The amount of purified air in the room will depend on the calculation of the power of the kitchen hood fan.

But external beauty is not the most important thing. The main task of this device is to rid the kitchen of odors, burning, soot and grease that appear during cooking. Exhaust ventilation removes fumes emanating from various types of heating devices. It prevents the appearance of dirty deposits on the ceiling and wall surfaces. This allows you to perform cosmetic repairs much less frequently, which will save a significant amount of money. It will also take less time to carry out general cleaning.

A device capable of passing a certain amount of air through its filters can cope with the task of cleaning the atmosphere in a room. And for this you need to select a device with a fan of the required power. How to calculate the power of a device?

An example of calculating the performance of a kitchen hood fan.

- Using a tape measure, measure the size of the kitchen and determine its volume in meters. To do this, the length must be multiplied by the width and height. The BTI documents indicate the area of the premises. Example: the area of the kitchen area is 10 m². The height from floor to ceiling is 3 m. We multiply the area by the height and get 30 m³. This is the size of the kitchen.

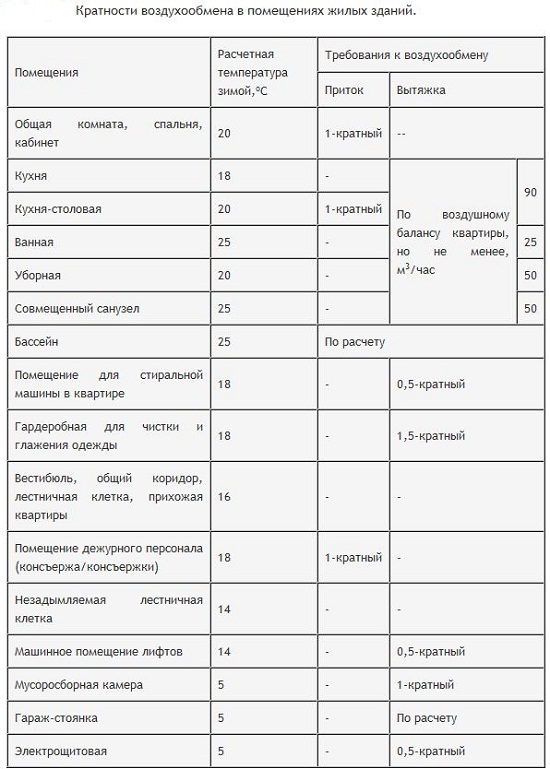

- Next, the value characterizing air exchange is calculated. To do this, you need to multiply the volume of the kitchen by the number of complete air updates per hour. Building codes and regulations (SNiP) provide for an air exchange rate of 10-12. Thus, to calculate the capacity of the exhaust system, you need to multiply 30 m³ by 12. The result is a figure of 360 m³/hour. This much air must be renewed every hour.

- To carry out exchange in such a volume, you need a fan with a power of 400-800 m³/hour. But standard ventilation ducts can only pass about 180 m³. Therefore, a fan will not help much here.

- In this case, a recirculation exhaust system will help, which passes air through filters and sends it back into the room. Overcoming the resistance of the filters also requires power. Therefore, 40% should be added to the calculated figure. The result will be 560-1120 m³. This should be the power of the hood fan in a kitchen measuring 30 m³.

- In some cases, you can do without a ventilation duct. To do this, the exhaust fan is installed in a specially equipped opening in the wall, in the ceiling or at the junction of the ceiling and wall. This installation allows the use of a less powerful fan.

This is just a simple calculation of the required exhaust fan power. If the kitchen does not have doors, then you also need to take into account the volume of the adjacent room. So, the formula for calculating fan power for general cases is: room width x length x height x exchange rate = required value. You can calculate the volume of a room without special problems. It is enough to measure the length, width and height and multiply them.

Multiplicity for premises different types is defined like this:

| Room type | Multiplicity |

| Bakery | 20-30 |

| Greenhouse | 25-50 |

| Office | 6-8 |

| Bathroom, shower | 3-8 |

| Salon | 10-15 |

| Restaurant, bar | 6-10 |

| Bedroom | 2-4 |

| Lobby | 3-5 |

| Classroom at school | 2-3 |

| Cafeteria | 10-12 |

| A hospital room | 4-6 |

| Shop | 8-10 |

| Basement | 8-12 |

| Kitchen in a house or apartment | 10-15 |

| Gym | 6-8 |

| Attic space | 3-10 |

| Catering kitchen | 15-20 |

| Pantry | 3-6 |

| Changing room with shower | 15-20 |

| Laundry | 10-15 |

| Toilet in the house, in the apartment | 3-10 |

| Conference hall | 8-12 |

| Living room | 3-6 |

| Billiard room | 6-8 |

| Public toilet | 10-15 |

| Garage | 6-8 |

| Meeting room | 4-8 |

| Utility room | 15-20 |

| Library | 3-4 |

| Dining room | 8-12 |

Table for calculating the minimum performance of the hood relative to the volume of the kitchen.

The highest multiplicity is chosen for use in rooms with many people, high humidity and temperature, a lot of dust and strong odors. In a kitchen with an electric hob, you can choose a lower value, with gas stove– bigger. This is due to the fact that gas emits combustion products when the stove is turned on. The fan, selected taking into account the above data, can be mounted in a wall, window, or ceiling of the room.

Another way to determine the power of a device

You can calculate the fan power using a different principle. The multiplicity indicator remains unchanged, and instead of volume, the number of people in the room is taken. The calculation formula is very simple: L = N x Lн. Values in this formula:

- L – required fan power;

- N – number of people in the room;

- Lн – standard air flow per person.

Standard air flow depends on the type of human activity and is measured in m³. Its average values are:

You should not buy a hood with a much higher fan power than was designed, as it will create more noise.

The selection of a fan must be made not only by its power, but also by the type of design of this unit. To operate in clean air conditions at temperatures below 80°C, it is customary to install conventional exhaust fans. To remove air with a temperature above this value from the room, install a heat-resistant fan. In aggressive and explosive environments, it is better to use the device in a special anti-corrosion version. Its components and parts do not react in any way with the environment.

To remove contaminated air from the bathroom, it is recommended to use a splash-proof exhaust fan. It prevents moisture from entering the air duct and protects the device and the electrical network from short circuits.

Equipping residential and industrial premises with exhaust ventilation is a prerequisite for ensuring comfortable living conditions for people. There are many types of fans for this purpose. They have different sizes, power, capabilities. Their correct choice is the key to the health and long service life of indoor furniture.

WHAT HIGH SHOULD THE VENTILATION PIPE BE?

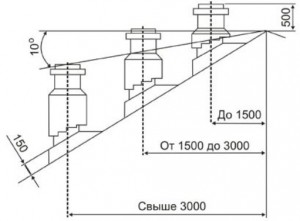

1. The height of the ventilation pipe above the roof located next to chimney, must be equal to this pipe.

2. Above flat roof the pipe must rise to a height of at least 500 millimeters.

3. If the pipe is located at a distance of no more than one and a half meters from the parapet, or from the ridge, its height above the roof ridge should be more than 500 millimeters.

4. If the pipe is located from the parapet or from the ridge at a distance of 1.5-3 meters, its height should not be lower than the roof ridge.

5. The ventilation pipe, located at a distance of more than three meters from the ridge, must be no lower than a line drawn approximately downward from the ridge of the roof towards the horizon line. This line must be drawn at an angle of 10 degrees.

HOW TO CALCULATE THE EXACT HEIGHT

To determine the exact height of the ventilation pipe above the roof, it is enough to know its diameter. Next, depending on the diameter, the height is calculated using the table below.

![]()

The required pipe height is indicated in the horizontal line at the top. It is indicated in millimeters. The vertical column on the left shows the width of the pipes. The cells indicate the equivalent diameters of the air ducts, mm.

METHODS FOR CALCULATING PRESSURE LOSS IN A VENTILATION PIPE

In addition to the height of the pipe, the pressure loss occurring in the duct is also calculated. Several formulas are used for the calculation:

In addition to the height of the pipe, the pressure loss occurring in the duct is also calculated. Several formulas are used for the calculation:

The task of ventilation is to remove old stale air from the room and necessarily replace it with fresh street air. Only adequate ventilation can ensure the creation and maintenance of favorable conditions for human body atmosphere. When thinking about how to calculate ventilation in a room, you need to understand that in addition to its main purpose, it is the key to maintaining dryness for house structures. It is the correct operation of this system that will not allow rot and mold to form on the surface of the walls, even in rooms with high humidity.

Properly designed ventilation is a prerequisite for creating an optimal microclimate in any modern home. Centralized heating, anti-draft equipment, careful thermal insulation - all this requires a scrupulous approach to the design of the ventilation system. The lack of constant air exchange leads to stuffiness. In turn, high levels of moisture in the room lead to condensation.

To calculate ventilation as correctly as possible, we can take as an example natural convection, which works to remove unpleasant odors and air with high humidity from rooms. Natural convection delivers warm air layers from the house to its roof. For such a wire, air duct pipes are used, through which the flows are directed through the ridge ventilation elements and then discharged outside. This type of ventilation is a self-regulating type. There are no fans, eliminating the need to use electricity.

Ventilation in the room must be mandatory. At the same time, modern technical designs, which include air purification from almost all street pollutants, are not as useful as they might seem at first glance. They are able to purify the street air so much that it becomes completely artificial and loses its natural properties and characteristics. That is why choosing a place to live is fundamental to creating a healthy atmosphere in a house or apartment. Clean air outside ensures the presence of clean natural air inside and eliminates the need for powerful air purification devices in ventilation systems.

Exhaust ventilation

The purpose of exhaust type ventilation is ventilation. In other words, such a structural structure contributes to the high-quality removal of already exhausted air flows from the premises and ensures their replacement with fresh flows from the street. Modern technical development allows, along with solving the main problem, to install air conditioning, heating-cooling, and filtration equipment in such systems. However, how necessary and expedient this is should be decided in each individual case.

Compliance with sanitary and hygienic conditions in the room can only be ensured by constant ventilation of the room atmosphere. Calculate correctly exhaust ventilation- means creating an environment in the building that is favorable for human well-being and health, which will meet all existing sanitary requirements. Exhaust ventilation is necessary to combat harmful emissions indoors. These emissions in a residential building can be defined as follows:

- dust;

- excess moisture (not only the bathroom, toilet, kitchen, dining room, but also living rooms are often characterized by high humidity);

- excess heat;

- vapors of harmful substances and accumulations of various gases.

Exhaust ventilation can be a whole system of different structural elements, the common purpose of which is the complete removal of used (exhaust) air from any premises. Checking its functionality is very simple: if after a walk you enter your apartment, and the feeling of freshness in it is no different from the sensations you experienced outside, it means that the exhaust ventilation of your home is working just perfectly.

Of course, this testing method is effective where the air around the house is clean, which is impossible in a polluted urban environment or near industrial enterprises. Thus, if upon entering the apartment you feel even a slight presence of an unpleasant odor or stuffiness, then the ventilation system needs to be checked for efficiency. If any problems are found, they must be corrected without fail. Remember that the human body tends to get used to the smells and atmosphere around it. However, even if you do not feel any obvious discomfort from consuming fresh air, it will continue to have the most negative impact on your well-being.

Forced ventilation

The task of supply ventilation is the uninterrupted supply of the required amount of fresh air to the building. At the same time, today's technologies allow this feed stream to be either warmed (in winter) or cooled (in summer). Supply ventilation can be either local or general.

The local system involves supplying air from the street to a specific place in the building, for example, to an area where air pollution is localized (kitchen stove, toilet). In this case, the exhaust ventilation is targeted, focusing on those areas of the room where the use of clean air occurs especially intensively. General ventilation is most acceptable in domestic conditions and is used everywhere. It's mechanical.

The design features of both supply and exhaust ventilation can be reduced to a duct or non-duct type. You can calculate the supply ventilation yourself. However, for this it is necessary to additionally determine the volume of the required fresh air supply, and suitable methods for processing the supplied flows: purification, heating or cooling, humidification (in winter) and calculate the ventilation pipes.

Supply ventilation in combination with an air purifier, for example, a photocalytic one, provides air layers into the room that do not contain the following:

- traffic fumes;

- industrial and household toxic organic compounds;

- allergens of animal and plant origin;

- soot and gases;

- unpleasant odors and smoke of tobacco origin;

- carbon monoxide, ozone, phenol, formaldehyde and nitrogen oxides.

However, such serious cleaning systems are justified only if your home is located in a really very polluted area of the metropolis or is located close to factories and manufacturing concerns. If you live in a quiet suburb or surrounded by gardens and woods, using powerful air purifiers becomes impractical.

Calculation of indoor air volume

Recommendations from specialists will help you figure out how to calculate ventilation in a room. It is advisable to entrust the creation of such a project and its full calculation to a professional OV designer. His competence will allow you to save on finances, time and nerves, and will also help you choose the most appropriate type of ventilation, and will tell you which additions to the system need to be installed and which are not necessary.

Before giving preference to one or another type of equipment, you need to calculate the volume of air in the room. Knowing the required amount of air, you can begin to select equipment, which is also calculated depending on certain parameters:

- Heater power indicators.

- Air flow performance indicators.

- Indicators of air speed and cross-sectional area of air duct structures.

- The level of pressure created by the fan during operation.

- Noise level.

You can determine air consumption by measuring the consumption of cubic meters per hour. This work will require a floor plan of the premises indicating their purpose and with an explanation.

Calculations begin by determining the air flow rate required for each specific room. In other words, calculations are carried out showing how many times a complete air exchange takes place in the rooms within 60 minutes. These calculations largely depend on the area of the object. So, for example, in a room with an area of 50 m2 and a ceiling height of 3 meters, the total volume is 150 m3, which provides double air exchange, which is equal to 300 m3 in one hour. It must be remembered that in many respects the rate of air exchange directly depends on the power level of the equipment that produces heat, as well as on the number of people constantly in the rooms and on the direct purpose of these rooms.

It is not always possible to invite a specialist to design the system utility networks. What to do if during the renovation or construction of your facility you need to calculate the ventilation air ducts? Is it possible to produce it on your own?

Calculation of ventilation and air ducts for it will allow you to create an effective system that will ensure uninterrupted operation of units, fans and air handling units. If everything is calculated correctly, this will reduce costs for the purchase of materials and equipment, and for further maintenance of the system.

Calculation of ventilation system air ducts can be carried out using different methods. For example, like this:

- constant pressure loss;

- permissible speeds.

Types and types of air ducts

Before calculating the networks, you need to determine what they will be made of. Nowadays, products made of steel, plastic, fabric, aluminum foil, etc. are used. Air ducts are often made of galvanized or of stainless steel, this can be organized even in a small workshop. Such products are easy to install and calculating such ventilation does not cause problems.

In addition, air ducts may vary in appearance. They can be square, rectangular, oval. Each type has its own advantages. Rectangular ones allow you to make ventilation systems of small height or width, while maintaining the required cross-sectional area. Round systems have less material; oval systems combine the pros and cons of other types.

For an example of ventilation calculation, let’s choose round pipes made of tin. These are products that are used for ventilation of housing, office and retail spaces. We will carry out the calculation using one of the methods that allows us to accurately select the air duct network and find its characteristics.

Method for calculating air ducts using the constant velocity method

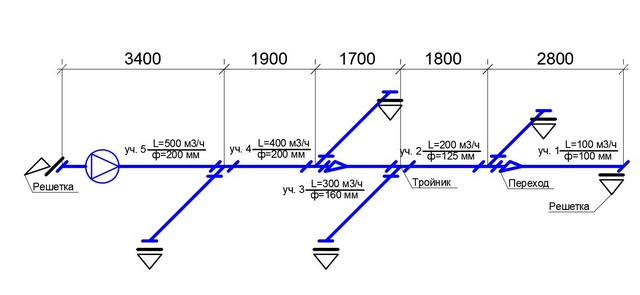

The calculation of ventilation air ducts must begin with a floor plan. Using all standards, they determine the required amount of air in each zone and draw a wiring diagram. It shows all grilles, diffusers, cross-section changes and bends. The calculation is made for the most remote point of the ventilation system, divided into areas limited by branches or grilles.

Calculation of an air duct for installation of a ventilation system consists of selecting the required cross-section along the entire length and finding the pressure loss for selecting a fan or supply unit. The initial data are the values of the amount of air passing through the ventilation network. Using the diagram, we will calculate the diameter of the air duct. To do this you will need a pressure loss graph.

The schedule is different for each type of duct. Typically, manufacturers provide such information for their products, or you can find it in reference books. Let's calculate round tin air ducts, the graph for which is shown in the figure.

Using the chosen method, we set the air speed of each section. It must be within the limits of the standards for buildings and premises of the selected purpose. For main supply and exhaust ventilation ducts, the following values are recommended:

- residential premises – 3.5–5.0 m/s;

- production – 6.0–11.0 m/s;

- offices – 3.5–6.0 m/s.

For branches:

- offices – 3.0–6.5 m/s;

- residential premises – 3.0–5.0 m/s;

- production – 4.0–9.0 m/s.

When the speed exceeds the permissible limit, the noise level increases to a level that is uncomfortable for humans.

After determining the speed (in the example 4.0 m/s), we find the required cross-section of the air ducts according to the schedule. There are also pressure losses per 1 m of network, which will be needed for the calculation. Total losses pressure in Pascals is found by multiplying the specific value by the length of the section:

Puch=Ruch·luch.

Network elements and local resistances

Losses on network elements (grids, diffusers, tees, turns, changes in cross-section, etc.) also matter. For grids and some elements, these values are indicated in the documentation. They can also be calculated by multiplying the coefficient of local resistance (k.m.s.) and the dynamic pressure in it:

Pm. s.=ζ·Pd.

Where Pd=V2·ρ/2 (ρ – air density).

K. m.s. determined from reference books and factory characteristics of products. We summarize all types of pressure losses for each section and for the entire network. For convenience, we will do this using the tabular method.

The sum of all pressures will be available for this duct network, and branch losses should be within 10% of the total available pressure. If the difference is greater, it is necessary to install dampers or diaphragms on the bends. To do this, we calculate the required k.m.s. according to the formula:

where Pizb is the difference between the available pressure and losses on the branch. Use the table to select the aperture diameter.

The required diaphragm diameter for air ducts.

Correct calculation of ventilation air ducts will allow you to select the right fan according to manufacturers’ schedules. Using the found available pressure and the total air flow in the network, this will be easy to do.

Comments:

- Duct sizing calculation

- Matching area and flow

- Calculations for the air heater

- Calculation of a natural channel system

In order for the ventilation system in the house to work effectively, it is necessary to make calculations during its design. This will not only allow you to use the equipment with optimal power, but also save on the system, fully maintaining all the required parameters. It is carried out according to certain parameters, while completely different formulas are used for natural and forced systems. Special attention should be paid to the fact that coercive system not always required. For example, for a city apartment, natural air exchange is quite sufficient, but subject to certain requirements and standards.

Duct sizing calculation

For the premises, it is necessary to determine what the cross-section of the pipe will be, the volume of air passing through the air ducts, and the flow speed. Such calculations are important, since the slightest errors lead to poor air exchange, noise of the entire air conditioning system or large cost overruns during installation and electricity for the operation of equipment that provides ventilation.

To calculate ventilation for a room and find out the area of the air duct, you must use the following formula:

Sc = L * 2.778 / V, where:

- Sc is the estimated channel area;

- L – value of air flow passing through the channel;

- V – value of air speed passing through the air duct;

- 2.778 is a special coefficient that is necessary to coordinate dimensions - these are hours and seconds, meters and centimeters, used when including data in the formula.

To find out what the actual area of the duct pipe will be, you need to use a formula based on the type of duct. For a round pipe, the formula is used: S = π * D² / 400, where:

- S – number for the actual cross-sectional area;

- D – number for the channel diameter;

- π is a constant equal to 3.14.

For rectangular pipes you will need the formula S = A * B / 100, where:

- S is the value for the actual cross-sectional area:

- A, B are the length of the sides of the rectangle.

Return to contents

Matching area and flow

The diameter of the pipe is 100 mm, it corresponds to a rectangular air duct of 80*90 mm, 63*125 mm, 63*140 mm. The areas of rectangular channels will be 72, 79, 88 cm². respectively. The air flow speed can be different, the following values are usually used: 2, 3, 4, 5, 6 m/s. In this case, the air flow in the rectangular duct will be:

- when moving at 2 m/s – 52-63 m³/h;

- when moving at 3 m/s – 78-95 m³/h;

- when moving at 4 m/s – 104-127 m³/h;

- at a speed of 5 m/s – 130-159 m³/h;

- at a speed of 6 m/s – 156-190 m³/h.

If the ventilation calculation is carried out for a round duct with a diameter of 160 mm, then it will correspond to rectangular air ducts of 100 * 200 mm, 90 * 250 mm with cross-sectional areas of 200 cm² and 225 cm², respectively. In order for the room to be well ventilated, the following flow rate must be observed at certain air mass movement speeds:

- at a speed of 2 m/s – 162-184 m³/h;

- at a speed of 3 m/s – 243-276 m³/h;

- when moving at 4 m/s – 324-369 m³/h;

- when moving at 5 m/s – 405-461 m³/h;

- when moving at 6 m/s – 486-553 m³/h.

Return to contents

Calculations for the air heater

A heater is equipment designed for conditioning a room with heated air masses. This device is used to create a more comfortable environment during the cold season. Heaters are used in a forced air conditioning system. Even at the design stage, it is important to calculate the power of the equipment. This is done based on the performance of the system, the difference between the outside temperature and the indoor air temperature. The last two values are determined according to SNiPs. It should be taken into account that the room must receive air whose temperature is not less than +18 °C.

The difference between external and internal conditions is determined taking into account the climate zone. On average, when turned on, the heater provides air heating of up to 40 °C to compensate for the difference between the warm internal and external cold flow.

I = P / U, where:

- I is the number for the maximum current consumed by the equipment;

- P – power of the device required for the premises;

- U – voltage for powering the heater.

If the load is less than required, then you need to choose a device that is not so powerful. The temperature to which the air heater can heat the air is calculated using the following formula:

ΔT = 2.98 * P / L, where:

- ΔT – the number of air temperature differences observed at the inlet and outlet of the air conditioning system;

- P – device power;

- L is the value of equipment productivity.

In a residential area (for apartments and private houses), the heater can have a power of 1-5 kW, but for offices the value is taken to be higher - it is 5-50 kW. In some cases, electric heaters are not used; the equipment is connected to water heating, which saves energy.

The main purpose of ventilation is to renew the air accumulated in the room. There are exhaust ventilation, which removes air, and supply ventilation, which supplies fresh air from the street; the third type is supply and exhaust ventilation, which provides both the removal of air from the room and the supply of fresh oxygen. Typically, this type of ventilation is installed in rooms where exhaust air accumulates (kitchen, bathroom) and a large number of people (restaurants, cafes), etc. It is worth noting that the installation of supply and exhaust ventilation is not such a simple matter, the system consists of many parts : air ducts, heater, cooler, sound absorber, filters, as well as sensors (carbon dioxide level, room temperature, etc.). Installation of supply and exhaust ventilation is quite complex and multi-stage, but with some skill and great desire, you can install supply ventilation with your own hands. Our article will tell you how to do this.

How to calculate supply and exhaust ventilation: device and system design

The supply and exhaust ventilation system consists of two parts: a supply ventilation system (provides the delivery of fresh air from the street, its heating, cleaning, and, if necessary, cooling) and an exhaust system (popularly simply “exhaust”, that is, a device that ensures the outflow of air from the room ). Exhaust ventilation has a fairly simple design (an air duct and a mechanism that ensures air outflow), it does not require the installation of filters, coolers or heaters, the only thing needed is a noise absorber - if the hood is quite powerful, it will create noise through its operation.

An important question that interests many consumers is how to calculate exhaust ventilation? To calculate the power of the device that removes air, you need to calculate the volume of the room in cubic meters. m. and then multiply by 12. Calculation of exhaust ventilation, example:

- kitchen area 2 X 3 m with a ceiling height of 2.5 m, the volume of the room is 15 cubic meters. m.

- extraction power 15 X 12 = 180 cubic meters. m/h

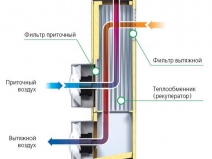

To improve the operation of the hood, it is recommended to open a window or vent. To make the ventilation system more economical, complex solutions are used. In winter, the air exhausted outside heats the air entering the room; for these purposes, a special unit is used - a recuperator - a kind of heat exchanger in which the air arriving from the street is heated. The design of the recuperator is such that the street air is heated without mixing with the air discharged outside.

Design of supply and exhaust ventilation is the stage from which the installation of a ventilation system begins. Before making the actual installation, it is necessary to calculate on paper how many meters of pipe are required for air outflow, how many air ducts are required for air inflow, where all the components and parts of the system will be located, where grilles and air intakes will be installed. At the design stage, you should take into account not only the location, but also the dimensions of the air ducts (pipe diameter); the larger the diameter, the greater the air flow that can be provided, however, modern housing rarely has high ceiling heights, so it will not be possible to install fairly wide pipes. The downside of narrow air ducts is high noise, so when calculating supply ventilation, a compromise is usually found between noise indicators and pipe sizes.

As for the power of air flow, the following calculations are usually carried out:

- Up to 3 cubic meters must be supplied to residential premises. m. per hour per 1 sq. m of housing,

- In public places it is necessary to supply 60 cubic meters. m./hour per person permanently staying in the building and up to 20 cubic meters. m. per hour per temporary visitor.

How to install a supply and exhaust ventilation system: example of calculation and installation

The installation of supply and exhaust ventilation is carried out at the stage of finishing work, after all the “dirty” construction work (plaster, putty) has been completed, but before the ceiling is mounted, since the bulk of the ventilation system components are hidden in the ceiling. The principle of ventilation is clear, but not everyone knows which units and components need to be installed. The arrangement of system nodes is as follows:

- Air intake valve,

- Air filter (cleaning intake air),

- Heater (heater) - usually this unit is turned on at low temperatures, when the outgoing flow does not have time to warm up the incoming flows.

- Recuperator - a block where the incoming flow is heated - this block is installed to save resources.

- A cooling unit or air conditioner, this unit is installed almost before the air exits the supply system in order to minimize the path of cooled air through the air ducts.

- If necessary, a humidifier and fan are installed along the flow path.

- If the power of the supply ventilation is quite high, then a noise absorber is also installed.

For the most efficient and economical operation of the ventilation system, an automatic control unit is installed that turns on/off various components (for example, in the summer, heating units are turned off and air cooling is turned on, in winter, on the contrary, the air is heated and not cooled).

Determination of ventilation power and efficiency

Is it possible to independently calculate the ventilation power?

In order to install a ventilation system, it is necessary to calculate the volume of air that will be supplied and removed from a certain room.

- according to the area of the premises - at least 3 cubic meters must be supplied to residential premises, regardless of the number of people staying there, in 60 minutes. m of fresh air per 1 sq. m. squares;

- according to sanitary standards - for one person constantly in the room per hour, 60 cubic meters are required. m. of fresh air, for a temporary stay - 20 cubic meters;

- by multiplicity - in SNiP 2.08.01-89* “Residential buildings” standards are given for the frequency of air exchange (a complete change of air in a room in 1 hour) for premises for various purposes.

The calculation of supply and exhaust ventilation using the third method is carried out according to the formula: the rate of air exchange rate in the room is multiplied by the volume of the room.

How to check the effectiveness of ventilation?

To make sure that the air exchange in the house/apartment is arranged correctly, it is necessary to check the operation of the ventilation hood. To do this, bring a sheet of paper or a lit match to the ventilation grille. If the edge of the paper moves towards the grate or the flame is directed towards ventilation duct, the exhaust system is working.

If this does not happen, it means the channel is clogged. The cause of its clogging can be leaves caught in the air duct or cobwebs. In this case, the channel should be cleaned.

The reason that the hood in the apartment does not work may be that the neighbors blocked the air duct during repairs. In this case, it is necessary to call a specialist to identify this place and resume traction.

If steam is poorly removed from the bathroom, it means that the exhaust fan was calculated incorrectly and a higher power unit is needed.

How to properly organize supply ventilation in an apartment?

Due to installation plastic windows which often cause condensation to form, bad environment, ordinary ventilation of the apartment is not effective. The way out of the situation is to install fresh air ventilation.

The air flow into the apartment can be increased by installing special valves on the balcony or loggia. Exhaust air will be discharged through ventilation grilles in the kitchen and bathroom.

But more effective way There will be installation of decentralized exhaust structures. These are separate air handling units that are mounted on the facade walls inside the apartment. Air exchange occurs through air ducts in the wall. The built-in heat recuperator will reduce the cost of heating the room by 70%, and the filter will clean the air. The simplicity of the unit allows you to install it yourself.

What is the advantage of a heat recovery ventilation system?

It is known that the supply and exhaust system, the operating principle of which is based on the supply of fresh air to the room and the removal of exhaust air, has a rather low efficiency. To increase it, the device is equipped with a heat recuperator - a mechanism that ensures energy saving in the house.

The operating principle of this type of ventilation is that the air leaving the room is not immediately discharged outside, but enters a special cassette. There it heats clean air coming from the street to room temperature.

The operating principle of this type of ventilation is that the air leaving the room is not immediately discharged outside, but enters a special cassette. There it heats clean air coming from the street to room temperature. Thus, not cold air enters the room, but heated, comfortable air. In addition, no additional energy is spent on heating it.