line of shut-off valves for use in engineering systems Housing and communal services and construction, as well as at industrial enterprises. We produce and sell such pipeline fittings as: steel ball valves "Bival", butterfly valves "Granval", check valves "Granlok", wedge gate valves "Granard". The ADL company produces reliable, easy-to-use, durable shut-off pipeline valves for heat supply systems, gas supply, refrigeration, air conditioning and industry.

Control valves

Control valves are a type of pipeline fittings designed to regulate the parameters of the working environment. The concept of parameter regulation includes regulating the flow of the medium, maintaining the pressure of the medium within specified limits, mixing various media in the required proportions, maintaining a given level of liquid in vessels and some others.

Control pipeline fittings can be divided into two groups:

- Direct-acting control valves (the movable element of the valve is driven by the energy of the working medium). This group includes direct-acting pressure regulators, level regulators, etc.)

- Indirect-acting control valves (the moving element of the valve is driven by external energy - for example, electrical energy or compressed gas energy).

Safety fittings

Safety valves are designed to prevent an emergency increase in any parameter in the working environment by selecting excess quantity environment. For example, this function is given to safety valves.

ADL produces pipeline fittings and this type - Pregran safety valves.

Safety valves are designed to protect equipment from emergency excess of any parameter of the working environment (pressure, temperature, etc.) by disconnecting the pipeline section. For example, check valves.

Phase separating fittings

Phase separating fittings are used to automatically separate different phases of the working fluid, for example, water and steam (condensate traps), water and air (air vents), etc.

Distribution fittings

Distribution fittings perform the task of distributing the flow of the medium in two or more directions.

Selection of pipeline fittings

Depending on the class of industrial pipeline fittings and operating conditions, a wide variety of requirements are imposed on its operation, the main of which are strength, long service life, reliability, cost, maintainability, and safety.

To buy pipeline fittings from the manufacturer, contact ADL. Our advantages:

- Application processing within 24 hours;

- assistance in selecting equipment;

- prompt delivery of pipeline fittings;

- flexible discount conditions;

- affordable price of pipeline fittings.

The consequences of a wrong choice can be extremely dire. That is why the selection of pipeline fittings, especially for use on technological lines of industrial enterprises, should be carried out by professionals, or better yet, by the manufacturer of the pipeline fittings themselves. With our equipment, your system will work efficiently and without accidents.