Drivers know that the car's expansion tank stores coolant, without which the engine will not work for a long time. On top of the expansion tank there is a neck through which antifreeze is poured. To prevent it from spilling out when the car is moving, the neck is closed with a lid. It may seem that its structure and tasks are quite simple, but this is not entirely true. The expansion tank cap is an extremely important element of the engine, which must be monitored so that expensive engine components do not fail.

Table of contents:Tasks of the expansion tank cap

Engine operation is accompanied by heating, which is quite natural, given the processes taking place in it. As the engine components heat up, the coolant also heats up, which takes away some of the heat. An increase in liquid temperature is accompanied by its expansion and increase in pressure. Accordingly, the more the engine warms up, the greater the pressure that appears in the cooling system where the antifreeze or antifreeze is located. To prevent rupture of pipes, radiator, pipes and other elements of the cooling system when pressure increases, an expansion tank cap is needed, which not only performs a locking function, but also acts as a valve.

Engine operation is accompanied by heating, which is quite natural, given the processes taking place in it. As the engine components heat up, the coolant also heats up, which takes away some of the heat. An increase in liquid temperature is accompanied by its expansion and increase in pressure. Accordingly, the more the engine warms up, the greater the pressure that appears in the cooling system where the antifreeze or antifreeze is located. To prevent rupture of pipes, radiator, pipes and other elements of the cooling system when pressure increases, an expansion tank cap is needed, which not only performs a locking function, but also acts as a valve.

A warm engine operates at different temperatures. For some cars, the normal value is 95-100 degrees Celsius, for others the value reaches 125-130 degrees, and these indicators are also not maximum. At such temperatures, the coolant expands by approximately 20-30%, and accordingly, serious overpressure occurs. It is generally accepted that normal pressure in a car’s cooling system is 1.1-1.5 atmospheres, and if it is exceeded, problems may begin. Unpleasant situations also arise when the vehicle pressure is low, which is manifested by the creation of a vacuum inside the system and compression of pipes, hoses and other elements.

A properly functioning expansion tank cap eliminates the possibility of creating high and low pressure in the system, due to which it remains at the required level.

How the expansion tank cap works and works

Since the main tasks of the cap are to create the necessary pressure in the system and retain coolant in it, it must fit tightly to the edges of the tank onto which it is screwed.

Since the main tasks of the cap are to create the necessary pressure in the system and retain coolant in it, it must fit tightly to the edges of the tank onto which it is screwed.

A pressure regulating valve is built inside the direct cover. It plunges into the expansion tank and performs the task of releasing or pressurizing, depending on the need.

Note: In modern foreign cars, one physical valve is responsible for the functions of bleeding and pressurizing, while on old Russian cars there are two valves, each of which copes with its task.

As long as the pressure in the cooling system is within normal limits, the valves on the expansion tank cap do not operate. As soon as the pressure goes beyond the limit values, they perform one or another function.

Signs of a faulty expansion tank cap

It is quite difficult to identify a malfunction of the expansion tank cap, and serious malfunctions with engine components can occur due to problems in the operation of the valve. The following main symptoms of a malfunction can be identified:

- Smoke from under the hood. Most often it appears when coolant hits a hot intake manifold. In such a situation, the engine temperature will be at normal level. The problem manifests itself when the valve malfunctions, which should lower the pressure when it is exceeded. It begins to release pressure before peak values, which leads to a splash of antifreeze;

- Engine overheating due to cold air from the heater. If such a symptom is present, it indicates a failure of the low pressure valve. Problems will arise with it air jams in the cooling system, which will lead to engine overheating.

Also, symptoms of a malfunction of the expansion tank cap can be considered failure of clamps, rupture of tubes, radiator and other elements of the cooling system, including the tank itself. If traces of coolant begin to appear on the connecting elements, this indicates excess pressure in the system and the need to replace the expansion tank cap.

How to check the expansion tank cap

Checking the expansion tank cap is a rather complicated procedure, given that its operation directly depends on pressure, which is not so easy to create. Service centers have pressure pumps capable of pumping the required number of atmospheres, after which they can check whether the valve operates or not.

As for checking the expansion tank cap yourself, it is less accurate in terms of results, but it allows you to detect a fault in most cases. The cover is checked as follows:

Another way to check the expansion tank cap, which cannot always be used due to different engine designs and locations of cooling system hoses. It involves unscrewing the cap and squeezing one of the thick hoses. After this, the lid is screwed into place. The compression point of the hose is released, and if it returns to its original shape, then there are no problems with the valve in the cover.

Many people know that a car heats up during engine operation and requires constant cooling, especially in the hot season. Absolutely every car has a cooling system installed. An integral part of this system is the expansion tank. It serves to allow excess and spent vapors to escape into it. You can add coolant through the reservoir cap and monitor its condition if there is no special sensor.

What is this tank?

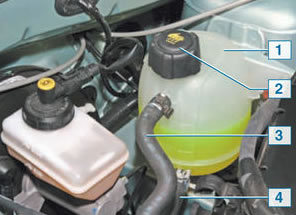

First you need to determine what an expansion tank is and what it does in the operation of the car. Most often this is a plastic container with hoses coming out of it. It is often equipped with a sensor that shows the coolant level. This plastic container is screwed on with a lid in which a valve is installed.

The valve serves to regulate the pressure in. The fact is that this system is completely sealed and when heated, increased pressure is created, which accumulates in the expansion tank, because it is highest point the entire system.

When pressure accumulates, a valve installed in the lid releases excess air. As the car cools, the pressure decreases, and the same valve sucks the required amount of air into the system.

This cover must be properly maintained, otherwise it will not perform as well.

Basic functions of the tank

The main function of the reservoir is to remove excess coolant and excess pressure for storage while the engine warms up. This happens due to the fact that during heating the volume of liquid and pressure in the entire system increases. Due to heating, the liquid expands, the pressure increases and begins to rise to the top point of the system according to the same principle as in the heating system of a house.

The highest point of the system, as already mentioned, is this expansion tank. It should be noted that the liquid increases only while it is heated by the engine; after it cools down again after stopping the engine, it will all drain into the radiator. In order not to overfill the liquid, there are special marks on the body of this plastic container. You need to fill according to the following principle. You cannot fill liquid above the maximum mark and below the minimum mark, this can lead to various problems.

The second function of this device is to remove steam that accumulates as a result of evaporation of liquid. This is done by the lid, which has a special valve that, if necessary, releases and sucks in air.

There are also cooling systems in which the radiator cap is responsible for releasing air and excess heated antifreeze or antifreeze. In such engine cooling systems, the expansion tank is not considered an important part.

Tank malfunctions and their elimination

The most basic malfunction is considered to be leakage of this tank. There may be several reasons for this malfunction.

- It often drips at the hose connections. In order to eliminate this malfunction, you just need to replace the clamp or the entire hose. In order to replace the clamp, no special effort is required, and this can be done even in the yard, but in the case of a hose it will be a little more difficult.

- The second reason for liquid leakage may be a broken tank. A hole in the tank may occur due to improper handling or impact of the housing. Also, the body of the tank could be pierced if the lid does not work properly and does not bleed air, which is why the tank expanded and cracked either at a seam or in a weak spot. In order to eliminate this malfunction, you need to purchase a new tank and install it. It is worth paying attention to the fact that if you solder the expansion tank, then next time the same thing will happen to the system, only with more dire consequences.

The second malfunction is considered to be a non-functioning valve in the lid; this can only be corrected by replacing it with a new one. In order to replace it, it does not require much effort and time; you just need to purchase a new cover and screw it in place of the old one.

It is worth paying attention to the fact that this should only be done on a cooled car, otherwise you may get burned.

Summing up

After reading this article, you can learn a few lessons for yourself and not repeat the mistakes that other car owners have made. The main thing to know is that new coolant should only be poured onto a cooled engine, otherwise this may lead to deformation of the engine itself or the cooling system.

You should also constantly pay attention to the cooling system and constantly look at the readings of the sensors, and if they are not there, then often unscrew the tank cap and monitor the pressure. Proper care and constant monitoring of the performance of all components of the car can contribute to rare visits to car service centers and spare parts stores. There is no principle of communicating vessels, so the liquid rises to the top.

How many interesting articles have been written about thermostats, pumps, radiators... But the expansion tank received only passing attention. But when you are desperately struggling with air jams in winter in order to get the heater in your car to work, or you are wondering why suddenly the arrow on the engine temperature sensor is desperately approaching the red limit or does not reach the working limit, do you think about why this happens, and what is the reason... Therefore, today we will talk about what troubles are hidden in the expansion tank, and how to avoid them.

What is an expansion tank?

Expansion tank with a closed lid This is a kind of plastic container with rubber hoses, with or without a coolant level sensor, as well as a pressure bypass valve built into the plastic lid. It is with this most insignificant detail at first glance, like a lid with a valve, that we will deal.

Why is she even needed? It's all about the coolant. The operating temperature of engines from domestic manufacturers, as a rule, is 90-95 C, and in order for the coolant not to boil while circulating in the system, its boiling point must be much higher, approximately 130 C. Therefore, coolant is initially created with elevated temperature boiling.

Also very important is maintaining high blood pressure in the engine cooling system (ECS), greater than atmospheric pressure, since pressure is a necessary condition for increasing the boiling point.

The working pressure in the OSD of domestic cars is, as a rule, 1.0 kgf/cm2, and of imported cars - about 1.5 kgf/cm2. Since the efficiency and operating temperature of imported car engines is higher and equals approximately 100-105 C, the pressure in the system should be higher.

“What does a cap in the expansion tank actually have to do with pressure?” - you ask. The most direct...

Operating principle of the expansion tank cap

Expansion tank, exhaust valve. When the engine heats up, the coolant also heats up. In this case, since the SOD is absolutely sealed, excess pressure is created. The entire SOD begins to expand, and excess air accumulates at its highest point - the expansion tank. Next, under the influence of compressed air, the outlet valve of the expansion tank opens and excess air escapes.

When the engine cools down, the reverse process occurs. The pressure in the system drops, and in order to avoid decompensation, that is, a decrease in the pressure level in the tank below atmospheric pressure, the inlet valve opens and sucks air into the system.

It often happens that drivers do not pay special attention to this small cap. As a result, gradual clogging and even corrosion occurs. The valve stops functioning correctly.

Consequences of incorrect operation of the expansion tank cap valves

If the valve in the tank has rusted and crumbled, then the tightness of the entire SOD is compromised. Excess air begins to freely enter and leave the system, forming air jams. Which, in turn, provoke engine overheating, depressurization of the SOD, failure of its parts and non-functioning stove in winter.

If the valve is clogged, it will also not function. This leads to the formation of excess pressure and, as often happens, depressurization of the SOD. If it is completely depressurized, the pipes are torn off, which can lead to the engine boiling. If it is partial, radiators leak, seals leak, pipe clamps become loose, the thermostat and, less often, the pump fail, etc.

The correct operation of the valve can be checked very simply. First, inspect it, and if you don’t notice any dirt or rust, then just press it with your finger. When the internal plastic valve is working properly, you will hear a sucking sound when you release the valve when you hold the cap to your ear, and a whistling sound of air escaping when you press down.

So, from all of the above we want to draw a conclusion. As popular wisdom says: “The spool is small, but expensive.” Do not neglect such a small but very important detail as the cap of the expansion tank of the engine cooling system. By periodically looking under it, you will be able to avoid many subsequent problems. Good luck on the road!

Generates a large amount of heat. At the same time, it is important to maintain the temperature of the unit within specified limits for maximum efficient fuel combustion, reducing exhaust toxicity, increasing service life, etc.

In other words, you can’t both cool the engine too much and allow it to overheat. To maintain the required operating temperature, modern engines use a combined system that combines liquid and air cooling.

In the design of a liquid cooling system, an important element is the expansion tank. Next we will talk about what the expansion tank is for, what its main purpose is, and what malfunctions of the expansion tank of the engine cooling system are most common.

What is the purpose of and where is the expansion tank of the engine cooling system located?

So, just open the hood to find the indicated tank. As a rule, this element is always visible so that the driver can easily monitor the coolant level and top up if necessary. On different cars, the tank can be installed to the left or right of the power unit, closer to the engine shield or further from it.

The main function of the tank is to compensate for the changing volume of coolant. This effect occurs as a result of changes in the temperature of the liquid. The design of the cooling system may differ; in some cases, the tank is a simple container for excess liquid, while in others it is a whole device capable of regulating the pressure in the system.

An expansion tank is necessary for the liquid system on modern internal combustion engines. The fact is that coolant (antifreeze, antifreeze) is an aqueous solution based on ethylene or propylene glycol. This liquid has a higher coefficient of thermal expansion compared to water.

Simply put, pour such liquid into the radiator, after the internal combustion engine is heated and it reaches operating temperatures, the liquid will also heat up and expand. It turns out that excess is actually formed, pressure increases, etc.

If you turn off the engine, after the coolant cools down, the volume of liquid decreases again, and a vacuum is created in the system. This causes outside air to be drawn in through the valve in the radiator cap. It is quite obvious that in this case, air pockets will be created, which will cause heat transfer disturbances, incorrect operation of the cooling system, etc.

To prevent this from happening, a separate container (cooling system tank) is installed into which excess hot coolant from the radiator is collected. Also, the presence of liquid in the tank avoids the creation of vacuum and the formation of air jams, since when the volume decreases as a result of cooling, the liquid from the tank fills the voids.

Today, designers have gone even further by moving the bypass valve, which was previously in the radiator cap, to the expansion tank cap. It turns out that the release of pressure and excess antifreeze when boiling occurs through the tank cap. In other words, the tank took on the function of the upper part of the radiator and ceased to be a simple reservoir.

As mentioned above, the tank can be installed in different places in the engine compartment, but the location of its installation must be implemented in such a way as to achieve the effect of communicating vessels. The tank and radiator are connected using pipes.

This solution allows access for excess hot antifreeze to the expansion tank. When the coolant cools, it is also possible to compensate for the missing volume in the system by receiving fluid from the tank. This scheme prevents air from entering the radiator and the formation of air locks in the system.

Expansion tank device

Structurally, this container is very simple. The material used is translucent plastic. Also, a sensor can be additionally built into the tank, which signals the driver about a critical decrease in the coolant level.

The top of the tank is closed with a lid in which a valve is installed to regulate the pressure. If the pressure in the system increases, then the valve operates.

Also on the wall of the tank there is a level indicator in the form of “minimum” and “maximum” marks, allowing you to control the liquid level. It is important to understand that on a cold engine the level should not fall below the minimum. The maximum level must also not be exceeded.

As for the tank cap with the valve, it seals the container hermetically on a cold internal combustion engine. However, when the engine reaches operating temperature and the coolant heats up, the pressure in the cooling system and in the tank naturally increases.

If the pressure rise reaches an average of 120 kPa, the valve opens. When the pressure drops to an average of about 83.4 kPa, the valve closes. This operation of the valve is necessary in order to avoid rupture of pipes, damage to the radiator, etc.

At the same time, after the engine cools down, the pressure in the system begins to drop, the volume of coolant decreases and a vacuum is created. When the pressure drops, on average, below 3 kPa, the inlet valve of the expansion tank opens to take in air. As a result, the pressure difference is leveled, and the missing volume of liquid is compensated from the tank.

Common faults

Typically, most problems are not related to the container itself. Not so often there are cases when the tank itself cracks and begins to leak for no obvious reason. However, even taking into account the simple design, the problem part may well be the cap of the expansion tank of the engine cooling system.

The valve built into the lid may fail. Insufficient sealing may also occur due to deformation of the rubber ring. As a result of such malfunctions, the cap may begin to leak antifreeze, the system may become airy, etc.

If the valve in the cover begins to work incorrectly, then in such a case deviations in the operation of the internal combustion engine cooling system are inevitable. In addition to the formation of air locks, this situation in some cases leads to a critical increase in pressure and rupture of the expansion tank. In such a situation, the tank needs to be replaced with a new one. It is not recommended to attempt to restore a damaged container by sealing cracks.

If we talk about the cover, its damage and defects, as well as malfunctions of the valves due to clogging or deterioration, are a reason to replace the cover. In some cases, the lid is cleaned in an attempt to restore functionality, but this method does not always work. Given the low cost, it is better to replace the element immediately.

What's the result?

As you can see, in the design of a modern car, increased demands are placed on the engine cooling system and its correct operation. For this reason, for efficient operation, a special tank is additionally used in the design.

You also need to know that if the specified expansion tank of the engine cooling system is involved in the circuit, it is highly advisable to fill the system only with antifreeze or antifreeze, and not water. As for breakdowns, if pressure increases in the cooling system or air pockets form, special attention must be paid to the expansion tank cap.

Malfunction of the valves in the cover often leads to damaged pipes, the thermostat fails faster, the pump suffers, the engine may overheat, etc.

The expansion tank has become a common car part since the active use of non-freezing liquids, including antifreeze and antifreeze, began to be used, however, given the specifics in which it functions, such a problem as “how to seal the expansion tank” also becomes relevant over time.

In order to understand this issue, you should delve a little into the specifics.

Thus, the basis of the liquids used in the expansion tank are aqueous solutions of dihydric alcohol (ethylene glycol), their feature is an increased coefficient determined for thermal expansion (compared to water).

Taking this into account, the liquid poured into the system undergoes expansion during engine warm-up, which leads to its squeezing out through the safety valve located in the radiator cap.

When the engine is turned off and begins to gradually cool down, the volume of liquid decreases, which leads to a vacuum in the cooling system.

Naturally, this activates the lid valve, which leads to air being sucked into the radiator, which leads to a disruption in the heat removal process, and the danger of overheating is probably known to everyone.

In order for liquid, rather than air, to get inside, an additional reservoir is required, which, in fact, is the expansion tank.

Using a hose, it was connected directly to the filler neck in the radiator, positioned so that the middle approximately coincided with the level of the upper edge of the radiator.

This design squeezes excess heated fluid into the tank; as the engine cools, it refills the system, while preventing air from entering.

By the way, by installing an expansion tank, the problem associated with environmental pollution was also solved.

Returning now directly to our question of how to seal the expansion tank, we can note that only replacing it will save the situation.

This is explained by the fact that not a single glue is able to withstand the pressure exerted by a liquid brought to a temperature of a hundred degrees.

In addition, some car models maintain operating temperature exactly within the specified temperature, or even higher.

Accordingly, for antifreeze and antifreeze the boiling point is determined to be almost 103°C, while due to the tightness that characterizes the cooling system as a whole, when the pressure in it increases, the liquid may not boil even at 115°C.

Taking this into account, if there is a crack, then the liquid will not only begin to flow out, but also, due to depressurization, its boiling point will significantly decrease.

Repair of radiator and expansion tank

In this article I want to tell you what to do if the radiator or expansion tank is leaking. First you need to figure out why this happened. Almost all cooling systems have pressure, sometimes up to 2 atmospheres depending on the make of the car. Overpressure The expansion tank (or radiator) cap must be reset. If the lid becomes sour, the pressure begins to increase, causing the plastic to crack. and sometimes honeycombs in the radiator. In newer car models, it is almost impossible to check the expansion tank cap because... the valve itself is rolled into a plastic case, and a special pressure gauge for checking pressure in cooling systems is not found in every car service center. Therefore, if the expansion tank (or radiator) cracks on its own (without mechanical impact), the first thing I recommend is replacing the cap. It costs around 5 dollars, although there are very expensive exceptions.

Now about the repair itself. The plastics from which expansion tanks and radiators are made do not react with more than one glue, so it will not be possible to glue them together properly. If you need to eliminate the leak for some time, you can clean the crack with sandpaper, degrease it with a solvent and fill it with poxypol or seal it with cold welding. If everything is done well, it will last for several months. The whole problem is that the plastic in the cooling system, due to temperature changes, contracts and expands. Therefore, no matter how well you glue it together, it will still leak over time.

The most reliable, in my opinion, the only way to repair plastic in the cooling system is welding. Almost all expansion tanks are made of PP polypropylene or PE polyethylene. They cook very well; in my experience, not one has yet leaked after repair. It is better to take not a bumper as a donor, but something more rigid, such as fender liners. It’s more difficult with radiators; they are made from pa66. This is one of the hardest and most refractory plastics. The repair of such plastic must be approached very carefully, otherwise it will have to be redone. Below there will be a video of repairing an expansion tank from ra66, these are very rare and in terms of the complexity of the repair they do not differ from radiators. As a donor, I took the body from a broken drill.