Russian baths are associated with wet steam and a wood stove. And where the stove is heated, there is always a chimney. Caring for it includes periodic cleaning. If you don’t do this, then the heating of the bathhouse will get worse and worse every year. The thrust will simply decrease, and this will reduce efficiency. Sooner or later, everyone wonders how to clean a pipe in a bathhouse. We will tell you how to clean effectively, without extra costs.

When the combustion temperature of wood exceeds 700 ° C, oxidation of carbon and hydrogen elements occurs. This leads to the formation of oxide, carbon dioxide and water vapor. The higher the temperature in the fireplace and heat exchanger, the more likely it is to burn these gases. The efficiency of combustion of gases can be increased by applying heated secondary air to the top of the furnace and appropriately shaping the furnace to cause vortex movement of the combustion gases.

Traditional methods of cleaning a chimney

The combustion efficiency of a properly built rocket can range from 75 to 95%, depending on the design of the furnace, the heater and proper operation of the furnace. For comparison, the combustion efficiency of gases in simple open fireplaces is only 10%. In addition to the rocket stove, combustion efficiency of 80% is also achieved by modern stoves, boilers and fireplaces of a decent standard with regulation of primary and secondary air flow. High efficiency of more than 90% is achieved by advanced boilers with full control independent sources of primary and secondary air, so that they can be supplied at different combustion phases, respectively.

How to clean a pipe in a bathhouse with a special brush.

Various types of bath chimney blockage

Not everyone thinks about what consequences, other than a violation of draft, can result from blockages in the chimney of a bathhouse. Meanwhile, a tenth of fires occur for this reason. Cleaning the oven is only a small part of the entire prevention. And the chimney gets clogged much more often than owners think.

Thus, the rocket boiler is a relatively simple and easy to transport design that provides the most efficient modern technologies combustion when burning gases. Missile fire protocols are Various types simple earthly ovens with proper hollow ducts that served primarily for cooking. Archaeological finds and ethnological research confirms the use of such stoves in many primary cultures, both historically and today.

This fireplace was called a rocket. In the near future, these stoves became increasingly familiar and used in third world countries, replacing older, inefficient stoves. This book has become an inspiration for many people to create their own rocket boilers.

There are several reasons for a blocked chimney in a bathhouse, the most common are:

- Soot and soot.

- Condensate.

- Various foreign objects.

Each of them causes trouble and requires its own cleaning methods.

Soot and soot in the pipe

Soot and soot clog the pipe and the draft in the furnace decreases.

Soot and soot clog the pipe and the draft in the furnace decreases. Soot and soot accumulate inside the structure in a thick layer; over a year it can reach 1–2 cm. Such overgrowth depends on what kind of fuel is used for kindling. So, if the stove is heated with wood, wood briquettes, or coal, then there will be minimal soot. But in sauna stove They burn not only wood, but also household waste, which emit a large amount of soot. Coniferous firewood behaves the same way; when burned, the resin produces soot in large quantities.

The designer whose name must be mentioned in particular is Pieter Van der Berg, a retired Dutch engineer who has inevitably contributed to the development and optimization of the horizontal combustion furnace and its connection to the heater over the past few years.

A brief description of the construction of Pieter Van der Berg's latest furnace, with photographs, is included at the end of this work. When creating a rocket launcher, you need materials from three main groups. Insulating and heat-resistant materials will primarily consist of insulating the hearth and heat exchanger so that it is as hot as possible, which promotes high gas combustion efficiency. In addition, we will also insulate the furnace foundation to prevent heat from escaping to the ground and exterior walls of the building if the furnace sticks to it. Materials that store heat and release it slowly will be thermal mass - this is often a sponge, but thermal mass can take any shape. Materials resistant to high temperatures from which we will build part of the oven. . The rocket boiler in the heating version consists of three main construction sites: combustion, exhaust and accumulation.

There are special briquettes on sale with chemicals, which, when burned, destroy soot. They are simply lit in the stove and after 1–2 days the dirt itself falls into the firebox. It won't be difficult to clean it out from there. But it is not recommended to use such products in baths, since chemicals enter the premises and can negatively affect the health of steamers.

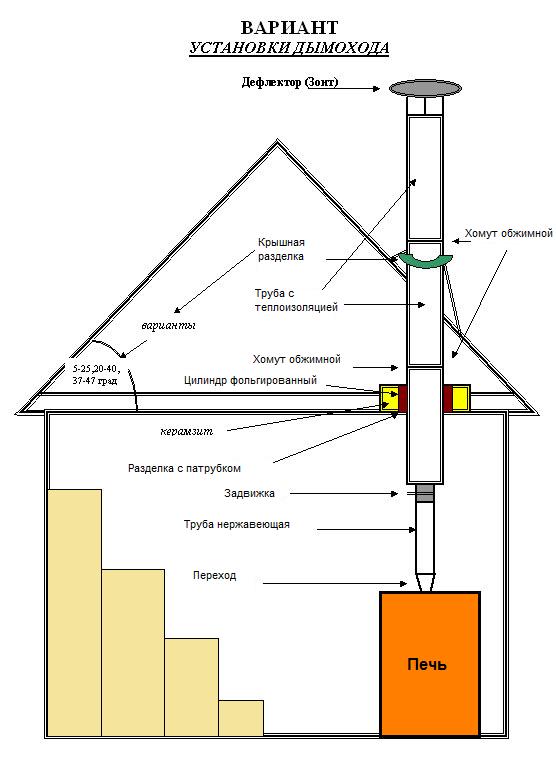

Exhaust design

The chimney design consists of two components: 1 - an inverted barrel that supplies flue gas downwards. Well, a standard industrial 200 liter barrel of oil is good for this role. Before installation, it must burn well to avoid the release of unpleasant fumes during the first days of smoking in the oven. 2 - Exhaust pipe system placed in a mold. These can be ordinary, cheapest tubes - the so-called. steamships. Since they will be covered with a large mass of clay, even if the holes are burned in them for a while, the clay will seal and maintain the shape of the channel.

To clean the bath pipe from soot, it is easier to use a special brush or brush. They are hung on a weight and lowered into the pipe. Craftsmen suggest using cut pieces for cleaning. plastic bottles and other devices. But you can use these if the pipe has a perfectly flat and smooth inner surface.

Thermal mass

The heating bench of the furnace should be heavy, compact, made of clay, stones, debris, etc. The clay used to assemble the bench must be raw, without straw or sand additives. Because the addition of straw and sand increases the insulation of the clay, they are not specified for the thermal bench design. Straw and sand can only be added to the last thin layer of clay plaster - in accordance with the principles of plaster, so that the surface of the bench is smooth and free of cracks.

How to calculate cross-sectional area?

The key unit of measurement used in the design of every furnace - not just rockets - is the cross-sectional area.

The most important design size of the furnace

The key design dimension of a racket stove is the cross-sectional area of the exhaust pipe, which distributes the exhaust gases horizontally within the heating boiler and then pushes it either directly outside or into the chimney.

Condensate in the pipe

Condensation with soot can block the chimney almost completely.

Condensation with soot can block the chimney almost completely. The resin in firewood contains a certain acidity. For each type of wood, the resin content is different. With constant use of the bath, the condensate in the pipes has a small resinous sediment, but with rare use it can reach a thickness of 3 cm.

Other important dimensions and proportions

All major dimensions of internal ducts, passages and turns inside the furnace must always be matched and adjusted to the cross-sectional area of the exhaust pipe. This reduction must be achieved by reducing the height of the rectangular profile, leaving the width unchanged. This compression is called Venturi Venturi and is a very important structural element of the furnace. If this feeder is too high, it can generate its own string, and this can be very annoying. The shorter the better for the combustion of internal combustion combustible gases - the heater. The higher the height of this chimney, the better the combustion of combustion gases and the better.

- Thanks to this, high dullness is maintained, which makes it easier to burn gases.

- Vertical feeder - the lower the feeder, the better.

- Horizontal combustion chamber - should be as short as possible.

It can be difficult to remove such contaminants; due to the increased oiliness, the resinous condensate will simply be smeared on the inner surface during cleaning.

Such a blockage can only be cleared with a special “chimney sweeper log”.

It should be used once a month for prevention, especially if firewood with a high resin content (pine, spruce) is used. If birch is used for kindling, then once every 2–3 months.

What types of contaminants are encountered when cleaning a chimney?

The entire oven can weigh from 500 kg to several tons. The heavier the oven, the stronger the foundation will be. It can be built from large flat stones and clay, bricks or it can be poured with reinforced concrete. If we build both the stove and chimney near the stove, the stove and chimney must stand on the same foundation.

This good idea- install insulation between the oven and the foundation. One old chimney that was built from baking ovens told me that 30 cm of glass paneling was used to insulate such ovens from the ground. In my opinion, the rocket center does not need such a thick layer of insulation. Of course, however, insulating the bottom will have a positive effect on the temperature inside the stove and increase the combustion efficiency of the gases.

Foreign objects in the pipe

Black smoke from the chimney is the first sign of a clogged chimney.

Black smoke from the chimney is the first sign of a clogged chimney. The entry of a foreign object into the chimney is immediately noticeable. The smoke stops being drawn out and goes back into the bathhouse. With such a firebox you can easily get carbon monoxide poisoning. A foreign object may be a brick from a pipe masonry, a bird's nest that has fallen by the wind from the branches of nearby trees.

The figure shows the source of a 15 cm rocket. To build such a stove, we need either 56 bricks or a minimum of 32 bricks. Considering fire resistance, bricks are divided into three categories. For brickwork, only two types of bricks are used: clay-filled and fireclay.

If you are planning to build a kiln using fireclay bricks and regular bricks, it is important to remember that the thermal coefficients of the two types of bricks are very different - the heaters change and stretch differently. Therefore, it is necessary to avoid combining fireclay walls and fireclay bricks and welds made of ordinary bricks. Varied heating and uneven stretching destroy the uniformity of the wall. Therefore, one type of brick should not touch another.

Getting rid of such a blockage is the most difficult. You can try using a long pole or stick to push the object inside. A hook is made of a nail at the end of the stick, so you can try to hook the object if it is not a brick.

Telescopic brushes are available for sale; the handle extends along the entire length of the pipe. You can try to push the object to her. If none of the methods brings results, the pipe will have to be dismantled.

Brick burning brick brick

Use a special fireclay mortar for fireplaces. - Buy in construction stores. The thickness of the seam should not exceed 3 mm. Before mixing, soak the clay for at least one night. Later diluted with water, mixed well and beaten. There cannot be any pieces in the resulting mass of clay. Therefore, the mass is distilled through a 1.5 mm sieve. The solution compresses and mixes well. There can be no lumps in a properly prepared mortar; the mortar does not stick after pressing the brick and is slightly squeezed out of the seam.

Traditional methods of cleaning pipes

Problems with cleaning pipes arose not only in modern baths. Our grandfathers also fought blockages in their own ways. Some of them have shown themselves to be good and are still used today. Moreover, it is better to clean pipes in a bathhouse without chemicals. Choosing a method for yourself must be based on the following factors:

Notes on channel solution

Before starting masonry work, the bricks should be soaked with water for several minutes to prevent rapid penetration of the capillary brick mortar. The optimal wall thickness of the furnace wall is 3-8 mm. When building ductwork with clay-treated bricks, thoroughly wipe the clay joints with a damp hand. By smoothing the welds, the more soot sticks to them, and the easier it comes off when cleaning stoves.

Closing the furnace after hardening

When the furnace is already warming up and goes out, the air will continue to have a natural tendency to push through the furnace. And the flowing air releases heat from the furnace. Therefore, when the furnace goes out completely, it is important to close the fuel tank tightly. Then we will be sure that air is no longer flowing through the oven.

- Metal or brick structure. Cleaning a simple metal sandwich pipe is easier because the inside is smooth and even. Brick is more difficult to clean.

- Design, with bends or straight (straight is easy to clean with a brush, a chimney with bends is more difficult).

- How complicated is the blockage?

- Pipe diameter.

How to determine when it's time for cleaning

A weight with a brush will clear any blockage well. mechanically.

A weight with a brush will clear any blockage well. mechanically.

There are several ways to determine whether it is time to clean the pipe. The most common one is to use a kettlebell. It is selected according to the diameter of the pipe. On the rope, lowering the weight into the pipe, watch how it passes: freely or not. If the weight gets stuck, then it’s time to clean it long ago. In this way, by throwing and lifting the weight, you can clean the pipe from large contaminants.

Exhaust length

This is confirmed by many years of experience based on dozens of tragic events involving people. The length of the exhaust system depends primarily on whether the stove is connected to chimney or not. Because if it is connected to a chimney, it must be shorter so that the temperature of the flue gases entering the chimney is warm enough to allow it to break through the chimney and initiate a chimney draft. If we do not connect to the chimney, in the case of a 15 cm stove we can safely place a 6-9 meter horizontal pipe on the bench.

Second folk way watch the smoke during kindling. If it is colorless or whitish, then the chimney is clean. The appearance of clouds of soot and black smoke should alert the owner and become a reason to begin cleaning activities.

Of course, with the exception of damp and pine firewood, since when the resin burns, the smoke also has a dark color.

A longer length will no longer give us any effect, because the smoke at 9 meters should be completely cold. In the case of a 20 cm stove that is not connected to the chimney, we can insert 9 to 12 meters of pipe into the bench. These cleaners need to be larger - at least as much as the bends along the horizontal route in the heat bench. Through cleaning, a special cleaning brush for the furnace channels is introduced, and the soot is cleaned. Special doors are often installed in place of the vacuum cleaner, but cleaners can also be filled with ordinary brick or stone.

To light a bathhouse, it is generally better to use dry logs that have lain under a canopy for at least 1-2 months. Linden and birch firewood is preferable, since there is practically no soot from them.

Cleaning with water

You can try to clean the chimney with plain water; this method is ineffective for severe blockages.

You can try to clean the chimney with plain water; this method is ineffective for severe blockages. If the structure is iron, with a small diameter, then in winter you can shove a lump of snow with a diameter of 9–10 cm into it. It will melt and wash out the pipe, and gradually sliding down, scrape off the digging with sharp pieces of ice. But after this, the stove must be heated, so the pipe will dry out and not freeze from the inside. And on metal, without drying, rust can form inside, this will shorten its service life.

In the same way, 1–2 liters of warm water are poured into the pipe before kindling. This is done gradually along the walls. With such cleaning, black smoke clouds of soot will appear from the chimney during combustion.

Factory expensive oven models have special system ceilings You should not throw snow into such a structure, but it will be easier to spill water. A container is placed inside the furnace firebox where the dirt and soot will drain and fall off, only then water is spilled.

Cleaning with aspen wood

Cleaning a chimney with aspen is the oldest and most proven method.

Cleaning a chimney with aspen is the oldest and most proven method. Our grandfathers noticed that when aspen wood burns, pieces of soot and soot that fall off the chimney appear in the stove. This phenomenon was later explained by the composition of aspen smoke, which can break down deposits on pipes. After such cleaning, a layer of dirt will fall off inside the stove in small pieces within 1–2 days.

Perform cleaning as follows:

The stove is heated as for a regular wash and at the very end, aspen firewood is thrown in 1-2 times. They won't produce much heat, but they will clean the pipe. Later, the procedure can be repeated as prophylaxis 1-2 times a month.

Before cleaning, a special device is attached to the top - a spark arrester. You can make it from an old tin can: the walls are cut out and rolled into a cone. The cone is attached to the pipe at a distance of 5–7 cm from above. Sparks during combustion will fall inside the device and the possibility of fire is reduced.

Sellers often offer the chemical Kominichek or Stumpfyre as cleaners. But it is unacceptable to use the compositions in the bath!

Whether or not to clean the bathhouse pipe is not a question. It is necessary to clean systematically. Once a month, do preventive maintenance using a chimney sweep or aspen firewood. This is the only way the bathhouse will serve its owner for a long time, and the chimney will not burn out ahead of schedule. In addition to all of the above, it will be difficult to get burned in a properly functioning bathhouse. And the video suggested in this article will help you choose a convenient cleaning method.

All owners of a Russian bath from time to time are faced with the question of how to clean the chimney.

To prevent chimney contamination, you can use dry cleaning. It also copes with a not very thick layer of soot.

During operation, the pipe passage becomes clogged, draft decreases, which leads to a decrease in the efficiency of the room's furnace.

In addition, the risk of fire increases. How you can clean a bath chimney will be discussed below.

Types of pollution

For safety reasons and to ensure high-quality heating of the bathhouse, it is advisable to establish a cleaning schedule and clean the stove and chimney at least once a year. During the operation of this building, the following types of blockages may occur:

- Foreign object. It is the most difficult contamination. It could be a bird's nest, a fallen piece of brick, etc. It takes up a lot of space in chimney, thereby blocking the free exit of smoke to the outside.

- Accumulated soot. The more often the sauna is heated, the thicker its layer. The amount of soot depends on what kind of fuel is used. There will be almost no soot when using fuel briquettes, firewood, and charcoal. Its rapid formation is facilitated by the combustion of household waste.

- Condensate. Its formation is facilitated by the irregularity of the firebox. It is a weak acidic solution, which over time can cause destruction. Resinous deposits settle on the walls.

Methods for cleaning a chimney

The main methods for cleaning a sauna chimney include:

- mechanical;

- chemical.

In order to clean the chimney mechanically, you will need the following set of tools:

- rope;

- ball (weight);

- brush-ruff (can be replaced with a more advanced cleaning rod, which is a brush on a thin metal cable).

Before starting the cleaning procedure, it is necessary to check the chimney and the integrity of its channels. If there are foreign objects in the pipe, they should be pushed with a pole from top to bottom. The effectiveness of work on removing blockages is largely determined by the right choice brush shapes. Therefore, when purchasing it, you need to give preference to options that are more consistent with the dimensions of the pipe.

Modern chimney sweep tools, compared to classic and slightly outdated sets, allow for higher quality and more comfortable cleaning work for the performer. The special brush has a handle that adjusts its length and facilitates movement inside the pipe. To carry out cleaning work, you need to remove the first link of the handle from the set and screw the brush to it. This device cleans the chimney using gentle up and down movements. The brush needs to be installed and moved along the pipe, gradually increasing the brush links. The same technology is used to work when using a brush attached together with a weight to a rope.

Chimney cleaning is required once a year. If this is not carried out, the draft will decrease and the bath will take longer to warm up.

To protect yourself from soot particles, the chimney sweep needs to use gloves, goggles and a respirator. The handle of the brush should be wrapped in a rag and placed close to the opening of the firebox. As you work, you need to try not to rotate the handle too much so that it does not unscrew, leaving the brush in the pipe passage.

When cleaning the chimney, specialists can use a special high-power vacuum cleaner that sucks out soot through the firebox opening. However, this method will be effective only for small deposits.

When using the chemical method of cleaning a bath chimney, various preparations are used, produced by manufacturers in both powder and liquid form. However, the “log-chimney sweep” became the most popular. It needs to be put in the stove and set on fire. The smoke released during combustion will react with the soot and make it pliable. In a couple of days, the contents of the chimney will fall into the firebox and all that remains is to remove it from there. The advantage of this method is not only ease of execution, but also its absolute safety due to the absence of toxic substances.

Taking into account the information described above, everyone will be able to choose the most suitable method for removing contaminants from the sauna chimney. It should be remembered that systematic cleaning of the pipe is the key to the longevity of the bathhouse and fire safety.