One of the most important aspects is to determine the requirements that are relevant to a particular situation. The safe operation of the gas boiler and its maximum performance depend on this.

All indicators should be divided into two categories. The first includes the characteristics of the chimney itself, the properties of the material used and similar nuances. The second category looks at building codes that can narrow the range of options available to choose from. Correlating the two groups of indicators with each other yields the optimal result.

Signs of a quality chimney

First of all, let's look at the signs of a quality product. Nice chimney for a gas boiler must meet the following criteria:

- withstand high temperatures;

- do not be afraid of moisture;

- resist chemical attack;

- provide traction;

- prevent soot from accumulating, especially in hard-to-reach places.

How to make a brick chimney with your own hands? Many owners ask this question. stove heating. This process is not very easy and labor-intensive, but it saves money. Let's take a closer look.

High temperature is the result of heating the air and releasing hot gases after fuel combustion. When smoke and gases are removed, the surface of the pipe heats up. If it is not designed to withstand high temperatures, cracks may appear in the chimney, which leads to combustion products entering the room.

When a temperature difference occurs, condensation may form on the pipes. For some materials, moisture accumulation leads to their destruction. In addition, for metal parts this is fraught with the development of corrosion.

Important: In some cases, special traps and drains are provided to collect condensate.

In addition, one should take into account the formation of aggressive chemical compounds, which also have a destructive effect. This primarily concerns sulfur, which is released when fuel is burned. For gas boilers, this problem does not have a strong impact.

Building codes

Other requirements relate more to construction concepts. The presence of good traction is determined by the presence of natural or forced supercharging. Only some chimneys are designed for both methods of operation.

Regarding soot accumulation, for gas equipment this problem is also relevant. It is important to prevent it from igniting and excessive accumulation, otherwise carbon monoxide will enter the room.

When arranging a chimney, it is important to consider a number of other points:

- It is not recommended to make a tortuous channel; the number of elbows should not exceed three;

- the pipe diameter cannot be less than the cross-section of the boiler pipe;

- the inside of the pipe should be as smooth as possible;

- the channel must be completely sealed.

Video: construction and installation of a chimney for a gas boiler

It is recommended to install an automatic draft limiter on the boiler in advance so as not to manually control the position of the dampers. There is also a hatch for cleaning the system from burning. The optimal channel shape is cylindrical, as it provides the best removal of excess combustion and also does not allow large amounts of soot to accumulate, as happens with the corners of rectangular outlets.

Important: Since the pipe heats up during operation of the system, care must be taken to keep it away from flammable and flammable objects.

Types of structures

Based on the indicators described above, you should also select the most suitable type of structure. There are many types of chimneys. They differ in the materials used and arrangement methods, location and other structural nuances.

In general, almost any option is suitable for gas boilers, but some equipment features impose their own limitations.

Brick chimney

Let's look at the most popular types of combustion product removal systems. The traditional type is a brick chimney. They are used in private homes when equipping all types of boilers, fireplaces and stoves.

In order for the building to withstand the load, it is necessary to consider the foundation for the chimney. That is why the entire system must be provided for during the design of the house itself.

Today, such systems are used mainly for solid fuel boilers, and gas ones are equipped with lighter and more practical models. There is a rational explanation for this:

- refractory bricks cost a lot and require skills to lay them well;

- there is a significant load on the load-bearing elements of the building;

- soot easily accumulates inside the brick channel;

- brick is more vulnerable to condensation and sulfuric acid.

There is a way to solve this problem, which is to supplement the brick channel with other materials: steel and ceramics.

Ceramic pipes are the best option for any type of equipment. This material has many advantages:

- heat resistant;

- not afraid of moisture;

- resistant to chemical attack;

- durable;

- the smooth surface prevents soot from settling.

Ceramic gas chimney is selected for operating mode at a temperature of 400-450 degrees and is supplemented with condensate traps.

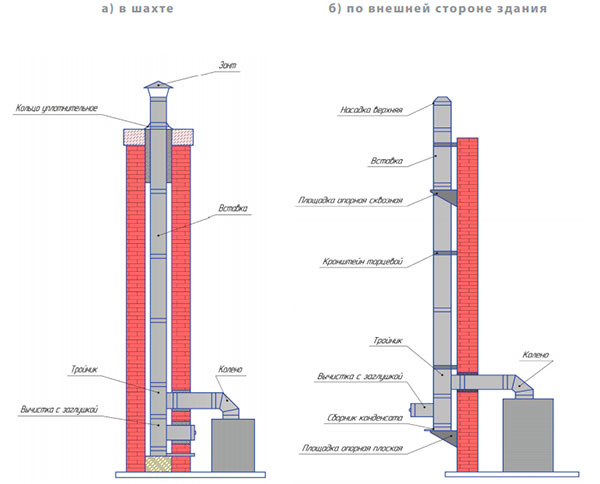

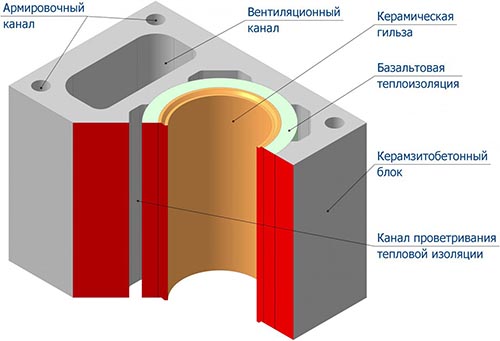

The ceramic pipe is complemented by a layer of insulation. In order to prevent this entire “pie” from accumulating moisture, ventilation channels must be equipped on its sides. That is why special concrete or expanded clay modular blocks are ideal for installing the system. They may also have holes for communications, structural reinforcement and purge.

Advice: If you plan to install outside the shaft, then it is more advisable to consider the option of combining a ceramic sleeve and a steel body. This product has an attractive appearance and will not spoil the decoration of the home.

Of course, the cost of such products is rather high, but these costs are fully justified in the future.

Steel

Also a popular option for modern homes is a steel chimney. It is used both independently and in combination with other materials. For the ceramic model, the steel pipe serves as a protective and at the same time decorative shell. For the brick version, this is a way to reconstruct a damaged channel. Metal pipe simply insert into the shaft and fix it in the desired position.

It is also an ideal chimney for a wall-mounted gas boiler. It is much easier to remove a metal channel from the equipment to the street, since it can be assembled from separate modules. It can also be laid outside the walls, both indoors and outside the house. Glossy metallic shine will complement a modern interior, especially if we talk about a style such as hi-tech.

The steel used to produce such products must be of sufficient thickness to withstand negative impact condensation, heat and gases. In this regard, the cost of good models exceeds the price of previous samples. Cheap models won't last you longer than 5 years, so it's not worth saving on this.

Design features

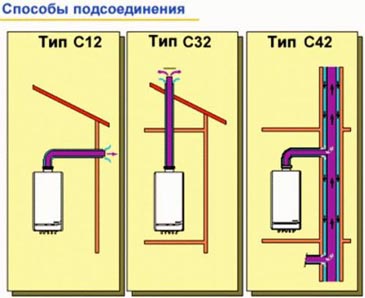

Separately, it is worth highlighting the design principles different types chimneys. There are three types of pipe connection and removal:

- Horizontal. Mainly used for boilers with a closed combustion chamber. The pipe goes out to the street through the wall. Coaxial models in apartments and private houses are arranged according to this principle.

- Vertical. This is the traditional option when the pipe directly goes up through the roof.

- Combined. We are mainly talking about general ventilation, which is important for apartment buildings. In this case, the chimney consists of two parts: horizontal from the boiler to the shaft and vertical in the form of a common outlet.

Sandwich pipes also need to be highlighted separately. These are mainly steel samples. They consist of an inner and outer tube, and the space between them is filled with a layer of insulation. Such models are produced in the form of modules. This is the best option for assembling an outlet outside the wall. In addition, the insulation partially protects the pipe from the formation of condensation.

To ensure good draft in the boiler and uniform combustion, it is necessary to provide access fresh air. For this purpose, a special type of chimney with additional ventilation ducts is used. This type includes, first of all, the coaxial type of structures.

Its peculiarity is that it consists of two main parts: an outlet for smoke and gases, as well as an inlet channel. The inner steel pipe releases the smoke, while the outer part of the system introduces air. This is the so-called “pipe in pipe” system. It is thanks to this that air from the street enters the boiler and supports its combustion. This is an excellent compact option, suitable for indoor installation. However, with temperature changes, there is a risk of condensation forming and freezing in cold weather. As a result, the outlet is blocked and the boiler automatically turns off. Otherwise, carbon monoxide will enter the room.

Selecting the right option

So, which chimneys are best suited for a gas boiler in a private house or apartment? To choose the optimal type of product, you should focus on the following factors:

- Boiler type and power. The brick look is not entirely suitable for gas equipment, so the choice must be made between ceramic and steel outlets, and thin steel will quickly become unusable under heavy load. With a closed combustion chamber, coaxial systems are used.

- Type of construction. In a private house, an outlet is available through the roof or along the outer wall of the building. In an apartment, it is better to use coaxial models. If the boiler is located in the upper part of the house, try to reduce the load on the floors and use lightweight materials, that is, steel.

- Presence of old systems and communications. If the house had a solid fuel boiler, the brick outlet can be adapted for a gas one. For this purpose, ceramic or steel inserts are used.

- Affordable budget. The best option would be ceramics, since it costs less than steel and lasts much longer.

A coaxial chimney is one of the safe, environmentally friendly ways to remove smoke from a room when heating with a gas boiler. It can be of several types. Let's look at the installation system of each of them, as well as the features of baxi smoke exhaust ducts.

Installation begins from bottom to top. It is imperative to provide a window for cleaning the pipe from soot, and also install condensate traps. The pipe itself, if it is not a ready-made sandwich module, is additionally wrapped with insulation.

You cannot use more than three knees. Clamps and clamps are used at each connection to prevent gas leakage. When mounting externally, brackets must be installed, at least one for every 2 meters of pipe.

We wrote earlier and advised you to add the material to your bookmarks.

Important: If a horizontal or combined chimney is installed, to prevent stagnation of gases, it should not be made longer than 1 meter.

Another important point- proximity to other communications. If gas or water pipes or electrical wiring are laid nearby, you must maintain a distance. Do not allow the chimney and all these elements to come into contact with each other.

Steel pipes are equipped with flexible adapters to compensate for thermal deformation of the material. You also need to ensure that no bends occur when tightening the system with brackets.

The correct choice and proper installation of the chimney will ensure maximum output from the gas boiler. In addition, this is a guarantee of your safety, since heating equipment is always associated with certain risks.

From the article you will learn how to install a chimney for a gas boiler in a private house, about external and internal chimneys, about chimney elements, about coaxial chimneys, about the features of a condensing gas boiler that do not use conventional chimneys, about brick chimneys, and about correct installation chimney.

Why do many people choose gas heating these days? Yes, because it is the cheapest type of fuel.

Once you have decided on the choice of a gas boiler, you should also think about removing the “waste” gas from the room. What should a chimney be like for a gas boiler? The Fire Inspectorate has very high requirements for these structures, so approach the work consciously and responsibly.

How to make a chimney for a boiler?

Selecting the overall dimensions of the chimney

The gas boiler chosen for heating a private house must be available to you, only after that you can select the correct chimney for the gas boiler and calculate its dimensions (see Chimney calculation).

The height of the chimney depending on its location relative to the ridge of the house

Attention. If there are extensions above the house or it is planned to build them in the near future, then it is necessary to build a pipe that extends beyond the adjacent building.

Variations with chimney length

By selecting the required diameter and length for the chimney pipe and calculating its usable area, it may turn out that this same area will be less than the internal area of the gas boiler. If you change the pipe diameter to the next one (all pipes are produced in standard diameters), then with the same length you will get an excess chimney area and, accordingly, an excess consumption of material.

What can be done in this situation? Increase the length using a smaller pipe diameter. The table shows the minimum pipe heights. They can be increased, but not decreased.

After calculating the overall dimensions of the chimney pipe and purchasing the necessary building materials, you can begin installation.

Installation of chimneys for gas boilers

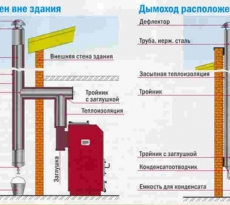

Immediately before starting work, you should determine the location of the chimney. There are 2 accommodation options:

When choosing the location of the chimney, you should understand:

- location inside a private house will provide the structure with the most “comfortable” operating conditions;

- the location behind the walls of a private house requires the presence of insulation to prevent the chimney from freezing; in this case, it is advantageous to use a sandwich pipe (the sandwich pipe has a multi-layer device, in the center of the sandwich pipe there is a layer of insulation).

Of course, the choice of location of the chimney for a gas boiler is yours. Check out the table below to help you make your choice.

Comparative characteristics chimney inside and outside a private house.

How to make a chimney for a boiler?

Installing a chimney for a gas boiler in a private house is not very easy.

Let's look at the basic principles of installing a chimney for a gas boiler.

- It is necessary to correctly assemble all pipe elements.

- In places where the smoke exhaust structure passes through the ceilings or walls of a private house, it is necessary to install special passage elements.

- Insulation of all surfaces in contact with flammable materials.

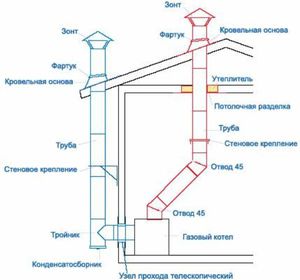

Chimney elements of a floor-standing gas boiler:

- adapter from the gas boiler pipe to the chimney pipe;

- tee with inspection (at the bottom there is a fitting designed to remove condensate);

- main fastenings - bracket and wall clamp;

- bends, they are used at a distance of no more 2 m from the beginning of the chimney, otherwise it becomes possible to reduce the boiler draft;

- feedthrough pipe;

- telescopic pipes;

- special tip having a conical shape

Please note that the tip for chimneys that remove “exhaust” gas must have a conical shape. It is strictly forbidden to install ordinary deflectors and umbrellas. It is allowed not to install the tip at all.

Requirements for the chimney of a floor-standing gas boiler:

- the slope of some sections of the chimney is allowed no more than 30°;

- maximum branch to the side - 1m;

- the smoke exhaust duct device should not have ledges or narrowing of the cross section;

- the maximum number of elbows that a structure can include is 3, the radius of curvature must be greater than the diameter of the pipe;

- at turning points it is necessary to install a hatch for cleaning and eliminating condensation;

- one side of a rectangular chimney should not be 2 times larger (smaller) than the other, i.e. the shape should not be elongated;

- At the bottom of the chimney, an inspection and drip device is required;

- Deflection of chimney elements is not allowed;

- the pipe links are placed on top of each other by at least half the diameter of the pipe;

- Any gaps between pipe joints are not allowed;

- in places where the ceilings (roofs) pass, the pipe should not have joints;

- all elements must be very tightly connected to each other;

- the slope of the pipe towards the gas boiler must be at least 0.01°;

- Roughness in the chimney is not allowed, the inner surface of the chimney elements must be perfectly smooth;

- horizontal sections can have a total length 3m in buildings under construction and no more 6 m in built;

- Below the connection point of the tee, a so-called “pocket” is required, with a length of at least 25 cm with a hatch (this will provide access to the pipe and the ability to clean it);

- distance from the pipe to the structure (walls and ceiling) for flammable materials - 25 cm, non-flammable - 5 cm;

- if the pipe passes through unheated areas of the structure, thermal insulation or installation of a sandwich pipe must be provided;

- when removing “exhaust” gases from utility appliances, dampers (gates) should be provided;

- it is necessary to bring the gate control to an accessible place with fixation of the “open” and “closed” positions;

- If the device has a traction stabilizer, then dampers are not needed.

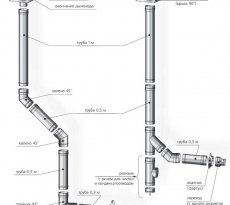

How to properly build a chimney for a gas boiler outside the house?

- We attach a passage element to the pipe coming from the floor-standing gas boiler, which will pass through the wall of a private house.

- After the opening is ready, we take the chimney out. The sandwich pipe section and the hole in the wall must be insulated.

- We attach the tee with revision, put on the plug.

- We extend the sandwich pipe by attaching links, attach it to the wall of the house with brackets, in increments of at least 2 m .

- Having reached the estimated height of the chimney, we attach a cone-shaped tip.

- We reinforce all sandwich pipe joints with clamps, which must be tightened with bolts or wire.

- It is advisable to paint the pipe with heat-resistant paint, which will protect the material from corrosion.

If you do not want to use sandwich pipes as a building material for the chimney, then do not forget about the thermal insulation of the structure.

Installation of chimneys for boilers in the house

Let's start with the preparatory work:

- We mark the holes for the chimney in the ceilings and roof.

- Be sure to check the marked marks several times with the dimensions of the passage pipe. Cut out the required opening for the pipe.

Let's start installing the pipe:

- A pipe comes from the boiler. We connect the adapter to it.

- Next, we attach the tee and revision (for cleaning the pipes), attach the steel sheet and install the main bracket.

- We extend the pipe, if necessary, use the so-called elbows.

- When passing through ceilings, we use a special pipe.

- We put a galvanized steel sheet on the pipe with a hole slightly larger than the diameter of the pipe. We attach the sheet to the ceiling on both sides.

- We reinforce all joints with clamps secured with wire or bolts.

- The chimney is secured using wall clamps (each 2 m) and brackets (each 4 m).

- We complete the design with a special cone-shaped tip, which will protect the chimney from precipitation and wind blowing.

Insulation of chimney elements

All contacting parts of the chimney and flammable structure must be insulated. To do this, the passage pipe must be covered on all sides with a foil-coated basalt mat with fire-resistant mastic. Mineral wool insulation can be laid around the perimeter of the opening in the ceiling.

Upon completion of installation work, be sure to check the tightness of all seams in the structure. Make an ordinary soap solution and apply it to all chimney seams. If, after connecting a gas boiler to the chimney, you see bubbles, this indicates a leak.

Brick chimney for gas boilers

A chimney can be built not only from steel (certain grades), but also from brick. Or rather, the chimney will be located in brickwork, i.e. the chimney pipe can be metal, asbestos or ceramic. Visually, it will seem that the chimney is made of brick.

Why is it undesirable to build a chimney made of brick?

The fact is that brick is a fairly porous material that does not hold heat well enough. When gas burns, water vapor with various impurities is formed, which, in fact, must be removed from the room, and the construction of a brick chimney will contribute to the formation of condensation.

Chimney for condensing boilers

In general, the chimney of a condensing boiler differs little from the chimney of a conventional boiler, but there are some peculiarities. The chimney of a condensing boiler must be made of acid-resistant materials to protect against corrosion.

It is important that the condensing boiler chimney is sloping to the side heating unit. It is necessary that the condensate flows back, but that precipitation does not enter the unit. Raindrops can damage the condensing boiler.

Chimney for wall-mounted gas boilers

The most optimal building material for wall chimney- double-circuit pipes.

A coaxial chimney consists of 2 pipes, which are inserted one into the other (see Coaxial chimneys). This chimney resembles sandwich-type pipes, but without insulation between the pipes. This ensures the removal of “exhaust” gas and the flow of fresh air through the gap between the pipes.

Installation of such a chimney is quite simple. We attach a flow pipe to the pipe from the boiler and take the pipe outside. The distance from the chimney to the ground must be at least 2 m. When placing the chimney under a window, at least 1 m from the window to the ground level.

Gas boilers without chimneys

Gas boilers without a chimney are the last word in technical progress in this direction. The operation of the system as a whole differs from a conventional gas boiler. Let's not go deeper into this issue. The best thing about this system is that there is no need for a traditional chimney.

In any heating system it is necessary to remove combustion products outside the room. The difference is in the chimneys. In the new system, the chimney can be made of PVC pipes(the temperature of the “exhaust” gases is relatively low) with any number of turns, it no longer has to be strictly vertical.

Temperature The boiler operation can be anything. The unit runs on both natural and liquefied gas. In case of any problem it turns off automatically.

The information you have gathered will help you when installing a chimney with your own hands. If you want to use the services of professionals, then you will be savvy in the topic of chimneys for gas boilers. This will allow you to independently carry out supervision of the work being carried out.

After choosing a place to install a gas boiler, you need to take care of installing a chimney to remove smoke and exhaust carbon monoxide. What material should it be made of? If several decades ago chimneys were made exclusively of brick, modern heating technology imposes completely different rules on the construction of chimneys. Not only that, it must comply with current building codes.

Types of chimneys for a gas boiler

The chimney is designed to remove exhaust gases into the atmosphere. The work is based on the principle of natural traction. Depending on the conditions of use, chimneys have many design features. The performance of a gas boiler depends on what material the chimney is made of.

A prerequisite for using a gas boiler is the installation of a ventilation system

Brick chimney. They are rarely used, since modern gas boilers have a high efficiency. The temperature of the gas emanating from the boiler is low (about 100 degrees), and when moving up the chimney it cools and condenses on the walls, since there is steam in the outgoing gases. Therefore, it is very difficult to warm up a brick chimney to the dew point transition temperature. What to do if you already have a chimney from old stove in a good condition? In order not to dismantle an existing chimney, you can use:

- lining, that is, insert pipes from inside of stainless steel, and fill the space between the chimney wall and the pipe with non-flammable heat insulator. Perlite, foam glass or expanded clay are suitable as a heat insulator. This procedure will insulate the chimney and significantly reduce the amount of condensate formed;

Sleeving

- line the channel. Lining is performed if the existing chimney is of non-standard size or has a crooked channel. This method is more expensive than installing steel pipes. A special elastic polymer liner is placed in the chimney duct. Then steam is pumped from below by a generator, a reaction occurs and the filler expands, taking on the shape of a channel.

Sandwich made of stainless steel pipes. Widespread technology. Perhaps one of the best designs for arranging the chimney of a gas boiler. Manufacturers offer ready-made modules from which chimneys of various sizes and configurations are assembled. Structurally, it is a pipe that is contained in a corrosion-resistant steel pipe that is resistant to acids. The distance between the pipes is filled, as a rule, with heat-resistant basalt wool.

Coaxial chimney. Has an attractive appearance. The design resembles a recuperator device, when combustion products are discharged into the atmosphere through an internal pipe, and heated air is supplied to the boiler furnace through an external pipe. Such a chimney device does not require additional installation of a ventilation system, since the air from the room is not used for combustion by the boiler, and accordingly this affects the comfort inside the room. A coaxial chimney increases the efficiency of the boiler.

Coaxial pipe components

Ceramic chimney made from ready-made modules. Their main trump card is fire resistance and durability. They do not collapse even at a combustion temperature of 1200 degrees C. The manufacturer guarantees their reliable operation for 30 years, confirmed by European certificates. Their only drawback is their unpresentable appearance.

Main elements of chimneys:

- pipes: chimney and extension;

- tees;

- knee;

- condensate outlet;

- draft regulators;

- ending elements.

Advice. Condensation also settles on the inner surface of asbestos-cement and galvanized steel pipes, which is why they are not used when installing a chimney.

Installation of a chimney system

Chimneys of any design must necessarily comply with the requirements of regulatory documents SNiP and DBN.

- the chimney must be perpendicular to the foundation. A small tolerance from the perpendicular to the side is possible up to 1 m per 300;

Chimney installation

- inclined sections in cross-sectional area cannot be smaller vertical sections;

- The surface of the chimney channels from the inside must be smooth-walled. The composition of the materials from which they are made must ensure their tightness and fire resistance;

- the channel cross-section is always calculated based on the boiler power;

- At the bottom of the vertical chimney, a tee with a plug must be installed to drain condensation;

- an inspection must be installed on the horizontal part of the pipe.

Height of chimneys according to standards

Correct placement of the chimney on the roof outside the wind pressure zone at the correct height relative to the roof ridge guarantees good draft and uninterrupted operation of the unit.

Standards for placing chimney pipes

Standards for placing the chimney in height:

- The chimney must be located at least 50 cm above the roof ridge, provided that the chimney itself is located at a distance of one and a half meters from the ridge.

- If the pipe is located at a distance of one and a half to three meters from the roof ridge, then the top of the pipe should be level with the roof ridge or higher.

- Above flat roof the chimney must rise at least 1 m.

- Additional strengthening of the gas outlet will be required if it is more than 1.8 m higher than the roof.

Advice. The ideal shape of a gas outlet for a heating gas boiler is an oval. In square pipes, carbon monoxide creates turbulence in the corners of the flue structure, as the gases tend upward in a spiral, which leads to a deterioration in draft.

Installation of a chimney according to the rules

Based on where the gas boiler will be located relative to the house, the chimney installation is carried out in two ways:

Indoors. Installing such a system is quite troublesome, and it is also necessary to strictly comply with fire safety requirements, because such a chimney has an increased risk of ignition or carbon monoxide leaking into the room. If all the rooms through which the chimney pipes pass are heated, then only the pipe located on the roof will need insulation. Please note that such a chimney is difficult to repair.

Coaxial pipe installation options

If you decide to install a chimney for a heating gas boiler yourself, then you first need to apply marks for drilling holes for the flue pipe in the ceiling and roof. Then double-check everything again, as they say: “measure seven times, cut once.” Cut out the opening. Now, let’s actually assemble the chimney:

- connect the heating boiler pipe to the adapter;

- Now you need to connect the tee and revision. After this, a sheet of steel is attached and the main holder is secured;

- we extend the gas outlet pipe from the bottom up, if necessary, use elbows;

- a special pipe is used in the place where the chimney crosses the floor of the house;

- Next, you need to throw a galvanized sheet over the chimney with a hole made in it, which is larger than the diameter of the chimney, and secure this sheet at the top and bottom of the ceiling;

- all places where gas outlet structures are joined must be additionally reinforced with clamps;

- We put a cap on the very top of the chimney - it will protect the chimney from bad weather.

Internal and external placement of the chimney

Outside. Due to the uniformity of the constituent elements of the chimney, it is easy to install and therefore easy to repair. Such a chimney requires thermal insulation along its entire length. If you are installing a chimney on the outside of the house, then the procedure is as follows:

- We mark the places for drilling openings and double-check. Then we thread the system passage through the drilled opening, one end of which is hermetically connected to the boiler pipe. The area that penetrates the wall is thermally insulated;

- we attach the revision and tee, then connect the plug;

- We install the flue elements from the bottom up. Don’t forget to attach the holders to the surface of the house;

- We reinforce all joints with clamps;

- Now you need to attach thermal insulation along the entire length of the chimney; this does not need to be done if you used a sandwich pipe.

Chimney installation methods

When installing a chimney, remember:

- all structural elements must be assembled correctly, gaps are unacceptable, and deflection of elements is also unacceptable;

- in places where the chimney crosses the structure of the house, it is necessary to install passage elements;

- The boiler and chimney are connected by applying heat-resistant sealant to the joints.

Advice. Thermal insulation of the chimney is performed with mineral wool, which is wrapped on top with foil or a sheet of galvanized steel. But there are ready-made products made from mineral materials on sale; you only need to measure the diameter and length of the pipe.

Gas boilers without traditional chimneys

Gas heating boilers without traditional chimneys are a solution for apartments. These are units with a closed combustion chamber, they have a built-in special system to remove carbon monoxide. These boilers do not need a chimney with natural draft, because a special turbine in forced mode removes exhaust gases from the firebox. The gas exhaust system for such gas boilers can be used from polyvinyl chloride with any number of turns, and it is not necessary to maintain a vertical position. This type of chimney is designed as a coaxial type, it is led out through a hole in the wall of the apartment, and is aesthetically attractive.

Standards for installing a chimney relative to the building facade

When choosing a chimney for a gas heating boiler, be guided by the parameters of your device and the requirements for the installation of chimneys. This will guarantee your safety, as well as the uninterrupted operation of your gas equipment.

Which chimney to choose for a gas boiler: video

Chimney for a gas boiler: photo

A properly installed chimney is the most important part of a heating system. That is why gas workers have reasonable requirements for this device. Competently arranged system allows not only the gas boiler to operate efficiently, but also ensures the safety of the residents of a private house. The operation of such gas appliances occurs without visible smoke, but this does not at all guarantee that carbon monoxide will not accumulate. It is very dangerous because it has a negative effect on the human body.

Residents of private houses need to understand the design of a chimney for a gas boiler in order to operate it correctly. And those who are just planning to install a gas heating device should be aware of what types of chimneys exist and what requirements are placed on them.

Types of chimneys for a gas boiler

Brick construction

Brick pipes for gas boilers began to be installed at a time when no other materials were available. Currently, some homeowners are building them, although Such a pipe is complex in design and labor-intensive to install. In addition, building such a brick system takes quite a long time and is expensive.

Brick pipes for gas boilers began to be installed at a time when no other materials were available. Currently, some homeowners are building them, although Such a pipe is complex in design and labor-intensive to install. In addition, building such a brick system takes quite a long time and is expensive.

Such a brick chimney in its own way technical specifications significantly inferior to more modern systems, because its inner surface is very often overgrown with soot, as a result of which the removal of fuel combustion waste is slowed down.

Ceramic construction

Such a system already has many more positive qualities. They are especially noticeable in cases where installation is done by hand. The ceramic chimney is very reliable and quite simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive aspects, this design is not in great demand.

Such a system already has many more positive qualities. They are especially noticeable in cases where installation is done by hand. The ceramic chimney is very reliable and quite simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive aspects, this design is not in great demand.

Coaxial design

This system has significant differences from other designs in all respects. It has a neat appearance, and the shape of the pipe compares favorably with all other pipes and is led out through the wall.

This system has significant differences from other designs in all respects. It has a neat appearance, and the shape of the pipe compares favorably with all other pipes and is led out through the wall.

Although such a chimney is small in size, it works very efficiently due to its structure and special coating on the inner walls. Condensation never forms inside it, and this is very important for heating systems that run on gas fuel.

Stainless steel sandwich construction

This system is considered the most popular because it has a number of significant advantages over other designs. Such chimneys come in various modifications, and this is important. They have a large number of tees, various transitions and other parts that are made at different angles. Thanks to this, you can assemble a structure of any complexity.

This system is considered the most popular because it has a number of significant advantages over other designs. Such chimneys come in various modifications, and this is important. They have a large number of tees, various transitions and other parts that are made at different angles. Thanks to this, you can assemble a structure of any complexity.

The stainless steel sandwich chimney consists of three layers. The middle layer is heat-insulating, made of mineral wool. The thickness of the insulation layer is 5–10 cm and it depends on the location where the chimney pipe will pass and the average temperature in winter. A correctly selected pipe will not contain condensate, on which the proper operation of the entire system depends.

The stainless steel construction has a perfectly smooth inner surface, which makes it easy to remove combustion products. And thanks to the mirrored outer surface, the system looks very presentable.

Elements of a gas chimney

Regardless of what kind of chimney is installed (except brick), it will definitely need additional elements. These include:

- an adapter that connects the heating boiler pipe and the chimney;

- telescopic pipes;

- inspection tee, which has a special fitting at the bottom used to remove condensate;

- bends;

- feedthrough pipe;

- main wall fastenings – clamp and bracket;

- tip having a conical shape.

Chimney pipes for gas boilers, photos of which you see below, necessarily consist of the listed elements.

Chimney for a gas boiler, photo

Requirements for a chimney for a gas boiler

The design of any chimney must comply with the requirements SNiP 2.04.05–91 and DBN V.2.5 – 20-2001. Otherwise, it will be performed incorrectly, and this will determine not only effective work gas boiler, but also the health and life of the residents of the house.

The design of any chimney must comply with the requirements SNiP 2.04.05–91 and DBN V.2.5 – 20-2001. Otherwise, it will be performed incorrectly, and this will determine not only effective work gas boiler, but also the health and life of the residents of the house.

Such rules must be approached with full responsibility, since ignoring them will result in trouble with the gas service, and even a fine. Any violation will still need to be redone according to established standards.

For normal operation of a chimney for a gas boiler, the requirements are as follows:

- Condensation must be drained using a special moisture collector installed at the bottom of the pipe.

- Chimneys for a gas boiler must have good draft, this allows the system to work more efficiently.

- To ensure good traction, the process of assembling the structure is very it is important to achieve maximum tightness of the connection of parts.

- The chimney must be vertical without any ledges. According to the rules, a slope of 30 degrees is allowed.

- A piece of pipe through which the gas boiler is connected to the chimney system, must always have a vertical section.

- With a room height of three meters the total length of horizontal connecting sections should not exceed this height.

- Particular attention is paid to the tight fit of structural parts at joints, achieving maximum tightness. This is necessary to ensure that hot gases do not penetrate beyond the chimney.

- The head of a chimney pipe that passes through the roof, should be no less than half a meter higher than her. If the roof is flat, then the head should be one meter higher.

The size of the chimney for a gas boiler must correspond to the following formula: P * L > S, where P is the perimeter of the pipe section, L is the length of the chimney, S is the internal surface area of the boiler.

How to install a chimney for a gas boiler in a private house? Is it possible to retrofit an old chimney? What is the difference between a chimney for a gas boiler?

Which technical requirements exist? You can find answers to these and other questions in this article.

What types of chimneys are there?

Before installing a gas boiler, you need to take care of the chimney installation. To do this, you can hire workers, or you can make a chimney with your own hands.

It's not difficult, although there are still certain requirements. To begin with, you should familiarize yourself with various types chimneys.

Chimneys can be made of:

- bricks;

- ceramic pipes;

- of stainless steel;

- coaxial chimney.

Brick chimney

A brick chimney is undoubtedly the cheapest option, but perhaps the most difficult to make with your own hands.

The fact is that a brick pipe has quite a decent weight. Therefore, its construction requires laying a foundation. But in the most brick pipe ventilation ducts can be installed.

The pipe laying should be done from solid ceramic bricks. To make the upper part of the pipe protruding above the roof surface, it is permissible to use facing bricks.

The requirements for brickwork are such that the thickness of the chimney wall can be half a brick.

But to ensure the strength and reliability of the pipe, it is recommended to lay it in at least one brick.

For a gas boiler, a smoke exhaust duct with a cross-section of half a brick will be sufficient. If desired, you can make it wider.

If you plan to insert a connecting tin box inside the channel, then it is best to make a channel with a cross-section of 20 by 20 cm.

To extend its service life, a brick chimney is installed along the internal wall of the house. The fact is that the durability of such a pipe is directly related to the high temperature of the smoke.

When temperature changes, the brick will begin to collapse. Additionally, maintaining proper temperature ensures better traction.

Ceramic pipes

Making a chimney from ceramic pipes is easier and faster to install yourself. This type of chimney is considered the most durable.

The smooth inner surface of the pipe reduces the chance of soot settling on it and makes it easier.

Some pipes are equipped with condensate drains, which prevents condensation from forming on the inner surface of the pipe.

The chimney itself is assembled from parts 0.5 - 1 m long. The upper edge of each part has a coupling - an extension into which the next part is inserted.

Ceramic pipes can be of different types:

- round ceramic pipes for installation in special concrete blocks;

- rectangular pipes for installation in brick;

- ceramic pipes in a steel casing;

- ready-made blocks with ceramic sleeve.

To make a pipe from round ceramic links, you need to purchase special reinforced concrete blocks.

They provide a cavity for installing ceramic pipes and seals. In addition, they have holes into which reinforcement is inserted during installation.

Concrete modules are produced with additional ventilation duct. Asbestos is used as a sealant when installing pipes. It helps protect nearby surfaces from fire.

Rectangular ceramic sleeves have a square cross-section of 20 by 20 cm and are designed for installation in a brick pipe.

The length of each individual section varies between 0.5 - 1 m. They are mounted in the same way as round ones, only you do not have to buy special blocks to install them.

Ceramic sleeves in a stainless steel housing are even easier to install.

Such a chimney is much lighter than a ceramic or brick one, so a foundation is not necessary. Pipes in a steel shell are connected to each other using clamps.

Ready-made concrete blocks are also available for sale, already equipped with a ceramic liner, a ventilation duct and holes for reinforcement.

Coaxial chimney

Unlike all the types described above, the coaxial chimney for a gas boiler has a horizontal outlet.

The convenience of such a chimney is that it is exhausted through the wall, and not through the roof, like a vertical chimney. To install it, simply drill a hole in the wall.

Such chimneys are designed according to the “pipe-in-pipe” principle. Here the possibility of supplying air to the boiler burner and removing smoke is immediately provided.

However, in our climate, a coaxial chimney for a gas boiler has one significant drawback. During the cold season, the air entering the burner significantly cools the exiting smoke.

As a result of temperature changes, condensation occurs. Freezing occurs on the outside of the pipe, which gradually clogs the passage and reduces draft.

Modern gas boilers are equipped with automatic shut-off, so carbon monoxide poisoning due to reduced draft does not threaten anyone.

But in order to resume operation of the boiler, the pipe will have to be cleaned of the ice that has formed in it.

Fewer problems arise with chimneys that use two separate pipes for air supply and exhaust. But such pipes are rarely found on sale.

Stainless steel pipe

The chimney is made of thick stainless steel and can be either vertical or horizontal. Installing such a pipe with your own hands is quite simple.

Disadvantages of a steel chimney:

- the service life of such a pipe is shorter than that of a brick or ceramic chimney;

- the cost is higher.

The advantages are simple, quick installation and lightweight design. A stainless steel pipe does not require installation of a foundation.

Since it is light in weight, it is suitable for wall mounting. Their inner surface is absolutely smooth, thanks to which soot almost does not appear.

If such a chimney becomes clogged, it can be easily cleaned and, if necessary, can be disassembled. Replacing used parts is also not difficult.

Stainless steel pipes can be either single-walled or double-walled, with insulation between the walls. It is better to use just such sandwich pipes.

Stainless steel chimneys can be used in rooms where a smoke exhaust pipe is not even provided for in the design. In this case, it is enough to lead the pipe to the street through the wall.

Single-wall steel pipes are used when converting an existing chimney for a gas boiler.

The gas boiler is connected to the chimney using steel pipe, which is brought out into the brick and fixed there.

How to choose the type of smoke exhaust structure?

To make the right choice, first of all you need to familiarize yourself with what requirements the manufacturer sets for the chimney.

When choosing the type of chimney for a specific boiler model, you must be guided by the following parameters:

- temperature of the exiting smoke;

- pressure and type of traction;

- the presence of channels for condensate drainage;

- recommended requirements for the distance to kitchen furniture and other household items.

Based on the combination of all these characteristics, you can choose which type of chimney is suitable. In addition to these parameters, each manufacturer has its own requirements for the required channel cross-section.

The diameter of the chimney for a gas boiler can only be determined by deciding on a specific model. Therefore, it is not advisable to arrange a smoke exhaust duct in advance.

In addition to the characteristics of the gas boiler, it is also necessary to take into account the characteristics of the building. It is not advisable to install a brick chimney in a panel country house or in a frame building.

For light buildings, a stainless steel or coaxial chimney is best suited. In addition to the fact that these types are relatively light in weight, they are easier to install with your own hands.

The following requirements apply to the chimney itself, regardless of what material was used in its construction:

- absolute tightness;

- presence of traction;

- vertical location of the outlet channel;

- if a vertical position is not possible, then the slope angle should not exceed 30°;

- smoothness of the inner surface of the pipe;

- presence of a hatch for cleaning;

- ability to reduce cravings;

- insulation of external areas.

The smoke duct must be completely sealed. Even a small amount of gases can cause poisoning.

To avoid this, it is necessary to check the channel for leaks and the presence of traction. The slope of the pipe from the vertical can be a factor that reduces traction.

The inner surface of the channel should not contribute to the accumulation of soot on its walls, for which it is necessary to check its smoothness.

This is especially true for brick chimneys, since in other types this problem occurs less frequently. The seams between the bricks must be perfectly even. You can also use a pipe insert.

Many people think that the smoke exhaust shaft starts from the boiler. This is wrong. The channel should fall below the boiler outlet by 30 - 50 cm.

This is necessary for installing a wall hatch, which will be used to clean the channel. Using it you can check the traction.

In some cases, it may be necessary to limit cravings. To do this, it is recommended to install a damper in the channel above the boiler.

A damper device is only necessary if the boiler is not equipped with a built-in damper. The damper can be replaced with an automatic limiter.

The greater the power of the gas boiler used, the larger the cross-section of the chimney duct and the height of the pipe should be. This will ensure good draft and proper operation of the boiler.

Security

During gusty winds, air from outside can enter the chimney, blocking the draft. In this case, if the boiler is not equipped with an automatic switch, the room will become smoky.

The same thing can happen during heavy rain or snowfall. To avoid the influence of atmospheric phenomena, the chimney outlet is covered with a special umbrella.

You can make an umbrella for a steel pipe from any piece of metal. You can also make a head for a brick channel.

The head structure provides smoke outlets from the side of the pipe, and the top itself is covered with a brick or plate.

Since most often the chimney is the most high point roofs, it is worth thinking about a lightning rod. Any metal structures have an increased degree of lightning hazard.

If the chimney is made of brick, then the lightning rod is manufactured as follows:

- metal fittings are mounted to the wall of the smoke duct;

- the fittings are connected by wire to the grounding system of the roof of the house;

- the grounding cable goes to metal plate, which is buried in the ground.

This grounding scheme can also be used when the smoke duct is made of metal. In this case, the role of the lightning rod is played by the metal head of the channel.

However, such grounding is only possible if the boiler is not equipped with an electronic processor.

To prevent the electronics from malfunctioning, the lightning rod should be made separately, at a distance of at least 50 cm from the chimney.

This grounding scheme provides that:

- when connecting the smoke exhaust duct and the grounding pole, no conductive materials are used;

- The lightning rod is located above the chimney.

To properly make a grounding system, you should use reinforcement with a cross-section of at least 10 mm.

When installing a smoke duct, you also need to worry about fire protection. The fire protection scheme provides for a 5 cm indentation when passing through the ceiling, which is filled with asbestos.

Fire safety rules require a minimum distance of 26 cm from walls, furniture and other objects that may catch fire.

Happy construction!