According to the main classification, reinforcement is divided into 6 classes: A1, A2, A3, A4, A5, A6, this classification is based on the mechanical properties of the reinforcement, the fundamental of which is strength, the higher the class of the reinforcement, the stronger the product.

The very first class of reinforcement A1 is hot-rolled smooth. The remaining five classes (A2, A3, A4, A5, A6) are hot-rolled bar reinforcement with a periodic profile.

In order to strengthen it, hot-rolled rod reinforcement can be subjected to thermomechanical treatment after rolling. Classes of thermally strengthened reinforcement are divided into classes: At-3, At-4, At-5, At-6, At-7. The mechanical properties of class A rod reinforcement are given in Table. 1.

| Reinforcement classes | Nominal diameter of the rod, not less, mm | Tensile strength, not less, MPa | Yield strength, not less, MP a | Elongation at break, not less, % | Bend angle in cold state with mandrel thickness C |

| A-1 | 6-40 | 380 | 240 | 25 | 180 o , C=0.5d |

| A-2 | 10-80 | 500 | 300 | 19 | 180 o , C=3d |

| A-3 | 6-40 | 600 | 400 | 14 | 90 o , C=5d |

| A-4 | 10-22 | 900 | 600 | 6 | 45 o , C=5d |

| A-5 | 10-22 | 1050 | 800 | 7 | 45 o , C=5d |

| AT-4 | 10-40 | 900 | 600 | 8 | 45 o , C=5d |

| AT-5 | 10-40 | 1000 | 800 | 7 | 45 o , C=5d |

| AT-6 | 10-22 | 1200 | 1000 | 6 | 45 o , C=5d |

| AT-7 | 10-32 | 1400 | 1200 | 5 | 45 o , C=5d |

Notes:

- For thermally strengthened steel At, the conditional yield strength is given.

- The bend angle is a change in the direction of the axis of a certain section of the reinforcing bar relative to the original one. A mandrel is a device around which a sample of reinforcing bar is bent.

- d is the diameter of the test sample.

Reinforcement classes A-2 and A-3, subjected to cold stretch hardening after rolling, have classes A-2b, A-3b. Steel with increased ductility compared to steel A-2 is assigned class Ac-2.

Features of using reinforcement of different classes

Bar reinforcement of class A-1 is used for ordinary (non-prestressed) reinforcement. Basically, reinforcement of this class is used as installation, structural and working (transverse). The weldability of A-1 reinforcing steel is good. Carbon steels VStZps2, VStZsp2 and low-alloy steel 10GT are used for the manufacture of hinges for reinforced concrete products, since they must be made of steel with a high tensile elongation, high impact strength and good cold bending ability. At air temperatures below - 40 o C, reinforcing steel grade VStZps2 is not used for the manufacture of mounting loops.

Rod reinforcement made of steel of class A-2 is used in the same place as reinforcement of class A-1, except for steel grade St5 with a diameter of more than 32 mm, which during welding increases the fragility of the welded joint.

Non-tensioned reinforcement of classes A-1 and A-2 is recommended for welding meshes and frames. Rebar made from class A-3 steel is widely used as working reinforcement in the production of conventional reinforced concrete structures. The weldability of steel is good, except for grade 35GS.

Reinforcement with a diameter of 6-10 mm is used for the production of welded frames and meshes, both flat and rolled. Bar reinforcement made of class A-4 steel is mainly used as prestressing reinforcement, but it can also be used as a regular reinforcement, like class A-3 reinforcement. The weldability of class A-4 steel is considered quite satisfactory, although slightly worse than that of A-3 steel. Therefore, the joining of class A-4 steel rods can be carried out using the so-called “compressed clip” method.

In the designation of classes of thermomechanically and thermally strengthened steels with increased resistance to corrosion cracking, the letter “K” is added, for example At-4K. Weldable steels of the same class have the index “C” (At-5C), and steels that have both the property of weldability and resistance to corrosion cracking - “SK” (At-5CK). According to the recommendations of NIIZHB, for prestressed reinforced concrete structures with a length of 12 m or more, steel of classes At-5, At-6, At-4 (grades 80C), At-4K, At-5CK and At-6K should be used as prestressing reinforcement. Hot-rolled steel of classes A-5, A-6 and A-3c is also allowed for the same purposes and conditions. Moreover, class A-3 reinforcement should be subjected to double control during hardening: elongation and stress.

Hot-rolled steel of classes A-5 and A-6 should be used as prestressing reinforcement in long structures with a span of over 12 m. For rods that are joined along their length by welding (or embedded parts and anchors are welded to them along their length), it is allowed to use steel of classes A-4 grades 20ХГ2Ц, A-5 grades 23Х2Г2Т and A-6 grades 22Х2Г2АУ and 22Х2Г2Р. You can also use reinforcing steel of classes At-4S, grades 25G2S and A-3v.

In prestressed reinforced concrete structures operated in aggressive environments, made from slag pumice concrete or based on slag Portland cement, reinforcing steel resistant to corrosion cracking of classes At-4K, At-5CK and At-6K should be used. It must be remembered that cutting reinforcing steel bars of classes A-3, At-3C, At-4, At-4C, At-4K, A-5, At-5, At-5CK, A-6, At-6 and At -6K should be done cold, that is, on machines using scissors.

Wire reinforcement

Wire reinforcement are divided into round (smooth) ordinary class B-1, periodic profile class Vr-1 (GOST 6727-80) and high-strength class B-2 and periodic profile class Vr-2 (GOST 7348-81), (Tables 2 and 3 ).

Wire of class B-1 with a nominal diameter of 3.0; 4.0; 5.0 mm is used as non-tensioned reinforcement mainly for the production of reinforcing mesh and frames, both welded and knitted, with a height of up to 400 mm. The weldability of the wire is good. Cold-drawn tempered carbon steel round wire of class B-2 and periodic profile of class Br-2 with a nominal diameter of 3.0; 4.0; 5.0; 6.0; 7.0; 8.0 mm is used for reinforcing prestressed reinforced concrete structures. Since reinforcing wire of classes B-2 and VR-2 is subjected to low-temperature tempering, this reinforcing wire is not welded.

| Nominal diameter, mm | Breaking force, N | Breaking force, N | Force corresponding to the conditional yield strength, N | Number of bends per 180 degrees with a roller diameter of 30mm | Relative elongation after rupture, % | |||

| reinforcing wire class B-2 | reinforcing wire class VR-2 | |||||||

| 3,0 | 13 130 | 10510 | 9 | 4 | 12 810 | 8 | 10 250 | 4 |

| 4,0 | 22 150 | 17 720 | 7 | 4 | 21540 | 6 | 17 230 | 4 |

| 5,0 | 32 730 | 26 190 | 5 | 4 | 30 800 | 3 | 24 627 | 4 |

| 6,0 | 44 300 | 35 440 | - | 5 | 41 600 | - | 33 300 | 5 |

| 7,0 | 56 550 | 45 200 | - | 6 | 52 800 | - | 42 300 | 6 |

| 8,0 | 68 890 | 55110 | - | 6 | 64 100 | - | 51 300 | 6 |

Reinforcing steel ropes

Non-unwinding reinforcing steel spiral ropes are used as prestressing reinforcement for the manufacture of prestressed reinforced concrete structures. Ropes can be single-stranded or double-stranded from 7 and 19 wire threads (GOST 13840-68*). The main mechanical properties of reinforcing ropes are given in table. 4. For the manufacture of reinforcing ropes, round steel wire is used (GOST 7372-79*). The wire can be uncoated and galvanized. According to the temporary resistance, the wire is divided into 14 marking groups from 107 to 2352 MPa.

| Nominal rope diameter, mm | Elongation before break, % | Tensile strength, MPa, not less | Conditional fluid limit MPa, not less | ||

| with the state quality mark | 1 category | with the state quality mark | 1 category | ||

| 4,5 | 3 | 19,0 | 19,0 | 16,2 | 15,2 |

| 6,0 | 3 | 18,5 | 18,5 | 15,7 | 14,8 |

| 7,5 | 4 | 18,0 | 18,0 | 15,3 | 14,4 |

| 9,0 | 4 | 18,0 | 17,5 | 15,3 | 14,0 |

| 12,0 | 4 | 17,5 | 17,0 | 14,8 | 13,6 |

| 15,0 | 4 | 17,0 | 16,5 | 14,2 | 13,2 |

Rod reinforcement for reinforced concrete structures is manufactured in the following types: hot-rolled - with a diameter of 6...80 mm; thermally or thermomechanically strengthened - with a diameter of 10...28 mm; reinforced by hood - with a diameter of 20...40 mm.

Hot-rolled rod reinforcement depending on mechanical characteristics are divided into six classes, conventionally designated A-I, A-II, A-III, A-IV, A-V, A-VI. Armature class A-I They produce a smooth profile, the rest of the classes are periodic. Two types of periodic profiles are most often used. In class A-II reinforcing bars, the profile is formed by two diametrically located longitudinal ribs and numerous transverse protrusions running along helical lines with the same approach (Fig. 17, a). In the reinforcement of other classes, the transverse projections are arranged in a herringbone pattern (Fig. 17.6),

Six classes of bar reinforcement are subjected to thermal and thermomechanical hardening; in its designation, hardening is marked with an additional index t: At-III, At-IV, At-V, At-VI, At-VII, At-VIII. The letter C indicates the possibility of joining by rod welding, K - the increased resistance of the reinforcement against corrosion cracking.

Rice. 17. Rebar reinforcing steel of periodic profile:

a - class A-11, b - classes A-III and A-IV; 1 - general view, 2 - unfolded surface of the rods

Rod reinforcement, strengthened by drawing, is produced at enterprises in the construction industry. It is produced in one class - A-IIIc.

The range of reinforcement is compiled according to the nominal diameters of s/n rods. For smooth profile rods (classes A-I), the nominal diameter is equal to the actual diameter. In periodic profile rods dH correspond to the diameters of round smooth rods B with the same cross-sectional area symbol The fittings indicate the profile number, the class of the fittings and the number of the standard regulating its quality. For example, the designation 16At-1US GOST 10884-81* should be deciphered as follows: 16 - nominal diameter of reinforcement, mm, At-1US - thermally strengthened weldable reinforcement.

As the class of reinforcement increases, its strength increases, characterized by yield strength and temporary tensile strength. At the same time, the relative elongation after rupture decreases. The greatest elongation is observed in reinforcement of class A-1 - no less than 25%. Reinforcement of classes A-II and A-III has a significant elongation - no less than 14.19%. Reinforcement of classes A-IV, A-V, A-VI, as well as thermally strengthened reinforcement of all classes, is characterized by a relatively low elongation - about 6...8%.

Each class of reinforcement corresponds to strictly defined steel grades with the same mechanical characteristics, but different chemical compositions.

Reinforcing steel of classes A-1 and A-II with a diameter of up to 12 mm and class A-III with a diameter of up to 10 mm inclusive is supplied in coils or rods, large diameters - only in rods, other classes - also in rods.

Class A-1 reinforcement (GOST 5781-82* and 380-71*) is smooth and has the highest ductility. Therefore, it is used as non-prestressed reinforcement of reinforced concrete structures under pressure from gases, liquids or granular bodies. Class A-1 reinforcement is often used for transverse reinforcement, but it is also allowed for longitudinal reinforcement if other types of non-prestressing reinforcement cannot be used. The reinforcement welds well. From class A-1 reinforcement, made of steel grades VStZsp2 and VStZps2, mounting (lifting) loops for prefabricated concrete and reinforced concrete structures are made.

Class A-1 fittings! (GOST 5781-82*) has higher mechanical properties. Its scope is the same as that of class A-1 fittings. The periodic profile improves the adhesion of the reinforcement to the concrete, and this allows reinforced concrete structures reinforced with class A-II steel to be considered more efficient. Steel welds well. For special purposes, AC-P class fittings are produced. It is manufactured in the form of rods with a diameter of 10...32 mm from 10GT steel alloyed with manganese and titanium. Compared to class A-II reinforcement, it has increased ductility and impact strength at subzero temperatures. Therefore, AC-I class reinforcement is recommended for use in reinforced concrete structures operating at temperatures down to -70°C and subject to dynamic loads.

Armature class A-Sh(GOST 5781-82*) are most often used in the manufacture of structures that are not subject to prestressing. Both working and structural reinforcement are made from it. In addition, transverse rods of welded mesh are made from class A-III reinforcement with a diameter of 6 and 8 mm.

Class A-IV reinforcement (GOST 5781-82*) is produced with the same periodic profile as class A-III reinforcement. To distinguish them, the ends of class A-IV reinforcing bars in the area of 30...40 cm are painted red. Class A-IV rods are used for the manufacture of longitudinal working reinforcement for welded and knitted frames and meshes. They can also be used as prestressing reinforcement for prestressed reinforced concrete elements up to 12 m long, operated under the influence of aggressive environment. Steel 80C, used for the manufacture of reinforcement of class A-IV, is welded satisfactorily, but it is necessary to use special techniques: the rods are joined only by resistance electric welding using sleeves.

Class A-IV rod reinforcement is often used to reinforce prestressed structures made of lightweight concrete of classes B7.5...B12.5 (grades 100...150).

Armature classes A-V and A-VI (GOST 5781-82*) are the most durable, therefore they are mainly used for reinforcing prestressed structures. It is also used in structures subject to dynamic and repetitive loads, for example, in the spans of bridges, overpasses, and crane beams. The use of this reinforcement is limited to the operating temperature of the structures - not lower than -55 ° C. Reinforcement of classes A-V and A-VI is welded with the same restrictions as reinforcement of class A-IV. To increase the reliability of reinforced concrete structures operated at temperatures below -40 °C, reinforcement of classes A-IV, A-V and A-VI is not welded, but is used only in the form of whole rods of measured length.

The profile of reinforcement bars of classes A-V and A-Vi is the same as that of reinforcement of classes A-III and A-IV. When delivering reinforced concrete products to a construction site or plant, the ends of the reinforcement bars class A-V painted red and green color, class A-VI - in red and blue.

Thermally and thermomechanically strengthened reinforcement of classes At-1 II...At-VIII (GOST 10884 - 81*) is used mainly for the manufacture of prestressed structures. Thermal hardening of reinforcement consists of hardening the steel followed by high-temperature tempering. This is how reinforcement of classes At-IV...At-VIII is strengthened. For At-Sh class reinforcement, thermomechanical hardening is used. It consists in the fact that the reinforcing bars are quickly cooled with jets of water after passing through the roll of a rolling mill. This fixes the hardening state, in which the steel acquires increased strength.

At-Sh class steel is made weldable. At the consumer's request, steel of classes At-IV and At-V can be weldable and (or) resistant to corrosion cracking.

At-IIIC class reinforcement with a diameter of 6 and 8 mm is supplied in coils, with a diameter of 10 mm or more - in rods, steel of At-IV...At-VIII classes is supplied only in rods. Reinforcing bars are manufactured in measured lengths of 5.3... 13.5 m. At the request of the consumer, it is possible to supply bars up to 26 m in length.

The ends of the reinforcing bars are painted in the following colors: At-ShS - white and blue, At-IV - green, At-IVC - green and white, At-IVK - green and red, At-V - blue, At-VK - blue and red, At-VCK - blue, white and red, At-VI - yellow", At-VIK - yellow and red, At-VII - black, At-VIII - brown. Non-thermo-treated ends of the rods are painted red.

Rods are supplied packaged in bundles weighing 3...15 tons, and reinforcement with a diameter of less than 10 mm is supplied in coils weighing up to 3 tons.

Draw-strengthened reinforcement of class A-Shv is distinguished by greater strength compared to reinforcement of class A-Sh: its yield strength is 540 MPa. Reinforcement can be used in prestressed reinforced concrete elements, including those under pressure of gases, liquids or granular bodies.

Armature-steel rods, rolled profiles and wires located in concrete to work together with it.

Prefabricated monolithic and monolithic non-tensioned structures are reinforced with enlarged mounting elements in the form of welded meshes, flat and spatial frames, which are manufactured outside the structure being constructed and then installed by assembly cranes. Sometimes complex designs reinforced directly in the design position from individual rods with their connection into a completed reinforcement frame by welding or knitting.

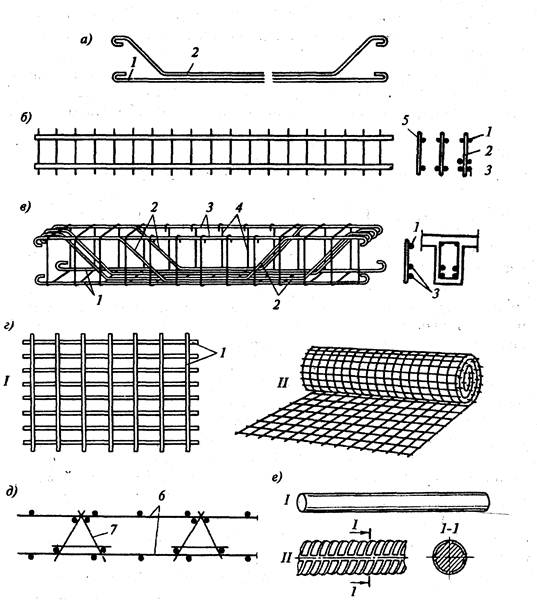

The fittings are divided according to their purpose in the structure into working, distribution and installation (Fig. 8.1).

Working reinforcement absorbs tensile forces arising in reinforced concrete structures from its own mass and external loads.

Distribution fittings serve:

• for uniform distribution of loads between the working rods;

• to provide them collaboration;

• to connect the working rods with each other, preventing the displacement of the working reinforcement during concreting.

Mounting reinforcement usually does not absorb forces, but ensures the exact position of working rods and flat reinforcing meshes and elements in the formwork.

The main reinforcement in modern construction is periodic profile reinforcement, which has reliable anchoring and increased adhesion to concrete. When using rods made of smooth reinforcement, for better fastening in concrete, the ends of the tensile rods are bent in the form of hooks.

In civil engineering, reinforcing bars with a diameter of 12...30 mm are usually used, in industrial engineering - reinforcement with a diameter of up to 40 mm, in hydraulic engineering - rods with a diameter of 90... 120 mm. Rolled profiles are sometimes used as reinforcement.

Reinforcing products include individual rods (bar reinforcement), reinforcing mesh, flat and spatial reinforcement cages, reinforcing products for prestressed structures, embedded parts, mounting loops and clamps.

Bar reinforcement They are made with a smooth profile (due to low efficiency, its output is reduced) and periodic with the projections arranged along a helical line or in a herringbone pattern. The fittings are divided depending on the manufacturing technology into hot-rolled (divided into 5 classes from A-1 to A-VI according to the old designation - according to the new designation A-240 (A-1), A300 (A-III), A400 (A-IV ), A800 (AV), A1000 (AV1)) and hot-rolled with subsequent hardening by stretching in a cold state, it has 2 classes - A-Pv and A-Shv.

Welded reinforcement mesh consist of mutually intersecting rods connected at the intersection points by welding. They are produced with longitudinal, transverse and mutually perpendicular working reinforcement. In general, the meshes combine working and distribution reinforcement and consist of individual wires with a diameter of 3 to 9 mm inclusive and reinforcing steel rods with a diameter of 10 mm, located

Depending on the mechanical characteristics, rod reinforcement is divided into classes:

A-I, A-II, A-III, A-IV, A-V, A-VI. Reinforcing steel bars:

o class A-I- smooth;

o class A-II, A-III, A-IV - periodic profile.

Periodic profile reinforcement is a round profile with two longitudinal ribs and transverse projections. The following is added to the index:

• “t” - for thermally strengthened reinforcing steel,

• "in" - for an ordered hood.

For each class of hot-rolled reinforcing steel, certain steel grades are established (GOST 5781-82)

Class Profile diameter Steel grade

A-I 6-40 St3kp3, st3ps3, st3sp3,

Vst3kp2, Vst3ps2, Vst3sp2

6-18 Vst3Gps2

A-II 10-40 Vst5sp2, Vst5ps2

40-80 18G2S

Ac-II 10-32(36-40) 10GT

A-III 6-40 35GS, 25G2S

6-22 32G2Rps

A-VI 10-18(6-8) 80С

10-32(36-40) 20ХГ2Ц

A-V 10-32(6-8)(36-40) 23Х2Г2Т

A-VI 10-22 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR

Marking: The ends of rods made of low alloy steels must be painted:

o class A-IV - red paint,

o class A-V - red and green,

o class A-VI - red and blue.

It is allowed to paint the ligaments at a distance of 0.5 m from the ends.

Thermo-mechanical and thermally strengthened steel rods of periodic profile with a diameter of 6-40 mm are intended for the construction of critical reinforced concrete structures (GOST 1088-81).

According to this standard, depending on the mechanical properties, fittings are divided into classes: At-III, AT-IV, AT-V, At-VI. At-VII, At-VIII.

Reinforcement according to this standard is made of the following grades of steel:

• At-Sh class from St5 (sp, ps);

• class AT-IV, AT-IVC, AT-IVK from 20GS; 25G2S; 35GS; 28C; 10GS2; 08G2S; 25S2R,

• class AT-V (K and SK) from 20GS; 20GS2; 08G2S; 10GS2; 28C; 25G2S; 35GS; 25С2Р; 20ХГС2,

• class AT-VP from ZOKHS2. In the designation of reinforcement classes, the letters mean the following:

• "K" (AT-IVK) - increased resistance to stress corrosion cracking,

• "C" (AT-IVС) - weldable.

• "SK" (At-IVSK) - weldable and with increased resistance to corrosion cracking.

The ends of the rods of each class must be painted with paint:

• At-ShS - white and blue;

• At-IV - white and yellow:

• At-IVK - green;

• At-V - blue;

• At-VSK - white and green;

• At-VK - yellow and green;

• At-VI - yellow;

• At-V1K - green and black;

• At-VP - black.

Non-heat treated ends should be painted red.

The West Siberian Metallurgical Plant produces thermomechanically strengthened reinforcing steel of classes A400C and A500 according to TU 14-1-5254-94. Low carbon content, along with thermomechanical processing of reinforcing steel in the rolled product stream, ensures its improved weldability and ductility, increased toughness and durability. This reinforcing steel meets the requirements of international standards in its properties.

Construction reinforcement of class A1 is produced at our own metal base by hot rolling and has a smooth profile with a round cross-section. This distinguishes it from class A3 fittings, which have a corrugated profile.

The steel used in the manufacture of A1 reinforcement, in its own way chemical composition strictly complies with GOST 380-88. Other characteristics of the product are subject to GOST 5781-82 standards, which is confirmed by quality certificates.

Range of round reinforcement A1

Our online store offers A1 steel rod reinforcement with the following cross-sectional diameters:Delivery of smooth profile fittings

Smooth A1 reinforcement with a diameter of 6 to 10 mm is delivered in coils or in bars of six meters in length (12-20 mm only for bars 11.7 m long). The rods are collected in bundles before transportation. According to GOST, each bundle is marked and rewound with wire rod in four places for reliable transportation.

The GorSnabStroy group of companies stores A1 fittings in its own warehouses for subsequent prompt delivery to Moscow, the Moscow region and the Russian Federation. We have at our disposal big park trucks. Pickup or transportation of goods by rail is possible.