When constructing pile foundations, a structure such as a grillage is often installed. What this is is known to almost all owners of suburban areas who have ever been involved in the construction of residential or commercial buildings. A grillage is a structural element of the foundation of a house that connects piles buried in the ground and distributes the load from the walls and floor between them.

Varieties

When constructing buildings of various purposes and designs, grillages can be used:

When constructing buildings of various purposes and designs, grillages can be used:

- Metal. This type is mainly used when steel screw piles are used as a load-bearing element of the foundation structure. A metal grillage is most often assembled from a channel or I-beam.

- Wooden. This type is used in the construction of wooden cobblestones, logs or frame-panel buildings. The piles can also be concrete. The installation of grillages is a very simple procedure. In this case, either an ordinary thick beam or a log hewn from below is used as supports for the walls.

- Reinforced concrete. This type is usually used in the construction of brick or block buildings. Structures of this type can be prefabricated (from beams) or monolithic.

Monolithic grillages

This type has the advantage over prefabricated ones that during its installation there is no need to use lifting equipment. It is this type of structure that is most often erected by private owners when building houses on their own. A monolithic grillage, among other things, is very reliable and inexpensive.

Methods for pairing the tape with piles

Sometimes the grillage is placed on pillars without any bond. This method can only be used when there is no further horizontal dynamic impact on the foundation. For centrally loaded piles, free coupling is sometimes used. In this case, their top is simply embedded in the body of the grillage tape to a depth of approximately 10 cm.

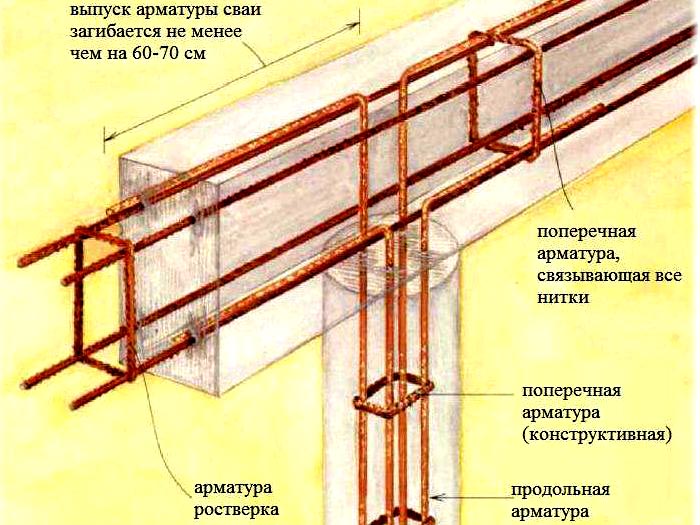

In the construction of residential buildings, the so-called “rigid” connection is often used. In this case, reinforcement (about 30-40 rod diameters long) is released from each pile, which is subsequently connected to the grillage frame. This connection ensures maximum reliability of the structure. The result is a very strong and durable pile foundation with a grillage.

Pouring pillars

When constructing a foundation of this type, piles are buried in the soil to its dense stable layers and below the freezing level of the soil. The distance between them is usually about 1-1.5 meters. A hole is drilled under each pile, the walls of which are lined with roofing felt, which, among other things, also serves as formwork. In each such hole in the ground, 4 rods with a cross section of usually 12 mm are inserted, connected with clamps for stability.

Grillage calculation

The easiest way to find out the required section of the tape is to use some computer program designed for this purpose. For example, GIPRO or “Grillage Designer”. For the calculation, you will need to enter data such as soil type, building weight, concrete grade, etc.

Grillage installation: preparatory work

After installing the pillars, no earlier than the concrete has gained half its strength (a week), they begin to pour the tape itself. Above the ground, the monolithic grillage should be located at a height of no less than 5 cm, and on swampy or heaving soils - 15 cm. This is necessary in order to avoid the pressure of the earth on it during spring heaving, and, consequently, the tearing of the tape from the heads of the pillars.

The bottom of the formwork for a grillage located very high above the ground is made of boards. In this case, a wooden “box” is arranged in a shape that repeats the configuration of the tape itself. The width of the grillage is usually made equal to the thickness of the walls.

If the tape is not located too high above the ground, the formwork is made without a bottom. To hold the liquid concrete inside it, a sand bedding is made from below. You can also use thick polystyrene foam or plywood mounted on bars as the “bottom”. Before installing the tape, the upper plane of the piles must be waterproofed with two layers of roofing material.

Filling the tape

So, how is the grillage itself constructed? We found out what this is above. In essence, a grillage is an ordinary concrete strip reinforced with a metal rod. This structure encircles the perimeter of the house. There is a grillage and under the walls inside it. It is poured in much the same way as a regular strip foundation. The only thing is that in this case there is no need to perform labor-intensive excavation work, as well as install a sand cushion.

After assembling the formwork, wooden blocks approximately 5 cm thick are installed at its bottom. A connected reinforcement frame is placed on them. The latter is made from 12 mm rod. Only the longitudinal elements that bear the load should have such a cross-section in the frame. The transverse ones simply serve to connect the structure, so they can be thinner (about half).

Frame standards

When constructing a structure such as a grillage on piles, it is allowed to use only reinforcement manufactured in compliance with certain rules prescribed by SNiP. To strengthen the tape, you can only use a frame with at least two tiers. Moreover, each of them must have at least two longitudinal rods.

The pillar reinforcement is pre-bent and connected to the grillage frame using knitting wire. The use of welding when assembling a reinforcing metal structure, both for the tape and for the piles, is not allowed. The fact is that places connected in this way begin to rust very quickly, and this in turn leads to a decrease in the service life of the foundation.

It is advisable to lay concrete into the tape in one step. In this case, you will get the strongest and most durable pile foundation with a grillage. During pouring, the mixture should be periodically pierced with a wooden stake or rod to remove bubbles. The edges of the formwork are pre-wetted with water. The sand backfill, polystyrene foam or plywood from under the tape can be removed after a week.

Pickup device

In order for the floors in a house resting on a grillage on stilts to be warm, the space between the tape and the ground is usually covered with boards or some sheet material. This could be, for example, plywood, basement siding, etc. At the same time, timber is laid around the perimeter of the house. It is necessary for attaching the casing from below. From above it is fixed directly to the base itself. The fence is not connected to the poles. Otherwise, it may crack during heaving.

Advantages and disadvantages

This is how a structure such as a grillage is constructed. What it is, you now know. Next, let's look at the advantages of a pile-grillage foundation for a house.

The advantages of foundations of this type include, first of all:

- Low cost. These get by support structures cheaper than even the currently most popular shallow-depth tape ones.

- Reliability. On problematic soils, a pile grillage ensures the longest service life of the building. It is practically not affected by the forces of spring heaving, as well as melt and rain water. The owners of the house have the opportunity to control the condition of the tape over the entire area, since it is not buried in the ground.

- Easy to install.

The disadvantage of this type of foundation is mainly considered to be the impossibility of installing it when using a basement or ground floor. The disadvantages include the not very high tensile strength of the concrete tape. It is impossible to erect a pile-grillage foundation on soils subject to movement.

Thus, you now know how the grillage is arranged. What it is, as well as what advantages and disadvantages such a design has, we found out in detail. Columnar foundations with a grillage are very reliable foundations, simple to construct and at the same time inexpensive.

Grillage - what is it? Monolithic grillage

To connect the pillars and distribute the load from the walls, a special design is used - a grillage. What this is is known to most owners of suburban areas who have ever been involved in the construction of residential buildings or outbuildings. Most often, a monolithic reinforced concrete grillage is installed under low-rise buildings.

The design of a pile foundation can be selected depending on the mass of the entire building and the materials used in construction and types of piles. It can be wooden, metal or concrete. Concrete can be monolithic or consist of concrete beams or panels. The connection between the strip part and the pile head has many design options. Depending on the needs and financial capabilities, a wide variety of pile foundation designs are used. But there are types of soil, for example swampy, on which it is possible to use only piles.

Most often, a foundation with bored supports and a monolithic concrete grillage is used. Other options for pile foundations cause various complications in operation. Wooden beams are relatively short-lived and their load-bearing capacity is significantly limited. Wood is susceptible to fungi and rot. Metal structures are subject to corrosion, and their installation requires the use of lifting equipment. When installing a concrete block foundation, it needs lifting crane. With a monolith of a bored pile foundation, the immobility of the connection between the grillage and the pile heads is ensured, which ensures high structural rigidity and the required stability of the entire pile foundation. When erecting a monolithic structure, you can do without lifting mechanisms.

Return to contents

Design features of a monolithic grillage

Installation of a grillage in a monolithic foundation.

To ensure high strength, the structure of a bored foundation does not allow communication channels to be laid in its body. Reinforcement is performed in at least two tiers. Each tier must contain at least two rods. The grillage experiences a load from above from the weight of the entire building, and on heaving soils in winter, loads from soil movement from below are added. For longitudinal bars of a pile foundation, reinforcement with a variable cross-section with a diameter of up to 12 mm is used. Transverse rods do not carry loads and serve only for the construction of the reinforcement frame. Their diameter can be half that size. The reinforcement frame must be recessed into the concrete to prevent contact with environment and to protect the rods from corrosion.

The technology for constructing bored foundations with a grillage requires paying special attention to the connection of the pile reinforcement with long rods in the tape frame. When preparing the head, the pile rods should protrude from the top. To create a good connection, these rods are bent and tied with tying wire to the grillage rods. To fill the monolithic reinforced concrete grillage of the pile foundation, wooden formwork is installed.

Depending on how the foundation body is located relative to the soil level, there are different design features. On swampy and other heaving soils, the body of the foundation is raised above the soil surface to a level of up to 150 mm. Such a high grillage is made in order to prevent the influence of forces from the ground when the soil swells in winter. As a result of soil swelling, the grillage may be torn off from the pile heads or pulled out of the soil. But this arrangement of the grillage has a major drawback. After construction is completed, a void remains between the floor of the house and the ground, which requires additional insulation of the floor below. The design of such a house does not have a basement.

A design in which the lower part of the tape is at the level of the ground surface or buried below this level avoids voids under the floor. But this option requires providing an air gap directly under the grillage. The recess is made to the same 150 mm.

To prevent the resulting space from being filled with collapsing soil, barrier plates made of slate or sheet metal are installed.

A fence is used to cover the space under the foundation. When installing a pick-up, the recess is filled with a material that is not subject to swelling and has looseness. Both recessing and additional fencing require additional costs, so a raised foundation has clear advantages in this regard.

Foundations are used for the construction of residential and industrial buildings various types, but the pile-grillage structure deserves special attention. It is usually chosen in cases where the land plot has sharp changes in relief, heaving and weak soil. This type of foundation is also well suited for development in areas located in the permafrost zone.

Specifications

A pile-grillage foundation is a reinforced concrete, wooden or steel foundation filled with concrete, in which all elements are connected into a single structure. Its structure can be either monolithic (covered with a slab) or built using a hanging grillage. A hanging foundation is characterized by an open gap between the soil surface and the grillage; it must be additionally insulated and covered with waterproofing. As for the monolithic version, it is formed from a concrete frame in which the height of the platforms is leveled with piles of different lengths.

Since when laying the foundation, piles are used, buried in the ground between the load-bearing layer and the lower freezing level, it is difficult to distribute the load of the building between them. Therefore, the pile-grillage foundation is often made from a prefabricated channel and timber. All supports of this design are attached to the unit using special tapes and concrete. It is worth noting that the combination of grillage and piles gives the load-bearing foundation reliability and stability.

Depending on what kind of foundation is laid (wooden, metal, concrete or reinforced concrete), the foundation for construction acquires different technical characteristics. According to the requirements of SNiP, the construction of structures with low and high grillages, which are located above ground level, is allowed. They are usually made from metal pipes large section or made of concrete. At the same time, making grillages from concrete is much more difficult, since it is necessary to accurately calculate the location of the tape from the soil.

The main feature of the foundation is that the grillages included in its structure perfectly withstand uneven loads, providing the foundation with a rigid interface. The grillages redistribute the load, as a result of which the already “leveled” weight of the building is transferred to the piles, and the building is protected from the formation of cracks in the walls.

Purpose

Unlike other types of foundations, a pile-grillage foundation ideally distributes the load-bearing loads from buildings onto the ground, so when choosing it, you can be sure that the new building will reliably serve for decades and will be protected not only from sudden temperature changes, but also from seismic activity. Such structures are widely used for both public and individual construction. They are especially suitable for areas located on a slope with heaving, permafrost soil and difficult terrain.

- for building a brick house;

- in frame construction;

- for structures made of gas silicate blocks;

- on soils with high density;

- with high groundwater distribution;

- on unstable soil with quicksand.

The pile-grillage design also makes it possible to lay floors directly on the ground without additional leveling of the surface and pouring a deep tape, since piles installed at different heights compensate for all unevenness, eliminating height differences. Such a foundation can also be used in the construction of buildings weighing more than 350 tons - it will be much more reliable and economical than a strip or tile foundation. But in this case, the project will have to include an increased safety factor, which should be not 1.2, as usual, but 1.4.

Advantages and disadvantages

The pile-grillage foundation is a single system consisting of a grillage and supports.

Due to the presence of a concrete base in the structure, reinforced with reinforced elements, the base acts as a reliable support for buildings and is characterized by some advantages.

- High economic benefit. Installation does not require large financial costs, since earthworks are kept to a minimum.

- Sustainability. The large load-bearing capacity makes it possible to erect multi-storey buildings using heavy building materials in their finishing.

- Expanded construction coverage. Compared to other types of foundations, territory development can be done on any type of soil that is not suitable for laying traditional foundations. Difficult landscape geometry, slopes and slopes are not an obstacle to work.

- Possibility of forming cast-in-place piles separately from the grillage. Thanks to this nuance, the concrete mixture is significantly saved. In addition, you can use both ready-made and self-prepared solutions.

- Convenient location of piles with cable lines and underground pipelines. This simplifies project creation and does not break the functionality of the settings.

- High strength. The monolithic combination of grillage and supports protects the structure from soil shrinkage, so the structure does not break or deform during operation.

- Lack of preparatory work. To lay a pile-grillage foundation, there is no need to form a foundation pit, which simplifies the construction process.

- Good thermal insulation. Thanks to the increased arrangement of the grillage, the space between the ground and the base does not allow cold air flows to pass through - this reduces heat losses and makes the building warm.

- No risk of flooding. Pile structures, raised up to two meters above the ground, protect the structure from possible flooding.

- Easy to install. Having minimal construction skills, it is quite possible to build such a foundation with your own hands, without resorting to the help of craftsmen or using earth-moving devices.

- Short terms of work.

The above advantages are only relevant if the installation of the foundation is carried out in compliance with all construction technologies, and the building is operated in accordance with the loads calculated for it.

In addition to the advantages, this type of foundation also has disadvantages:

- Impossibility of construction on rocky soil - hard mineral rocks make installation of piles impossible.

- Problematic installation in areas with horizontal displacement. It is not recommended to carry out work on soils that can sag, otherwise the stability of the supports will be disrupted and the soil will fail.

- For buildings whose construction is planned in harsh climatic regions with low temperatures, additional measures will have to be taken to install high-quality thermal insulation.

- Such grounds are not provided for the implementation of projects of houses with a basement and ground floor.

- Difficulty in calculating the bearing capacity of supports. It is difficult to calculate this indicator on your own. In case of the slightest inaccuracies, the foundation may become distorted, and as a result, the geometry of the entire structure will change.

Despite the shortcomings, the pile-grillage foundation has proven itself well among builders and has received only positive reviews from home owners.

Kinds

The supports that are used in the construction of a pile-grillage foundation are selected in accordance with the load of the building, the type of soil and climatic conditions. They can be made from metal, concrete, wood, or combined materials.

Therefore, depending on the characteristics of the piles and the method of their installation, several types of foundations are distinguished.

- Screw. It is made from hollow metal pipes with an open end. The work is performed manually or using special equipment. In order for the structure on screw supports to be strong and the pipes to be protected from oxidation, their hollow part is filled with a solution.

- Bored. It is formed on a land plot by pouring concrete into a previously prepared reinforced well located on driven piles. The rammed foundation has high strength.

- Reinforced concrete. Installation is carried out using ready-made reinforced concrete supports installed in the well.

- Driven. As a rule, such foundations are chosen for the construction of large objects. The supports are driven in using special equipment, after which the concrete solution is poured.

In addition, the foundation may differ in the depth of the grillage and can be:

- buried;

- ground;

- raised above the ground to a height of 30 to 40 cm.

A recessed grillage is usually used when installing piles intended for heavy buildings made of aerated concrete or brick. In this case, the slab is additionally tied, and the foundation can serve as the basement of the building. As for the construction of wooden structures, a foundation with a raised grillage is ideal for them - this allows you to save money on building materials, and the raised building will protect against soil heaving.

Design and calculation

An important point Before laying the foundation, its exact calculation is considered. For this purpose, a project and plan for the future building is created. Then a drawing of the foundation is drawn, and the layout of the piles must be indicated, taking into account their location at the intersections with the walls and in the corners. It is necessary to ensure that the width between the piles is at least 3 m. If the distance to their edge is more than three meters, then the installation of additional supports will be required. In addition, the area of the piles should be calculated - for this, their number is first determined, the minimum height and thickness are selected.

For correct calculations, you also need to know some other indicators:

- the mass of the future building - it is necessary to calculate not only all the finishing materials, but also the approximate weight of the internal “filling”;

- supporting area - using the known weight of the structure and the reliability coefficient, the load on the supports can be easily determined;

- dimensions and cross-sectional area of the piles - thanks to the known number of supports, their number can be multiplied by the selected area and get the desired value.

All results must be compared with the previously determined reference area. In some cases, it is necessary to reduce or increase the area of the supports, since their bearing capacity will depend on the diameter and type of soil.

Construction stages

The foundation on piles and grillage is complex design, but it’s quite possible to make it yourself. In order for such a base to serve reliably, special TISE technology must be used during work and step-by-step instruction installations.

The construction of a pile-grillage foundation involves the following work:

- foundation calculation and project creation;

- preparation and marking of the construction site;

- drilling wells and digging trenches;

- formwork formation;

- reinforcement;

- pouring concrete mortar and hard sealing of joints.

Each of the above points is important, therefore, at each stage of construction, quality control should be checked, since the slightest error or inaccuracy will then negatively affect the operation of the building.

Marking

Before starting construction, carefully prepare workplace. To do this, first of all, the area is cleared of mechanical obstacles in the form of stones, roots and trees. Then the ground is well leveled and the fertile layer is removed. After this, markings are applied indicating the location of the piles. The work is done using a cord and wooden stakes.

The markings must be installed strictly along the diagonals. The cords are stretched to mark the inner and outer surfaces of the walls. If inaccuracy is made, deviations from the design will result, and the foundation may become distorted during operation.

In the case where there are small differences in elevation in the area, marking is easy to do. For areas with difficult terrain, the help of experienced craftsmen will be required. Particular attention should also be paid to the corners of the building - they should form an angle of 90 degrees.

Digging a trench

Once the boundaries of the foundation have been determined, excavation work can begin. First, a trench is dug under the grillage, then holes are drilled into which the piles will later be installed. Work is usually carried out using hand tools such as a crowbar, shovel and drill. If financial capabilities allow, you can order specialized equipment.

Depending on the purpose of the future building and the type of soil, the optimal width of the grillage is chosen. For commercial objects, the acceptable figure is 0.25 m, for moving ones - 0.5 m, and for residential buildings this figure increases to 0.8 m. As for the depth, the grillage can be 0.7 m deep.

In a dug ditch, you need to check the bottom and walls for evenness - a laser level will help with this. After this, a sand cushion is placed at the bottom of the trench, and the sand is selected in a coarse fraction. After laying it, the surface is moistened with water and compacted thoroughly. The sand cushion cannot be less than 0.2 m. The next stage of excavation work will be the preparation of holes for vertical piles: holes are drilled to a depth of 0.2-0.3 m.

Then pipes are installed in the finished pits, which will act as formwork, and the bottom is covered with waterproofing material - this will protect the structure from moisture.

Grillage installation

An important point in construction is the installation of the grillage. Most often, a metal element is chosen for work, which is easily welded to the pile heads. In order for the structure to evenly transfer loads, it must be placed strictly horizontally. If the construction of the foundation according to the project involves the use of a low reinforced concrete grillage, then additional backfilling is made of medium-fraction crushed stone. Crushed stone is poured in several layers of 5 cm and compacted well.

Formwork is placed on the prepared base. The width of its tape must exceed the width of the walls, and the height is calculated in accordance with the indicators of the base. Installation of stops and assembly of panels is in many ways similar to the technology for strip foundations.

As for reinforcement, in most cases, similar to the construction of a tape, two belts of ribbed reinforcement are made from below and above. They are tied together with piles. The ends of the reinforcement coming out of the piles are bent: one row is tied to the upper chord, and the other to the lower one.

Reinforcement outlets should not be less than 50 mm from the diameters of the rods. For example, if you use reinforcement with a cross-section of 12 mm, then it is recommended to bend it by 60 mm.

Laying embedded parts

After all work on the manufacture of the frame is completed, it is necessary to consider the placement of communication systems. To do this, boxes and pipes are laid through which sewerage, electricity, water supply and heating will pass. We must also not forget about laying pipes under engineering systems and products. If this stage is not completed, then after construction, concrete will have to be chiselled for installation work, which may compromise its integrity and damage the building.

Pouring the solution

The final step in installing the foundation is pouring the concrete solution. For concreting, M300 grade cement, crushed stone and sand are usually used. The mixture is prepared in a ratio of 1: 5: 3. In this case, the solution is not simply poured in - it is also additionally vibrated. Thanks to this, the surface is durable and uniform.

First of all, the holes intended for the piles are filled with concrete, and then the formwork itself. It is advisable to complete the work process in one go. If you concrete in stages, then unevenness and air bubbles may appear. The optimal temperature for pouring is considered to be +20C - at this level the formwork can be removed after four days. During this period of time, the concrete will gain strength and become ready for subsequent construction work.

Sometimes the foundation is laid at temperatures below +10C - in this case you will have to wait at least 2 weeks for complete drying. In winter, the poured concrete will need to be additionally heated and insulated.

The pile-grillage foundation must be erected correctly, adhering to all construction technologies - this will help increase its technical and operational characteristics.

If construction work is carried out by novice craftsmen, then they need to take into account some recommendations from experienced specialists.

- The installation should begin with calculations. To do this, the type of soil and the depth of the grillage are determined. If the depth of the support is insufficient, the building may shrink and crack, and then even collapse.

- A huge role is played by soil testing, on which the bearing capacity of the structure depends. Rocks and rocky soils have the highest rates. If the composition of the soil is incorrectly determined, this will lead to errors in calculating the load of the structure, as a result of which it will sink into the ground.

- There must be a good connection between the piles and the grillage, since under the influence of soil pressure the unstable structure can collapse.

- Regardless of the type of foundation, a sand cushion must be laid to the freezing depth - this is especially true for the operation of the foundation in winter. Frozen soil can expand and cause grillage ruptures.

- The grillage should not be in contact with the surface of the ground or be buried in it. It is necessary to remove a small layer of soil along the entire perimeter of the site, then install the formwork, fill it with sand and pour concrete.

- The step between piles must be accurately calculated. This indicator is determined in accordance with the load on the foundation, the diameter and amount of reinforcement.

- During reinforcement, it is worth providing the required number of ventilation ducts. All internal compartments must be connected to exits to the street.

- Insulation and waterproofing play a huge role in the construction of the base. They should be laid before the foundation is poured with concrete.

- The bottom of the pit or trench must be compacted and not loosened. Do not allow soil from the walls to fall onto the base. In addition, sedimentary water must drain away from the trench or pit, otherwise the bottom will become wet and will be unsuitable for filling with mortar. Excessive steepness of slopes in trenches is also unacceptable.

- Weak soil requires reinforcement with piles and good backfill.

- The sand that is used to backfill the air cushion must be moistened and the cushion must be distributed under the contour, cut off at an angle of 45 degrees.

- The formwork must be securely fastened, since when poured with concrete it may not withstand the load and collapse. Deviation of the formwork from the vertical by more than 5 mm is not allowed.

- The height of the foundation is made with a small margin of 5-7 cm from the height specified in the project.

- When reinforcing the frame, it is recommended to use rods with a total cross-sectional area of at least 0.1% of the area of the concrete element. In this case, it is best to choose smooth reinforcement, free of traces of rust, dirt and paint.

We will send the material to you by e-mail

Before building a house and deciding which foundation to create - or a pile foundation, novice builders are faced with such a concept as a grillage. Below we will look at what a grillage is and its necessity when constructing the foundations of a building.

General view of the monolithic structure

A grillage is a horizontally located element of the pile foundation of a structure (a kind of belt or cushion), which takes on the entire load of the building and, evenly distributing it, transfers it to the support columns. This is achieved by tying the piles into a complete structure. Since a grillage on a pile foundation increases the strength of the building, it is necessary to ensure sufficient rigidity for all connection points.

The advantage of such a foundation for a building is its durability, strength and the ability to build on sandy and clay soils, as well as on quicksand. In addition, due to the insignificant amount of preparatory work and the concrete mortar used, such a house foundation design is considered a less expensive option compared to other types of foundations.

To better understand what a grillage is, you need to know its classification into the following types:

- at the place of arrangement;

- on the building materials used;

- by constructive solution.

By location:

- Shallow. This is the optimal type of construction to obtain reliable stability. Since the base of the belt is located directly on the ground, the entire future load from the structure will be distributed not only between the piles, but also over the entire foundation.

- Recessed. In this case, part of the structure with a sole width of 50 cm or more enters the ground. These are used for the construction of multi-story buildings on unstable soils.

Video: grillage device for a wooden house

Metal belt for foundation

Metal sheathing is made of channel, I-beam or square profile and has high strength and rigidity. As a rule, this design is used when constructing pile-screw foundations for. The channel is installed on the heads of the supports and fixed by means of a welding connection.

A metal belt is used mainly in a hanging version. However, in Lately such structures are used very rarely, since due to the heaviness of the material, the use of special lifting equipment is required, which is not economically profitable. In addition, the metal is at risk of corrosion processes.

Types and purpose of grillages

Grillage structures vary in type and purpose. When choosing the required design, many factors are taken into account.

Strip foundations with grillages

For buildings, a fairly strong and reliable support is pile foundations with a strip grillage, for the construction of which two technologies are used. One of them is used when arranging foundations above ground level, and the second is used at the stage of creating a lattice structure that takes on part of the load.

A strip foundation is the best option for constructing a foundation on slopes and areas with complex terrain, since it does not require complex preparatory work to plan the site using special equipment. This design is perfect for the construction of structures made of lightweight materials.

Using a strip foundation when building a house requires the following:

- Sand cushion, the thickness of which is 200-300 mm. It is created under a concrete frame and piles to protect them from the destructive effects of ground moisture.

- Waterproofing gratings and supports, for which polyethylene film, roofing felt or asbestos-cement pipes are used.

When arranging the foundation, it is necessary to carefully consider the strip grillage, as well as its thickness and other parameters.

For the fence

The installation of a grillage for fences is necessary for complete protection of the structure, which the plane of the fence cannot provide. The creation of the belt is due not only to provide protection from external factors, but also to ensure that, for example, pets cannot get out of the area. The reasons may be any, but the execution must always be of high quality, ensuring the strength and durability of the structure.

In principle, a grillage for a fence is practically no different from the belt used in arranging the foundations of houses. The same design and building materials are used here and similar functions are performed.

For pile foundation

Necessity of the device columnar foundation with a grillage is determined directly by the specific design of the building, its weight and the rigidity of the structure’s frame. To prevent the support columns from collapsing, they are bound with a monolithic reinforced concrete, metal or even wooden belt.

Several schemes for pile foundations of buildings are used in construction:

- Columns with a hanging belt are buried in the ground. This scheme used in 90% of all pile foundations;

- The pillars rest on a crushed stone embankment without going deep into the ground. With this scheme, high rigidity of the base of the house is ensured, which makes it possible to minimize the likelihood of subsidence of the structure;

- No grillage. This option is used for the construction of small houses.

On a note! Supports for the columnar base of a building can be combined, for example, brickwork is combined with pouring concrete mortar or a base made of rubble. In principle, this does not change the properties of the foundation, but the arrangement process is greatly simplified and the cost is reduced.

Pile-grillage foundations

Grillage technology with bored piles

Arrangement of foundations with a grillage on bored piles is mandatory when constructing buildings on uneven terrain, slopes and unstable soils. These structures are the best option for the construction of both small houses and medium-sized permanent structures. Bored foundations with a grillage have a higher load-bearing capacity than monolithic and strip foundations, and they are cheaper.

Bored piles are able to withstand a load of about 1500 kg. To erect a medium-sized structure, you will need several dozen columns, the diameter of which can reach up to 150 cm and the length up to 40 m.

To arrange the base of the building, no major excavation work is required. Each pile is waterproofed with two layers of roofing felt or roofing felt and fixed in a non-freezing layer of soil. Waterproofing helps protect concrete from destruction and reduce soil pressure on supports.

Advantages of a foundation on bored supports:

The tops of the installed pillars are cut off at the same level, after which they are united by a common belt. A grillage on bored piles allows for uniform distribution of the load exerted by the weight of the structure throughout the entire base of the building. The construction of a pile-grillage foundation can be seen in the video below:

The disadvantage of this design is the fact that due to the presence of free space between the floor and the ground, a bored foundation with a grillage needs to be insulated. This leads to additional labor and material costs.

Grillage on screw piles

The advantage of foundations on screw piles is that their installation does not require excavation work, and they are usually used on clayey and heaving soils. After the supports are installed, their heads are cut to one level and a lattice belt is installed.

Monolithic reinforced concrete and concrete structures for screw piles are made extremely rarely, since this type of support is used for the construction of lightweight structures. Most often, a pile-screw grillage is made from a metal corner or channel.

Before installing the grillage on the heads, metal platforms are welded to them, the size of which should allow the axial displacement of the supports to be corrected. Next, all the piles are tied with a channel or angle, resulting in a strong and reliable structure.

Important! Before installing the foundation and grillage on screw piles, it is necessary to carry out anti-corrosion treatment of all metal structural elements. This will significantly increase the service life of the structure being built.

Main dimensions and dimensions

To create a strong and durable foundation, it is necessary to make the correct calculations. The shape and dimensions of the grillage used are determined by the design features of the building being constructed, the loads on the foundation, and the number and location of piles.

The grillage is created in the same way as the strip foundation structure. The height of the grillages for pile foundations directly depends on the level to which the structure should be raised from the ground, as well as on its weight. You can independently calculate a structure resting on the ground or slightly recessed. In the case of constructing a hanging belt, it is better to entrust the calculations to specialists, since they are very complex for a non-professional.

- B – minimum permissible height for belt support;

- M – weight of the structure of the structure without taking into account the supports used;

- L – belt length;

- R – soil strength at the surface of the earth.

Reinforcement frames for belts on a pile foundation are created in the same way as for construction on a strip foundation. The structure requires longitudinal (working), horizontal and vertical transverse reinforcement. The total cross-section of the longitudinal reinforcement must be at least 0.1% of the cross-section of the belt. To select the cross-section of each rod and their even number, an assortment of reinforcement is used.

Main manufacturers and standard series of pile grillages

For private or small buildings, you can make lattice belts yourself directly on the construction site, but when constructing industrial buildings, multi-storey buildings and so on. use factory-produced designs. Among the main manufacturers of precast concrete grillages from 35 tons, the following companies can be distinguished:

- JSC APSC "Gulkevichsky" ;

- CJSC "OBD" ;

- JSC "T-Beton" ;

- LLC "LSR. Construction-Ural" ;

- LLC "ZKPD Tomsk House-Building Company" ;

- JSC "PZSP" .

| Series | Description | |

|---|---|---|

| Monolithic reinforced concrete grillages Series 1.411.1-1/89 | For the installation of foundations for prefabricated reinforced concrete columns of single- and multi-story industrial buildings of the II 20-1/70, II 20-2/70, II 20-3/70 series. | Structure supports of the II 20-1/70, II 20-2/70, II 20-3/70 series have a cross-section of 400*400 and 400*600 mm. and must be embedded into the foundation at 600 mm. |

| Series 1.011-6 | Made from heavy concrete class B 12.5 | Square piles 300*300 and 350*350 mm. |

| Series for metal grillage: 3.407.9-1581 | To operate the structure at temperatures: ● up to - 40˚C the grillage is made of carbon steel grade VSt 3, corresponding to GOST 380-71; ● below - 40˚C for the grillage, low-alloy steel grade 09G2S is used, which corresponds to GOST 19281-73 and 19282-73. |

|

The name used to designate typical grillages for pile foundations includes the mandatory letter indices RS and RB and serial numbers. Markings RS1 – RS5 are used on square supports, and RB – for rectangular piles.

Important! If it is necessary to order grillages from 50 tons, the concrete manufacturer must be chosen especially carefully to ensure the strength and durability of the entire structure.

Basic provisions for the design and calculation of a pile grillage

When installing a pile-grillage foundation, it is necessary to know the basic requirements for the grillage and carry out competent calculations of the entire structure. It is also necessary to have an as-built diagram for the grillages, which indicates all the main structural elements. An important point when designing the foundation of a building is the accurate calculation of the required number of supports for each specific type of structure. The calculations are based on the total weight of the structure and the bearing capacity of the soil. The mass of the house must be divided by the bearing capacity of the soil and we obtain the area of the designed foundation. To determine the safety factor, the foundation area should be increased by 30%. To calculate the required number of support columns, the area of the base must be divided by the volume of each pile, and the following conditions must be met:

- supports must be installed in all corners of the structure being constructed;

- piles are mounted at the intersection points of the building walls;

- According to SNIP, the distance between the piles in the grillage is 2-2.5 m.

The connection between the pile and the belt can be rigid or free. In the case of a loose connection, the heads of the supports enter the grillage to a depth of 50-100 mm. This type of fastening is suitable for centrally loaded support columns.

With a rigid connection, the pile head is broken and the reinforcement is exposed, after which it is embedded into a concrete or reinforced concrete grillage. This type of fastening is performed in cases where:

- the installation of pile foundations with grillages is carried out on unstable soils;

- horizontal loads are placed on the supports;

- combined or inclined supports are installed at the base;

- support columns work with pull-out loads.

Calculation example

Let's consider an example of calculating a pile foundation with grillages for a one-story brick house with a hip roof made of metal tiles. The building has two reinforced concrete floors with a thickness of 220 mm. Dimensions of the house in plan – 6*9 m, thickness load-bearing walls is 380 mm. The total height of the floor is 3.15 m, from floor to ceiling – 2.8 m, and the total length of the partitions inside the building is 10 m (there are no internal walls in the rooms). The site contains a refractory mixture with a porosity of 0.5 and a depth of 3.1 m.

We pre-set the grillage width to 400 mm. and height 500 mm. The length of the support is 3 m, and the cross-section is 50 cm. We focus on the pitch of the support piles – 1.5 m. To determine the total number of piles, it is necessary to divide the length of the grillage by the pitch of the supports and add 1 (if necessary, round the resulting value down to the nearest whole number numbers – 30/1.5+1≈21).

- Support area, m 2 3,14*0,52/4 = 0,196

- Perimeter, m - 2*3,14*0,5 = 3,14

- Grillage weight, kg- 0.4 m.*0.5 m.*30 m.*2500kg/m 3 = 19500

- Weight of supports, kg- 21 * 3 m * 0.196 m 2 * 2500 kg/m 3 * 1.3 = 40131

- Weight of the building, t- Weight of supports + weight of grillage + sum from the table ≈ 224

To calculate the volume of the grillage and other parameters, it is necessary to determine the mass of the structure without foundation supports. As a result, we obtain M = 204 tons. The width of the salting is equal to M / (L * R) = 204/ (30*75) = 0.09 m. Such a belt cannot be used for construction, in this case, since the overhangs of brick walls should not be more than 40 mm. Therefore, we set the width to 400 mm, but the height remains 500 mm.

Article

To save construction time, budget and at the same time give durability to the building, a variety of construction technologies are used. This applies to all elements of the building, from the foundation to the roof. Let's consider what a pile made using a monolithic grillage is. This type of foundation is used for the construction of low-rise buildings. A monolithic pile foundation is not as strong as other types, but this is compensated by the complete absence of excavation work. And one more advantage - you can start building it even in winter.

A pile foundation with a monolithic grillage is used mainly on soft soils or with a high freezing depth.

You can build a pile monolithic foundation using the following steps:

- Survey and earthworks.

- Installation of supporting elements (piles).

- Installation of grillage.

- Construction of the basement.

Materials used in the construction of a pile foundation:

Diagram of a pile-grillage foundation: 1 – bored pile made of monolithic concrete and frame made of reinforcement; 2-grillage made of monolithic concrete and frame made of reinforcement;3 – horizontal waterproofing; 4 – vent.

- roofing felt;

- reinforced frame;

- concrete.

A monolithic pile foundation is made from various materials. Piles are made from concrete mixture. The structural system itself is made from prefabricated or monolithic reinforced concrete, as well as steel and wood.

In general, the entire process consists of the same stages as in the construction of any other foundation, but still, at each stage you can encounter its own unique installation operations, characteristic specifically for a pile foundation.

Excavation

Using a hand drill, you can drill holes for piles up to 5 m deep and no more than 30 cm in diameter.

During excavation work, an earth drill is used to construct a pile foundation. It is a device of two rods with a loosening and cutting cup. The drill makes small holes under the piles. You can use a hand drill, which drills holes up to 5 m. It is used when the diameter of the foundation support is no more than 30 cm. A motorized drill is used when it is necessary to drill a hole of a large diameter (from 50 cm). That is, when constructing a small pile foundation with a grillage, you can use manual labor, and if screw piles are used in the structure, then you can simply abandon the excavation work. There are several varieties of this tool: TISE-F, TISE-2F, TISE-3F.

On one side the drill has a soil accumulator, and on the other there is a crossbar with handles. A folding plow is mounted above the soil accumulator. When drilling, the plow cuts off part of the earth. Under the influence of its own weight, the plow cuts the soil, gradually lowering down. The cut soil falls into the storage tank and rises to the top. This drill weighs 11 kg. When drilling, direction should be taken into account.

If, for example, you need to drill a well deeper, then the drill must be rotated clockwise. If anchor extension is required, the tool is rotated counterclockwise.

Sod should be removed before drilling. Depending on the type of soil, drilling can be done either by one person or by two people. A partner is involved if drilling occurs on clay or dense soils.

Grillage installation

A grillage made of I-beams is highly expensive and difficult to install.

A grillage is a part of a pile foundation that combines load-bearing elements into one structure. They are made in the form of a strip or in the form of a slab. If a wooden structure is being erected, then the functions of a grillage are performed by the crown of beams located in the lower part. The steel system is based on I-beams. But such a pile monolithic foundation has several disadvantages. Firstly, a monolithic pile foundation, in which I-beam products are used, is highly expensive. Secondly, the installation process itself is labor-intensive and requires the use of special equipment. It is impossible to mount this part of the foundation manually. Thirdly, even steel treated with a special solution will soon corrode. Therefore, the only method left is using reinforced concrete. In this case, the grillage can be prefabricated.

The types of grillage designs vary, depending on the position in relation to the ground. The first type is tall. This is the most popular type and is located 0.1-0.15 m above ground level. This distance is quite enough to reduce the impact of the soil on the connecting system during heaving. Swelling of the soil due to weather changes is accompanied by raising the grillage and tearing out the pile elements. It is also possible to tear off the structures themselves from the piles. But a height of 0.1-0.15 m allows you to avoid such problems.

Pile foundations come with a low, raised or high grillage.

A monolithic pile foundation with a high grillage has one drawback - the free space between the floor covering and the soil. In this regard, additional thermal insulation is required.

Another type of grillage is an elevated one. The base of the system is located on the soil. Unlike the previous type, here there is no free space between the floor and the soil. To prevent the effect of heaving on the structure, part of the soil is removed from under it - approximately 0.1-0.15 m.

The next type of grillage is recessed. It is made below ground level and some soil is also removed from under the lower part.

The main task of the grillage is to connect all the piles into one system. The structure does not distribute any loads over the ground. It simply applies pressure to the piles. The grillages are not mounted directly on the ground so that sections of the base do not come off due to soil heaving.

Foundation reinforcement

Foundation reinforcement increases the strength of concrete.

Mandatory reinforcement of the foundation with a monolithic grillage solves a number of useful problems. The resistance of concrete to bending loads increases. Without reinforcing elements, the grillage may crack. All reinforcement work consists of creating two belts. The first chord is located at the top, and the second at the bottom, and each uses at least two reinforcements. The diameter of the reinforced rods should be within 1-1.2 cm. The rods neutralize the deformation effect.

Transverse reinforcement has nothing to do with the load. Its purpose is to knit the entire structure in unified system. Since there is no pressure here, reinforcement with a diameter of 0.6-0.8 cm is used. In addition, smooth reinforcement products can be used.

The reinforcement cage must be completely buried in the concrete mixture. Only the very top section should protrude 2-5 cm. Such belts are a kind of mesh, which consists of ribbed reinforcement. There should be a step of 0.2-0.4 m between the elements. Due to the vertical rods, the upper and lower sections are combined into one structure.

It is important to note that the construction of a foundation with a grillage requires more concrete mixture than for other types of foundations. Before pouring, formwork is installed, into which the reinforcement frame is mounted. To ensure that the steel structure is properly immersed in the concrete mixture, bars are placed under the lowest bars. All elements must be securely fastened.

Reinforcement is also used to reinforce piles. This is necessary to connect to the grillage and strengthen the concrete. To attach the grillage to the piles, surface rods are attached to a frame made of reinforcement. The width of the grillage is made larger than that of the walls, and the cross section is made in the form of a square.

Construction of the basement

After the pile monolithic foundation is built, we proceed to finishing the base. The upper edge of the basement trim is attached to the bottom of the house and is protected from above by a special galvanized canopy (shimmer). From below, the finishing does not reach the ground by a few centimeters. This is done so that during soil heaving the base is not subject to deformation. To remove precipitation, drainage is installed and is also made with a width of about 70 cm. The most The best decision for a blind area around the entire perimeter of the house - this paving slabs. It is durable, aesthetic and repairable.

Didn't find the answer in the article? More information