The ESBE three-way valve is just one of the elements of the life support systems of a residential building. On the one hand, this is a simple design. On the other hand, it performs an important task in engineering networks. Demand creates supply. There are many models on the market from different manufacturers. Three-way valves manufactured under the ESBE brand are distinguished by good performance.

Some useful knowledge

Three-way butterfly valve ESBE

The three-way valve is a control device in piping systems with a liquid working medium. talking plain language, built into the design of the heating network, it will act as a well-known mixer tap that switches or mixes flows. Installing the valve allows you to solve a number of practical problems:

- Redirection of flows coming from different pipelines.

- Achieving the desired temperature of the working fluid by mixing hot and cold flow.

- Obtaining a jet with a constant temperature by dynamic redirection.

Difficult? Only at first glance. In order to understand the principle of operation of the device, consider its design features.

Design

A three-way mixing valve has a control element, which is a stem or a ball. The rod moves vertically, the ball moves around its axis. Since the movement of the regulating element does not allow to completely block the flow of the working fluid, it is mixed and redistributed. The simplest models are an ordinary crane. Their main advantage is low cost and constructive simplicity. The disadvantage is the impossibility of stabilizing the outlet temperature. Despite the shortcomings, the tap can be installed in underfloor heating systems. Now imagine a motorized valve. This design is already more functional, as it is able to regulate the temperature automatically. A simple valve is a balancing valve. Its main function is to adjust the section for the passage of the work stream. Conventionally, the principle of its operation can be described as follows:

- The handle is turned by 50% - uniform mixing of the two streams, since the inlet valves will be equal.

- The handle is turned 100% - the first valve is fully pressed and blocks the movement of the fluid flow.

The modifications presented on the market may have different handle turns, but the principle of their operation is preserved. The valve and its position are adjusted manually, thereby ensuring a balance between the two streams.

Kinds

There are several types of such devices:

- With hydraulic drive.

- With pneumatic drive.

- With electric drive.

A motorized three-way valve, such as the ESBE model, will have a slightly different operating principle. The electric drive performs the function of a conventional thermostat, which makes it possible not only to mix the flows, but to maintain the set temperature. When the temperature drops / rises, the actuator automatically changes position stop valves, increasing or decreasing the flow cross section hot water. At the same time, the cross section at the cold flow inlet also changes. The result is water with a constant temperature. The ESBE crane does not require any human intervention. Its work is regulated by automation.

![]()

Valve principle

Equipped with electric actuators and thermostats, ESBE valves are equally well suited for use in heating and hot water systems. In principle, the valve can be installed in any pipeline where it is necessary to mix two fluid streams with a constant temperature. No matter how high-quality and reliable a three-way valve with a thermostat is, it will have one drawback that is characteristic of absolutely all devices of this type.

Such a disadvantage is the strong narrowing of the entry points. The narrowed section of the entry point, in turn, increases the hydraulic resistance.

Such a faucet will work well in water supply systems. ESBE dampers are suitable for installation in underfloor heating systems, but a special wiring diagram is required. In addition to the designs described above, three-way thermostatic valves are on the market. These devices are often confused with each other, but still they are completely different. Thermostatic models have a thermostat with a remote sensor, but they differ not only in this element, but also in the principle of operation. Unlike conventional models, in thermostatic taps, the flow is regulated only at one point, the remaining two are open, and their cross section does not change. When choosing such a design, you need to check if there is a narrowness at point 2, otherwise hydraulic resistance lead to problems with the operation of the device. It may be necessary to install a mixing valve in an alternative ring to minimize the problem.

Wiring diagrams

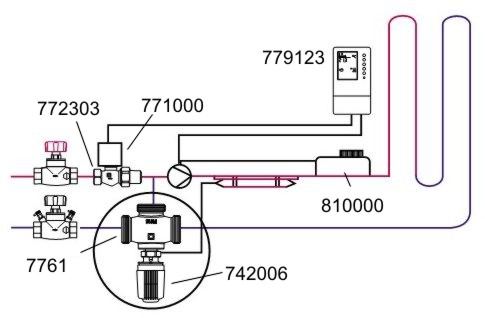

Three-way valve - switching circuit

Almost all three-way valves on the market are connected in the same way. Consider it on the example of ESBE cranes. Let's start with water supply systems, since here the mixer tap is used most often. The main purpose for which the valve is installed is to reduce the risk of backflow. Between the two streams - with cold and hot water - there will inevitably be a pressure drop. It can lead to reverse flow. When installing ESBE valves, such incidents are rare. In heating systems, ESBE valves are used only in three directions:

- In mixing units of "warm floor" type systems.

- To stabilize the temperature of the liquid flow in the inlet pipeline of the boiler.

- To reduce the supply of high temperature coolant from the boiler to the pipeline.

Valve in the mixing unit

Consider how the ESBE crane is used in underfloor heating systems. The mixing unit creates an additional circuit in the system. It is connected to the distribution manifold at two points, which ensures constant circulation of the liquid at the outlet. At the inlet, the flow is provided only if additional heat is needed. A valve with a thermostat is connected to the mixing unit. Since at point 2 all valves, including the ESBE, are narrowed, insufficient pump flow can be observed. To increase it, a second line is being created, which makes it possible to reduce the consumption of electricity by pumping equipment. The second line is not always required. Some models of three-way valves have sufficient orifice.

Scheme of a warm floor with a three-way valve

In the event that there is insufficient flow power on the first line, the thermostat will not be able to open the passage to the required value. The problem is easily solved in two ways: narrowing the second line or installing a balancing valve on it. The second way is more productive. It allows you to fine-tune the flow. You can connect a three-way valve according to another scheme that does not require the installation of a balancing valve. For this pump equipment connected to the second line. As a result, the temperature of the inlet and outlet streams is compared. A thermostatic valve can be installed in systems with a single circuit. The simplest example of such systems is underfloor heating in small rooms. The creation of a mixing unit here, with its considerable dimensions, is far from always justified. It is better to connect a warm floor with one circuit. A three-way valve with a thermostat is installed on the return line, through which the already cooled coolant flows. In this case, the thermostat will move the stop valves, increasing the cross section and opening the flow. After heating the pipe, the temperature sensor reads the data and reduces the flow.

For heating boilers

Heating should be considered separately. The main task of their installation is to prevent a cold flow of coolant to the incoming pipeline connected to the boiler. Otherwise, condensation will begin to form on the pipes, and temperature changes in the system will lead to its deformation at the joints. There is no need to talk about the consequences of such deformations. At best, a small leak forms, at worst, the system will have to be completely changed.

Three-way valve in the heating system

It is especially important to connect shut-off valves to solid fuel boilers characterized by significant temperature differences during operation. Connecting the mixing valve allows you to ensure that no liquid enters the inlet of the boiler equipment, the temperature of which is below 50 degrees. As a result, the temperature difference decreases negative impact cold with all the ensuing consequences is reduced. It is recommended to install mixing valves in systems with plastic piping. Here the goal is to prevent high temperature coolant from entering the pipeline. With all the advantages of polymers, they do not withstand the frequent increase in temperatures above operating parameters. Under such operating conditions, the pipeline is rapidly destroyed. Temperature indicators recommended by experts range from 75 to 85 degrees. The installation of valves solves many problems, but the model must be selected exactly according to technical specifications engineering network, and must have sufficient passage.

Conclusion

The simplest shut-off valves - three-way mixing valves- an important element of engineering communications. Modern models created at the junction of old traditions and modern technologies, allowed to achieve excellent results of their use with a variety of purposes.

Similar posts

A three-way thermostatic mixing valve is a product whose purpose is to provide the ability to control and maintain the set temperature of the coolant in the heating system. A feature of the device is that it is equipped with one input and two outputs or two inputs and one output. This design allows you to install a three-way valve for the boiler at branch points or where it is necessary to ensure the mixing of the coolant, for example, hot and cold water.

A wide range of products in GSCM

Our company specializes in the implementation various kinds shutoff valve. This section presents three-way thermostatic mixing valves from well-known manufacturers such as: HERZ, UNI-FITT. All fixtures are made of high quality brass alloy. Among the main characteristics - reliability and resistance to corrosion. In addition, they are sold at affordable prices.

We offer many types of three-way valves with threaded connection type (M/F, M/N). This makes it possible to select products for any type of heating systems. It should also be noted that each device is equipped with a special valve, with which you can set the necessary modes, thereby making fine tuning.

How to purchase a three-way thermostatic mixing valve

To buy the selected product, you must add it to the shopping cart and complete the purchase. If you encounter difficulties in choosing, we recommend that you contact our operators for help. You can contact us by phone or e-mail. Ask questions of interest online in a special form. Contact details are listed in the relevant section.

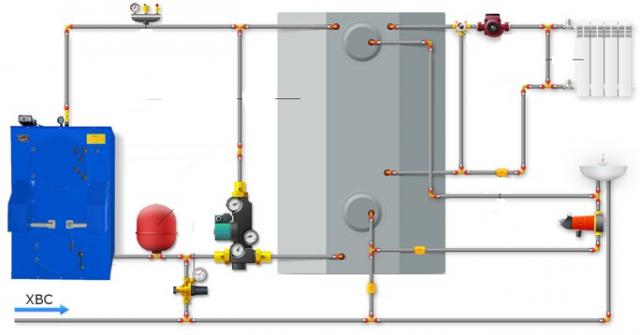

The three-way valve for underfloor heating is a key part of the mixing unit of the water heating system. The scheme of such a heating system consists of a boiler that heats the coolant, several circuits with high-temperature radiators and pipeline circuits for a water-heated floor.

In most cases, boilers heat water to the temperature required by high-temperature radiators. As a rule, it is equal to 75-95 ° C. Taking into account sanitary standards, the surface of a warm water floor should not have a temperature above 35 ° C. This temperature ensures a comfortable stay on the floor, in addition, a higher temperature of a water-heated floor can have a destructive effect on the finish coating - especially on laminate or linoleum, and lead to its deformation.

Taking into account the thickness of the warm water floor screed, in which the pipes of the heating circuit are located, as well as the thickness and type of floor covering, the temperature of the heat carrier should be about 50 ° C. If the water-heated floor is connected to a centralized heating system or water comes directly from the boiler, then its temperature will be too high.

To lower the water temperature in the system, at the entrance to the heating circuit of a water heated floor, a mixing unit, which has a two-way or three-way valve. They mix the hot and cold coolant coming from the return circuit of the water-heated floor.

During the passage of water through a two- or three-way valve, the temperature decreases and becomes suitable for the system - a coolant with a temperature of 90-95 ° C enters the heating radiators, and a temperature of 50-55 ° C enters the heating circuit of the underfloor heating water system.

When the heated coolant enters the collector, it is blocked by a safety valve equipped with a thermostat. If the coolant temperature is higher than required, then the two-way or three-way valve will work, which will lead to the supply of cold water from the return circuit. Mixing will be performed, the hot and cold coolant will mix, and when the temperature reaches the desired value, the tap will work again and the hot water supply will stop.

The device and principle of operation of the two-way valve

H2_2

In most cases, a two-way control valve is used in a water-heated floor system. This type of control valve ensures the correct regulation of the flow and pressure of the coolant and the cooling medium.

If necessary, the device is able to maintain the temperature of the water in the pipeline of a warm water floor at a constant level. A two-way valve provides periodic replenishment of the pipeline with a coolant heated to the desired temperature coming from the heating system.

The temperature of permissible heating is indicated on the faucet body, which can be changed using a built-in or remote sensor. The remote temperature sensor is mounted in the inlet manifold. The operation of a two-way valve is simple:

- The coolant exits the return circuit of the water-heated floor and circulates through the pipeline.

- When the water is cooled below the specified level, the valve is activated and a hot coolant is mixed into the system.

- After the temperature reaches the set point, the valve stem closes.

Important! Two-way valves are used in underfloor heating systems that heat an area of less than 200 square meters. m. If the room is with a larger quadrature, then the thermostat will often signal a decrease in temperature, since the water will constantly cool down as it moves along a long line. Because of this, the two-way valve will constantly replenish it with high-temperature coolant.

There are the following types of two-way mixing valves:

- Pneumatic;

- hydraulic;

- With electric drive.

A two-way faucet for warm water is made of cast iron or brass, it can be equipped with an electric drive.

A two-way valve design may have one or two seats. A two-seated product can, if necessary, completely shut off the flow of the coolant; a three-way valve cannot perform such a function.

The principle of operation of a two-way valve is that when a mechanical force is applied to the actuator, it is transmitted to a congestion consisting of a seat and a plunger. Moving down, the plunger closes the internal space of the valve, in the process the coolant flow increases, and the pressure decreases. If the shutter is fully lowered, the valve will close hermetically. This will stop the coolant flow through the line after locking device. Plungers can be needle-shaped, rod-shaped and disc-shaped, the axis of movement of the plunger is perpendicular to the water flow.

A two-way valve can be connected to a water floor heating system using a parallel circuit. Such a connection scheme is implemented in the process of using two or three heating circuits through which the coolant circulates.

In this case, the adjustment of the water supply and pressure will be carried out exclusively with the help of one or more two-way valves installed in parallel. If a parallel method of mixing the coolant is used, then the underfloor heating pipelines are initially disconnected.

The two-way valve can be manually adjusted to allow the right amount of water to pass through the mixing tap. The presented scheme does not include a three-way valve equipped with a temperature sensor - such a shut-off element has a small throughput, in this case a two-way valve does an excellent job of adjusting.

Advice! In a parallel circuit, it would be appropriate to install a bypass valve instead of a bypass. This will reduce the operating load and reduce the power consumption of the pump while the circuits are closed.

The parallel connection scheme has a drawback - the temperature mark of the coolant that enters the circuit is equal to the temperature of the water flowing from the return circuit to the boiler. This leads to an uneven distribution of hot water along the circuits. The parallel circuit consists of the following elements:

- Collector and heating pipes;

- Shut-off and control valves - dampers or two-way valves;

- A circulation pump that pumps the heated coolant from the boiler through the heating circuit;

- Control unit.

Features of the three-way mixing valve

The three-way mixing valve ensures the operation of the water-heated floor in a comfortable mode. The locking element mixes the hot coolant coming from the boiler with cold water from the reverse circuit. The three-way valve, despite its versatility, has several disadvantages.

So, for example, when receiving a signal from the thermostat, the device for supplying heat carrier from the boiler opens completely. Because of this, water with a temperature of 85-90 ° C enters the underfloor heating system and can cause overheating of the surface or rupture of the pipeline.

In addition, a three-way valve has a lower throughput compared to a two-way valve, which leads not to a flat, but to a wavy graph of heat carrier temperature fluctuations. The device is adapted for systems with a heating area of more than 250 sq. m.

The three-way valve is made of bronze or brass, in its upper part there is a washer for adjusting the flow, under which there is a temperature-sensitive element. When the valve is in operation, it is pressed against the working stem that emerges from the body. There is a fixed cone in the stem, which hermetically adjoins the seat. The scheme of operation of the three-way mixing valve is simple - the coolant passes through the right and front pipes until the temperature mark rises or falls to the set value. During operation, the device maintains the desired outlet water temperature within the established limits and mixes hot or chilled water from the nozzles.

If the coolant begins to cool or heat up, then the drive is pressed against the rod. In the process of moving, the cone is disconnected from the seat and opens all three channels. The front inlet pipe is blocked after the temperature indicators of the coolant change.

Three-way valves differ in the type of external actuator. They can be equipped with:

- Thermostatic drive. It presses the rod in the process of expanding the liquid composition in it, which is sensitive to temperature changes. Most three-way valves used in underfloor heating systems are equipped with this type of actuator.

- A thermostatic head that contains a highly sensitive thermocouple that reacts to temperature changes in the room air. To carry out the adjustment, the three-way valve is equipped with an external temperature sensor. The sensor is placed in the pipeline through which the coolant passes. This adjustment is the most accurate.

- The electric drive controlled by the controller. The controller continuously receives data on the value of the temperature of the coolant in the pipeline of the water floor. If they change, the servo-equipped three-way valve makes the adjustment.

- Servo. There is no controller in such a locking mechanism, and the valve is controlled directly through the actuator based on signals from temperature sensors. The servo drive is in most cases completed with cranes that are equipped with a sector or ball distribution element.

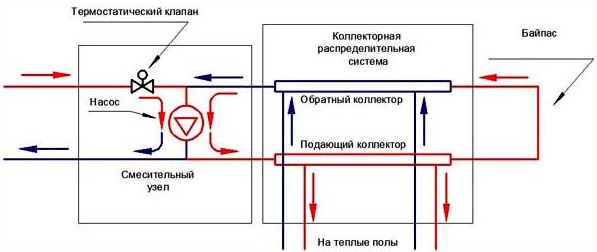

The three-way valve is connected to the water heating circuit with a series orientation. Such a scheme is considered the most productive, in which the thermostatic valve can be replaced by a balancing valve or a conventional ball valve. A ball valve is the cheapest and most economical unit, but if installed, the operation of the system will have to be controlled manually.

The serial connection scheme functions as follows:

- A three-way shut-off element blocks the supply of cold water from the return pipeline. This avoids the formation of condensate on the inner surface of the walls of the boiler or boiler.

- Water circulates through the primary circuit until it warms up to the temperature that was set on the thermostat of the three-way valve.

- When the coolant is heated to a predetermined temperature, the thermostat causes the stem to open slightly and supply cold water from the heating system.

For hydraulic adjustment within such a system, a balancing valve is used, which is attached to a small circuit.

Important! In a serial connection, the circulation pump is mounted after a three-way shut-off element.

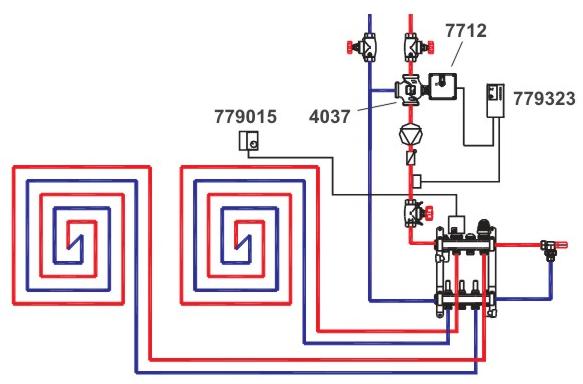

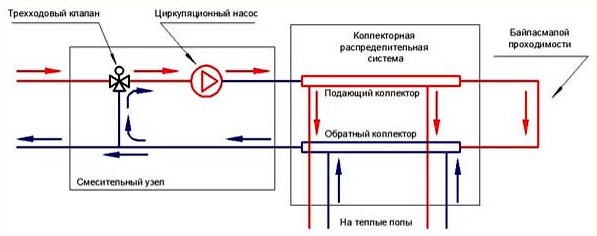

The presented scheme can be continued by connecting a secondary circulation circuit. Connection is carried out according to the following algorithm:

- A three-way valve located in the secondary circuit supplies the mixed water to the circulation pump.

- The pump directs the coolant through the manifold distribution system throughout the circuit.

- Once in the bypass, the coolant is distributed directly to pipeline system warm floor.

- From the system, chilled water again enters the mixing unit and the cycle repeats.

To date, heating with radiators is not enough to comfortably heat the room. In poorly heated houses, additional heating systems are installed. Thus, warm air is evenly distributed and significantly increases the degree of heating of the rooms.

There are several alternatives to classic heating - these are underfloor heating or baseboards. High tech allow you to carry out other heating systems, both as additional and main ones. Warm floors, in turn, can be divided into electric and water heating systems. The latter are in great demand, as their pricing policy is more democratic. Energy consumption is reduced by this type of heating.

Laying a warm water base is accompanied by many mechanisms, valves and taps. It can be compared with any heating system only in smaller dimensions. In order for the underfloor heating to work, it must be correctly connected. Connecting the system is reduced to the presence of:

- Boiler.

- pump.

- thermostatic valves.

This simple circuit complemented by all sorts of mechanisms, taps and valves. The most important point of connecting a warm floor is correct installation and a competent choice of mixing valve. It is from him that the efficiency of the heating system and energy savings will depend.

How does a mixing thermostatic valve work?

The essence of the device, by and large, comes down to mixing a hot stream with a warm one, thereby regulating the floor temperature. A three-way valve is installed to distribute the flow of the working fluid to two circuits. The stem of the three-way design is constantly in the open state. It is adjusted to the regulation of a certain volume of liquid. Due to this, it becomes possible to obtain a qualitative and quantitative volume of liquid in the desired size.

The three-way valve is capable of shutting off variable flow. This makes flow and pressure adjustment possible. A three-way valve equipped with an electric actuator is much more functional. It is able to automatically adjust the temperature. It is these devices that are commonly used when connecting a warm floor.

Mixing taps are divided into hydraulic, pneumatic and electric. The last three-way valve is distinguished by an additional electric drive, the equipment of which includes a thermostat. It allows not only to mix the flows of the working fluid, but also to maintain a given temperature regime.

With an increase or, conversely, a decrease in temperature, the position of a special device - shutoff valves automatically changes. The gap for the passage of hot flow either decreases or increases depending on the problem. The same thing happens with cold water. Thus, the flows are regulated, the output is a liquid with a constant temperature.

In addition to the electric valve, it is very popular thermostatic three-way valve. Many do not distinguish between the above mentioned type and thermostatic. However, the principle of operation of a three-way design of this type is different. This type assumes the presence of a thermostat and a remote sensor.

The three-way mixing valve works in a different way. The fact is that the temperature control of the flows is carried out at one point. The remaining two outlets are constantly open and do not participate in the regulation of flows, since their sections are static. When installing this type of product, you should pay attention to such a nuance as the narrowing of the points. If there are any, then there may be problems with hydraulic pressure. Always pay attention to this moment.

Switching on the three-way thermostatic valve

The design of the valve includes a special thermal head and a separate temperature sensor. These additional elements allow you to adjust the temperature. Thus, a constant temperature is achieved in the system. The pump carries out the movement of fluid in the pipes, and the three-way valve mixes a certain amount of hot flow into the comb.

A three-way mixer is installed at the return outlet. It is worth noting that this classic valve switching scheme may include an additional circulation pump. Otherwise, the heating of the warm floor will be insufficient. This circuit does not work well without a pump.

Small heating areas

If it is decided to carry out a warm floor in a small area, the installation of full-fledged mixing equipment is impractical. You can choose an alternative mixing method.

Special simple equipment for underfloor heating is purchased, consisting of a thermostatic valve with a thermostat and two shut-off valves. The device is closed with a special box. The principle of operation of the equipment is as follows:

- A special handwheel located at the bottom of the valve controls the counter temperature regime. It regulates the optimal temperature conditions of the base.

- A jump in a given temperature threshold serves as a command for the sensor. He closes the valve.

- The design of the valve implies the presence of a touch sensor. He is able to track any temperature fluctuations in the atmosphere. Threshold exceeded set temperature allows the sensor to close the valve.

This is how the product will work in conditions of a small heating area.

large areas

Installing a warm floor as the main type of heating involves the installation of full-fledged mixing equipment, which is able to dilute the flows into two - a warm floor and central heating. Three-way thermostatic valves with full flow into the system are needed here.

Experts recommend installing one common circuit where the working fluid is pumped by a pump. At the entrance to the warm floor, a mixing valve crashes. It is controlled by a special temperature controller. The mixing valve is installed between the bypass and the return. A sensor at the top of the valve regulates the set temperature.

If the temperature rises, the mixing valve closes the return flow. Further circulation of the working fluid occurs in the heat carriers of the warm floor.

If a base with a large number of contours is mounted, it is more expedient to divide the premises into certain sections. In these areas, the connection to the boiler can be made either with a three-way thermostatic valve or with a special device for underfloor heating.

An acceptable alternative is to mount one common mixing unit. This approach requires the valve to be compatible with the controller and actuator. The second allows distinguishing the boundary temperatures of the pipes. The working fluid enters the distributor or a common manifold. Temperature control is possible in this case with the help of remote thermal heads.

![]()

Which manufacturer to choose when buying a three-way valve?

The modern market offers a wide range of products. It is necessary to build on the general parameters of the valves:

- The type of valve itself.

- Valve assignment (e.g. for warm ground)

Based on their general parameters, you can determine the brand and cost of the product. On Russian market brand valves are very popular Esbe(Esbe). This is a Swedish company that has been producing similar equipment for over a century. Trust and reliability accompanies the brand at all times. The choice of equipment of this company will be able to guarantee flawless and durable operation.

Particular attention should be paid to the equipment of an American company. Honeywell (Honeyvel). The products are high-tech, simple and convenient. Installation and use of products for the warm base of this company is not difficult. Innovations are introduced into the technological process of manufacturing equipment every year. Constant updates allow you to achieve maximum efficiency in the operation of products.

IN Lately brand valves became popular Valtec(Valtek). This company manufactures its products in cooperation with Russian and Italian specialists. The products are of high quality and reasonable price. The consumer is always provided with accompanying certificates. The warranty period for products is seven years. The equipment of the company will not let you down and will serve for many years.

The installation of three-way valves requires special attention. Many nuances should be taken into account. Proper installation of equipment will positively affect the performance of the entire heating system.