Ball valves in modern world are used everywhere. For example, for installation and connection of water pipes, installation and connection of a boiler, installation of radiators or a heating system as a whole, or connection of water and gas meters, etc. Such products are very popular, but due to the wealth of varieties and sizes, choose the right ball valve happens to be difficult. Therefore, every owner of the house should have at least a rough idea about these products.

Device description

Why is the valve called "ball"? The answer is simple - there is a metal sphere inside the device. When turning the valve it allows or blocks the passage of water or gas through the pipes. Such a locking device is especially popular in private houses or apartments.

Why is the valve called "ball"? The answer is simple - there is a metal sphere inside the device. When turning the valve it allows or blocks the passage of water or gas through the pipes. Such a locking device is especially popular in private houses or apartments.

Depending on the manufacturer, as well as on the purpose of use, the dimensions of ball valves may vary, so this must be taken into account when purchasing. But nevertheless, if we compare the dimensions of modern products with those that were produced 10 years ago, then the current ones will be much more compact, more reliable and more functional than their predecessors.

Each device has the following details:

- Frame. In it and is a metal sphere, which prevents or facilitates the passage of gas or water.

- The twisted part. Thanks to it, if necessary, you can disassemble the ball valve.

- The working part, that is, a metal ball.

- Seals. In order for a metal sphere to fit snugly, various materials are required that contribute to this.

- Actuating stem - reduces effort when turning the valve.

- The control lever is the valve itself.

The safety margin of the products is designed for strong fluid flows that will constantly pass through the ball valve. Therefore, such devices can be fearlessly placed even in the most "water-pressurized" places.

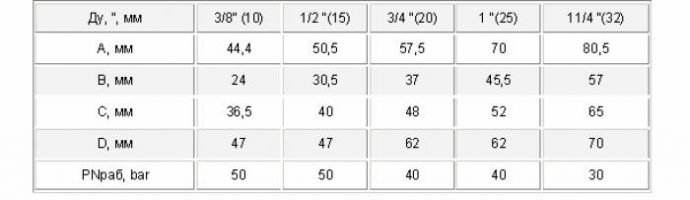

Characteristics and dimensions

As mentioned above, before buying it is recommended to familiarize yourself with the sizes. locking devices. For example, the classification of ball valves for water is based on the diameter of the passage inside the product. In addition, the devices differ in the type of threaded coating and operating pressure indicator.

As mentioned above, before buying it is recommended to familiarize yourself with the sizes. locking devices. For example, the classification of ball valves for water is based on the diameter of the passage inside the product. In addition, the devices differ in the type of threaded coating and operating pressure indicator.

Knowing the size of the internal passage of the ball valve purpose and frequency of use can be determined locking mechanism. So, mechanisms with a size of 1, 1.25 or 1.5 inches indicate infrequent use and are not designed for constant loads. Otherwise, the device will fail.

In everyday life, products with a diameter of 0.5 (about 12.5 mm) or 0.75 inches are used. The first option is great for water supply, and the second for heating systems with a circular pump. If the circulation is based on the natural working environment, pipes with a diameter of 40-50 mm will be required. Otherwise, you can get by with narrower products.

Of course, there are other models with an even larger diameter, but they are installed purely in production or at special facilities. In everyday life, products with a diameter of 0.5 to 1.5 inches are quite enough.

Marking

On closer examination of the ball valve, you can find some symbols on it. These signs carry a lot useful information

like tags on clothes. The ability to decipher this data will allow you to understand whether this device is right for you.

On closer examination of the ball valve, you can find some symbols on it. These signs carry a lot useful information

like tags on clothes. The ability to decipher this data will allow you to understand whether this device is right for you.

Marking is regulated by GOST R 52760. The document says that the manufacturer is obliged to indicate on a prominent part of the product or on a separate plate the information necessary for the buyer. As a rule, the following data is indicated on ball valves:

- DN - directly, the diameter of the internal passage.

- PN - maximum pressure value. As a rule, it is indicated in atmospheres.

- Design and operating pressure values.

- The material from which the body of the ball valve is made.

- One or more arrows indicating the direction of flow.

- The minimum and maximum temperatures at which the device can operate.

- Manufacturing date.

The best materials and manufacturers

The metal or alloy from which the ball valve is made plays a significant role in its use. Poor quality material can break the device in the shortest possible time. As a result, a broken product will cost the financial cost of replacing it.

The metal or alloy from which the ball valve is made plays a significant role in its use. Poor quality material can break the device in the shortest possible time. As a result, a broken product will cost the financial cost of replacing it.

Ball valves are usually made of brass or nickel-plated brass. These materials have proven themselves for a long time. However, it is not recommended to purchase products, the material for which was silumin. Cranes made of silumin may crack or literally fall apart during installation, especially if they were made by an unscrupulous manufacturer.

ValTec is the undisputed leader in the ball valve market. It has long established itself as a quality and reliable manufacturer of sanitary ware. Therefore, first of all, it is worth focusing on the products of this company.

If there are no models from ValTec, you can purchase devices from Bugatti. She also is of excellent quality, but is present in the plumbing market less than its competitor. Domestic producers also want to take the lead. For example, the Bologovsky Valve Plant, which, after "stagnation", is trying to make up for lost time due to low prices and high-quality products.

The high demand for ball valves has had a significant impact on the variety of products, the level of competition and the quality of products. But, despite the rich choice, it should be remembered that for each purpose there is a crane of a certain size. Therefore, when buying, you must be guided by this principle.

Purchasing a product of the wrong diameter can cost you nerves, time, and possibly money. Therefore, choosing a model for heating, you should not aim at sizes of 1-2 inches. Otherwise - a return request, extra running around and again searching for a suitable product.

After deciding on editing in the heating or water supply systems, connecting water or heat meters, then without using stop valves not enough. As it is desirable to use ball or plug valves. Before choosing the type of valves, it is necessary to understand what requirements it must meet. That is, it will be necessary to determine such parameters as the size of ball valves, the material and type of valve connection.

The dimensions of the ball valve consist of thread parameters, dimensions.

One of the key characteristics of a ball valve can be called the internal (through) diameter. Other parameters include operating pressure and temperature. Of course, these parameters are determined by the material from which the cranes are made. An important role is also played by which company produced these products.

As an example, you can study the most commonly used ball valves in everyday life. Namely, when arranging engineering parts in an apartment building or a private house. Practice shows that when arranging such systems, cranes with different geometric parameters are used.

In particular, when setting up engineering systems use ball valves with bore diameters, inch. In addition to those indicated, taps with a diameter of 1.1 ¼ 1 ½ inches are used. For example, when creating engineering networks V country house it is enough to use fittings with a diameter of half an inch. For the heating system, the best option would be to use fittings of three quarters of an inch. If the system is built on the basis of the natural movement of the coolant, then it makes sense to increase the diameter of the pipes and valves used to two inches.

IMPORTANT! “Yuri Nikolaev: How I got rid of alcohol addiction in 7 days…

But, of course, when choosing pipes and valves, it is necessary to be guided by the results of the calculations, which should be part of the project. Most manufacturers put markings on the surface of the faucet body, in which the installer will always see what are the dimensions of the faucets required for network installation.

The marking, as a rule, looks like this DN (nominal diameter) 15, it means that the tap has an internal (through) diameter of 15 mm, or about one second of an inch. The second digit under the designation Pn indicates the working pressure for which this shutoff valve is designed.

Documentation regarding ball valve dimensions

GOST 21345-2005 defines the ratio of the nominal diameters of ball valves and the pressure at which the operation of this type of product is permissible. So, for example, valves with DN20 can be installed in a network with a nominal pressure of the working medium of 17 MPa. It should be noted that in GOST there is a division into through passage and partially through passage cranes.

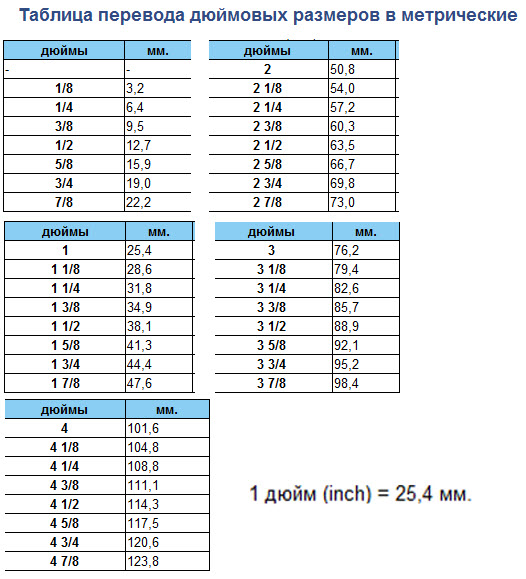

Historically, all sizes of diameters, internal and external, the nominal parameters of the thread are measured in inches. That is, in the system of measures that is adopted in some countries. To convert inches to familiar millimeters, you can use the following ratio - one inch is equal to 25.4 millimeters. You must understand that this is a very conditional ratio and when placing an order, the dimensions for ball valves are in inches and not in millimeters.

In the same document there is a reference to GOST 28338-89, which defines the dimensions of the diameters that are used in the design and manufacture of shut-off and other valves. In fact, these two and several other regulatory documents are the main ones for designers of thermal and water networks for multi-apartment and private houses.

By the way, the calculation of the nominal diameter of the pipeline is determined at the design stage of the network, based on the heat load, the required parameters of temperature, pressure and the flow rate of the working medium. The calculated diameter of the pipeline is the reference point from which the brand of valves is selected.

The dimensional characteristics of a ball valve include the type of thread and its location. Both external and internal threads are used in taps. Valves with a thread applied to the outer surface are called a nut-nut, if the thread is applied to the inner surface, then such products are called a fitting - fitting.

Construction length and height

Another dimension that is directly related to the valves is the construction length. The definition of this term is as follows: this dimension shows the length of the pipeline section that will be replaced by shutoff valves. That is, this is the distance from one end of the crane to the other. Construction height is the distance from the lowest point of the crane to the highest. In other words, these are the overall dimensions.

These dimensions must be taken into account by the designer when designing the pipeline system. In addition, he must install a ball valve with dimensions that provide free access to it for maintenance and repair. In addition, it is necessary to provide access to fasteners for assembly and dismantling.

The size of the construction length is determined by GOST 3326-86. So, for example, a crane, DN20, designed to work in pipeline system with pressure Pn 4 MPa has a construction length of 150 millimeters.

By the way, the construction length is measured only in millimeters, in contrast to the diameters of the through holes and thread ratings.

In this article we will talk about the main differences between the inch system of measurement and the metric one. We will also consider the features of the choice of valves for the pipeline.

The topic of the article is of considerable interest, since the market offers a wide range of plumbing equipment, the dimensions of which are not determined in the usual millimeters. For example, you can find a half-inch faucet on sale, and what do you think this size means?

Measuring difference

In order to immediately clarify the difference in measurement values, we note that the inch measurement system is traditionally used in the construction of pipelines and in the selection of valves.

The English inch (inch) is denoted when written as ", equal to 25.4 mm in the metric system of measurement. Thus, it is not difficult to convert the modern values \u200b\u200bused at into millimeters; it is enough to arm yourself with a calculator.

For example, let's calculate which analogue of the metric system of measurements corresponds to a 2-inch tap. To do this, multiply 25.4 by 2 and get 50.8 mm.

So, the calculation instruction is theoretically simple, and it is also simple to calculate the dimensions of an inch crane. It remains to consider how these values are combined with the size of the pipes.

Features of the pipeline diameter

Currently, when building intra-house water supply networks, the most popular solution is metal-plastic, polypropylene, less often completely metal.

It is no secret that all these pipes with a similar outer diameter will have a different inner diameter, since steel pipe will be thinner than a similar product made of polymeric materials.

Therefore, when determining the dimensions of the pipeline and its compliance with the dimensions of the valves, the following values should be taken into account:

- wall thickness;

- inner diameter- conditional characteristics of pipeline elements, both pipes and fittings;

- nominal diameter(Dу) - the nominal value of the internal diameter, indicated in millimeters and rounded to the nearest integer;

- nominal diameter Dn;

- outside diameter.

From the foregoing, it follows that if the valve is 1 8 inches (inner diameter) with internal thread mother, then the outer diameter of the pipe with an external thread should also be 1/8″.

Accordingly, we look in the previously given table, how much 1/8 ″ will be and see 3.2 mm. That is, we got the diameter of the inside of the faucet and the outside of the pipe in millimeters.

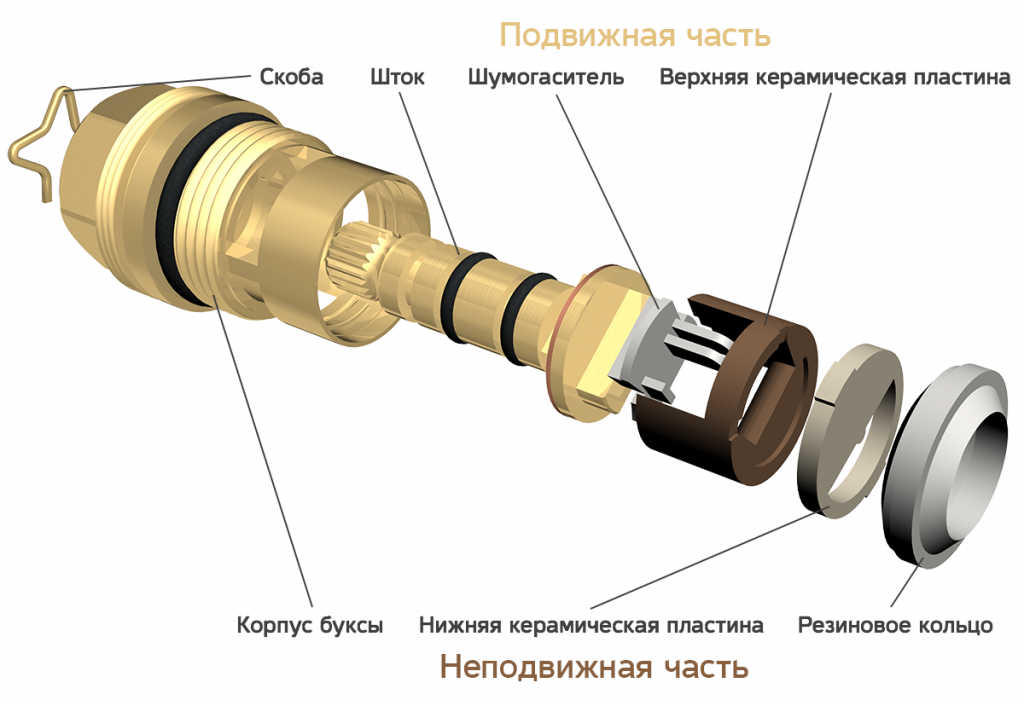

Inch ball valve device

![]()

When we say an inch and a quarter tap, we most often mean the so-called half-turn shut-off devices with a ball-type gate. Consider how such equipment is arranged, and what you need to keep in mind when choosing it.

A ball valve is a type of pipe fittings, the locking element in the design of which is made in the form of a sphere.

To date, half-turn valves with a spherical gate are considered one of the most modern, progressive and at the same time easy to install and maintain types of valves. Such cranes are widely used in the arrangement of pipelines transporting liquid and gaseous media.

The movable spherical valve has a through axial hole, which in a certain position coincides with the through hole in the valve body. When the holes match, the flow of water passes freely, at the same time, if the holes in the body and the valve do not match, the flow is blocked. For example, the valve will be completely closed if the ball is rotated 90 degrees around its axis.

A full bore valve is equipped with a gate sphere with a through hole diameter similar to the inner diameter of the branch pipe that is connected to the pipeline.

By matching the parameters of the hole to the parameters of the pipeline, the level is minimized hydraulic losses, which distinguishes these devices from other types of valves. Therefore, the ball valve is currently used as the main type of shut-off device in the linear sections of gas pipelines.

An important element in the design of a ball valve is the "saddle" made of fluoroplastic rings. The presence of "saddles" provides a full-fledged adjoining of the shutter and the body, tightness, smoothness and ease of turning the plug.

Important: The presence of fluoroplastic seats limits the temperature of the transported medium to + 200 °C.

Summing up the foregoing, we note the advantages characteristic of ball valves:

- simplicity of the device;

- tightness of the body and shutter;

- compact dimensions;

- simplicity of the configuration of the flow path and the almost complete absence of stagnant zones;

- ease of management;

- limited time required to complete the rotation of the shutter;

- possibility of operation when transporting viscous media, sludge, suspensions, pulps, etc.

Important: Such devices are characterized by one significant drawback - the presence of a "dead" zone when turning the shutter with a cantilever flywheel.

This inconvenience is fully compensated by a crane equipped with a lamb flywheel.

The device and operation of the valve valve

Along with shut-off valves, it is impossible not to note the presence of valve cocks, which are widely used in the construction of domestic and industrial pipelines.

Among the advantages of this type of valves, we note the following:

- high degree of maintainability in comparison with ball counterparts;

- affordable price;

- a wide range of offers due to the variety of modifications;

- ease of installation;

- the possibility of using it as shut-off and control valves (for comparison, a ball valve is only shut-off valves).

Among the shortcomings, we note less durability in comparison with spherical counterparts. On the other hand, if necessary, the device can be disassembled, find out the cause of the breakdown and repair it yourself.

A conventional single-valve faucet consists of the following structural elements:

- housing made of copper, brass or of stainless steel;

- spout (separate or inseparable from the body);

- flywheel mounted on the rod;

- the locking mechanism is a worm or ceramic type crane box.

As already mentioned, two types of locking mechanisms are used in valve-type devices. Consider the features of their application.

![]()

In the photo - a worm-type valve valve box

The worm-type locking mechanism is driven by several turns of the flywheel around its axis. The worm rod at the end opposite the flywheel is equipped with a rubber or leather gasket.

The gasket in the process of rotation is adjacent to the "saddle" and thus the water supply is blocked. Conversely, if you rotate the flywheel in the opposite direction, the gasket moves away from the "saddle" and the water passes unhindered.

Important: The most common problem in such mechanisms is the thinning of the gasket and, as a result, the occurrence of leaks.

The repair instructions are simple, just disassemble the faucet, remove the old gasket and install a new seal in its place.

The locking mechanism in the form of a ceramic crane box is a more progressive option, in comparison with a worm-type device.

The shutter is a core with two combined ceramic plates, one of which is fixed, and the second rotates around its axis. In the process of turning the rod, the plates are combined or, conversely, a gap is formed between them, through which a stream of water passes.

Among the advantages of this type of shutters, the following should be noted:

- low torque, since the devices are half-turn;

- shutter durability due to the fact that ceramic parts are an order of magnitude stronger than a rubber gasket;

- ease of repair, since the shutter is not repaired, but changes entirely, despite the fact that its price is low.

Conclusion

So, now we have a general idea of what a 3 4 inch faucet is and similar products with other sizes. Again, we examined the features of the device of locking devices adapted for mounting on inch pipes.

Any questions left? You will find more comprehensive answers by watching the video in this article.